The summer months are a time of high production for construction professionals, with the warmer, drier weather conducive to more productive construction work. But the warmer weather also means additional planning and management for jobsite safety, particularly as it relates to heat. This summer is showing potential for extreme heat across the country, especially with the shift to El Nino. This creates a sense of urgency for safety managers to review and establish extreme heat monitoring and mitigation protocols.

DTN

DTN

When is Heat Considered “Extreme?”

Ready.gov defines extreme heat events as an extended period (two to three days) of high heat and humidity with temperatures above 90 degrees Fahrenheit. However, extreme heat can also be defined as any weather much hotter than average for a particular time and place. Extreme heat is more than an inconvenience, it is the leading weather-related killer in the United States. The Centers for Disease Control and Prevention (CDC) reports that in the U.S. an average of 702 deaths and more than 9,000 hospitalizations are related to heat. Among construction workers specifically, the U.S. Bureau of Labor Statistics reported 36 work-related deaths due to environmental heat exposure in 2021.

Scorching summer temperatures have become more common across the U.S. in recent decades and the EPA indicates that extreme heat events will become more frequent and intense in the future. As a result, the risk of heat-related illness and even death is expected to increase for nearly all populations, but outdoor workers are particularly susceptible.

Several organizations such as the U.S. Occupational Safety & Health Administration (OSHA), CDC and The National Association of Home Builders offers recommendations for employers about how to prevent heat-related illnesses, including using an acclimatization protocol, establishing a heat alert program and providing heat stress training. A critical component to planning and preventing heat stress is having the right weather intelligence.

DTN

DTN

Leveraging Weather Insights to Manage Extreme Heat Events

Having access to weather analytics is one of the most underused yet readily available resources that a construction safety team can use to prepare for the potential of extreme heat events. While extreme weather like tornadoes or severe thunderstorms are often associated with real-time radar and storm tracking information, those seeking insights into broader-reaching, long-term weather events like extreme heat can also benefit from longer range forecasts and the use of weather analytics. Integrating weather insights into job-site safety management can help construction safety teams make more informed decisions based on real-time and forecast information.

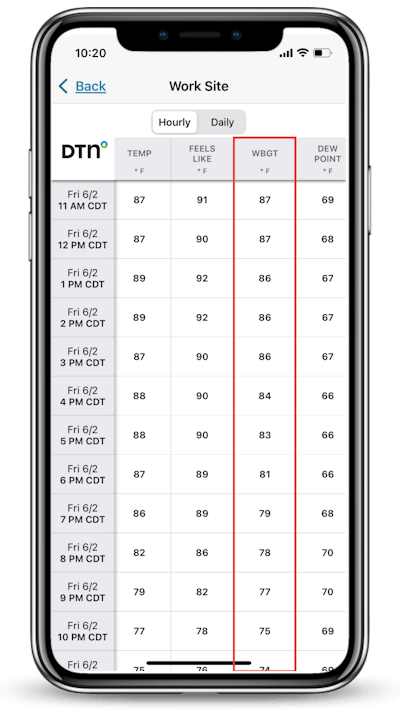

When making safety plans around extreme heat, there is much that the right weather resource can offer. In addition to assessing and reducing heat-related risks, establishing caution and warning thresholds are critical to having an effective mitigation plan. There are weather tools, that allow users to create location-specific alerts that are highly customizable, so weather conditions that are important to a specific jobsite — like extreme heat — can be established. In addition to alerts on the front end of a heat event, all-clear notifications can be automated and pushed to team members’ devices, so they know when temperatures return to thresholds established for normal worksite activity.

Knowing the Wet Bulb Globe Temperature

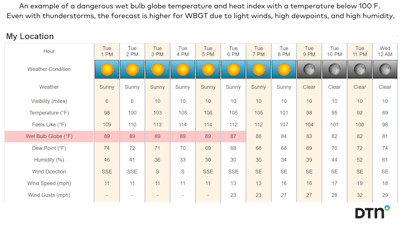

Most people are familiar with the heat index. It calculates humidity and temperature in shady areas to determine a “feels like” effect that the temperature will have on those outside. A more accurate way to measure heat stress on the body is the wet bulb globe temperature (WBGT).

The WBGT calculation incorporates multiple factors, including the temperature in direct sunlight, humidity, sun angle, wind speed, and cloud cover. Each of these factors plays a crucial role in determining heat stress on the human body. For example, when extreme heat combines with high humidity and light winds, it can become more risky than expected as the body’s natural cooling mechanism does not function as efficiently.

The U.S. Occupational Safety & Health Administration (OSHA) recommends using a WBGT monitor to measure workplace environmental heat. For construction crews, and other outside workers, knowing the WBGT is a more critical assessment of heat stress and necessary to keep employees safe in high temperatures. Outdoor workers are more susceptible to heat-related illnesses because evaporation can slow down, and the body works harder to maintain a normal temperature.

Measuring WBGT can be done in a variety of different ways. Site supervisors or other staff can use handheld devices explicitly designed to measure WBGT; they can reference charts or do manual calculations. Note, while measuring provides a point in time assessment, access to a WBGT forecast is more beneficial for construction companies to anticipate and prepare to address heat-related stress days in advance. On-site weather stations can also offer real-time data for WBGT readings and can monitor other weather events, such as severe weather and lightning.

Extreme Heat Days Expected Across the U.S.

While states such as Texas, Louisiana, Mississippi, Alabama, Georgia and Florida are most apt to record dangerous wet bulb globe temperatures, the weather pattern looks to spread bouts of extreme heat and humidity further north, with the shift to El Nino this summer. There is potential for higher than normal WBGT to become more prevalent, and while such heat and humidity are common for mid-July, there may be unusually long spans of extreme heat. Knowing when and where weather is happening in precise locations can help all response teams plan for the right equipment and people in place. Ideally a construction safety team will have access to the tools and counsel from weather experts to help understand the severity and timing of extreme temperature events, as well as other potential weather impacts.

For construction companies, it’s important to be prepared for all potential safety situations, especially silent killers like extreme heat. Exertional heat stroke has a 100% survival rate when quickly recognized and treated. It takes thoughtful planning as well as resources to help plan for and identify potential heat stress conditions and help keep construction crews safe during periods of extreme heat.