The construction equipment rental business model can be highly advantageous for all involved. The rental companies themselves stand to make a lot of money in this fast-growing, lucrative industry - while the companies renting equipment gain many advantages that can help improve their bottom line. On-site workers also benefit from having ready access to the most modern equipment and latest technologies needed to do their jobs.

When a construction business owner (CBO) rents equipment, they no longer have to worry about issues like repairs and routine maintenance, storage and transportation. The rental company takes care of all of this, freeing up huge amounts of time and resources for the CBO. Even though there’s a big convenience factor with renting, one of the major reasons for choosing to rent is reducing or eliminating CapEx. As an example, excavators, which are often needed only for a short time, can cost between $200,000 and $500,000 to purchase, compared to a daily rental rate of as little as a few hundred dollars.

However, deciding to rent versus buy equipment does come with some potential disadvantages. First, CBOs must weigh the convenience and short-term efficiencies of renting against the potential loss of valuable investment money in the long run. But even more pressing is the fact that CBOs may be “rolling the dice” in the sense that they cannot know for sure that the equipment and tools they need will be available when they need them. This is a particularly salient issue for construction companies specializing in projects like highways, public works and other structures that are prone to damage from unpredictable natural disasters. For these companies it’s nearly impossible to foresee what equipment will be needed, when and where.

The ability to track rental company equipment availability can vary from CBO to CBO, but generally these systems and processes are not well-automated and mature. This is because, compared to other industries, construction companies tend to be slow technology adopters. In fact, McKinsey & Company recently ranked the construction sector second to last out of 22 fields surveyed for digital readiness. This is likely due to several factors, including a prevalent attitude in construction of, ‘if it ain’t broke, don’t fix it.’ What’s the point of replacing paper spreadsheets with a more advanced digital system, some companies think, not understanding the greater efficiencies that automated, digitized processes can bring.

Even for a CBO who is modestly advanced technologically, on localized construction sites, equipment and tool tracking is often a struggle and can result in a substantial loss of work time. Incrementally, this downtime can snowball and lead to a big hit on overall project performance. This can be highly detrimental to both the rental company, which may be overseeing the renting of equipment to hundreds or even thousands of CBOs at once; and the CBO, not to mention on-site workers who depend heavily on having the right equipment and tools in the proper place when they are needed. Moreover, many isolated instances of lost time on projects can accumulate and be a big contributing factor to CBOs’ financial woes and - ultimately - an industry failure rate that exceeds 80 percent.

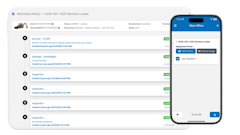

In construction, a comprehensive equipment management platform can be the key to ensuring transparency. This platform should be available to all stakeholders (rental company, CBO and on-site workers); integrate with stakeholders’ key platforms like e-commerce and financial management; give total transparency to equipment and tools’ location, usage, expense and efficiency; and ultimately, unsnarl the entire process for all parties involved.

In addition to transparency, automation is also important. CBOs, particularly those that may not be the most fervid technology adopters, need to clarify, simplify and automate the process of making equipment and tools available for their on-site workers. A big part of this can be the ordering of tools and equipment for major construction sites prior to construction starting. For example, the ordering process for on-site workers can be simplified as the equipment that was budgeted can be ordered from the e-commerce system with a few clicks, via automated basket collection. Reducing friction points and eliminating unnecessary steps are critical to a successful digital approach.

Transparency is needed for the success of any rental arrangement - be it cars, tools, real estate or something else, and the construction equipment rental business is no different. While this business model is poised for tremendous growth in the years to come, in a standard arrangement, there is still a lot of room for misunderstandings and for things to go wrong. A shared, comprehensive equipment management platform can serve as the basis for much-needed transparency and automation - fostering shared understanding and communication, and ensuring that all parties realize the maximum benefits.

![Herc 5745c08a34274 1 65ce4101dd187[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/06/herc5745c08a34274-1-65ce4101dd1871.UqeKvSiS04.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)