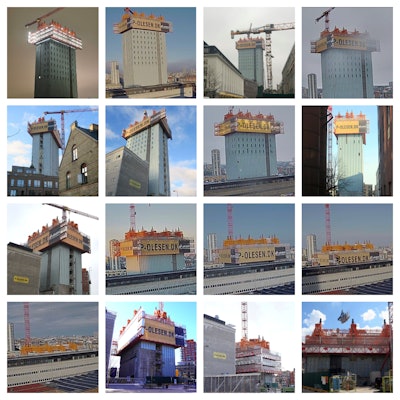

Engineering consultant Despe completed floor-by-floor demolition of the world headquarters of Danish multinational brewer, Carlsberg Group in Copenhagen, with a modular self-descending machine that contains all the material generated by demolition within its structure.

Contractor P. Olesen selected Despe for the demolition due to the unique nature of the 288-foot-tall building’s position, with adjacent school, stores and houses, and city regulations which required minimal disturbances including dust and noise. Rules differ between European and American cities, but global metropolises all have the same needs: that of growing vertically by replacing energy-consuming, structurally obsolete buildings with more-efficient, anti-seismic, extraordinary skyscrapers. Despe

Despe

Explosive demolition is banned in Europe’s most densely populated urban areas, so Despe innovated with a solution for controlled demolition of urban skyscrapers: TopDownWay, a modular self-descending machine that can be adapted to suit the requirements of all types of structures to be demolished. Its intelligent containment system retains glass, rubble, debris, noise, vibrations, dust, and sprayed water.

TopDownWay allows operators to work simultaneously on the three floors it occupies, carrying out multiple operations, such as dismantling façades, demolishing floor and removing debris. As the work progresses, the platform descends in a controlled manner until it reaches zero level, and the building has been completely demolished.

Assembling and disassembling the structure takes place quickly and safely: TopDownWay components are assembled on the ground, hoisted with a crane and connected to each other directly on the top of the skyscraper. After completing the demolition work, the structure is dismantled and disassembled.

Despe outlines several advantages to using the TopDownWay system:

- Improves safety for those who live in the city, safety for the surrounding buildings and monuments, safety for the roads, safety for people working at height, and safety for the environment.

- Improves speed. For a 25-floor building, Despe’s system can be assembled in 20 days and complete the demolition in three months. Traditional methods with scaffolding increases assembly time to three months and demolition time to six months.

- TopDownWay has zero environmental impact, which means 100% protection against rubble, debris, dust, noise, vibrations. The system adheres perfectly to the structure to be demolished and ensures 100% containment.

- Improves visibility. Skyscraper demolition does not go unnoticed, but with this system we avoid total coverage of the structure because only the three upper floors are enclosed within the system itself. This space, which is highly visible but not cumbersome, can be used for advertising day and night.

Despe is a family business headquartered in Italy, operating globally in the demolition, engineering consulting, decommissioning and reclamation sectors. The company has made a name for itself in the U.S. with its self-climbing Kokoon, providing structure around the steel frame of the in-progress Two Manhattan West in New York City, and before that, 50 Hudson Yards.  Despe

Despe