The elevator installer wants $50,000 more than his bid price because the concrete elevator walls are too close together. The manufactured stair installer says the embed plates in the concrete are not flush with the wall and wants an extra $25,000 to install the stairs. The curtain wall installer says the edge of the concrete floors don't line up and he'll need to use adjustable connections that cost $75,000 more. And the construction manager, of course, says no problem for any of these changes because he will back-charge the concrete contractor. Sound familiar?

Evaluating tolerance compatibility at the interface between concrete and other building systems is challenging because materials, products, and elements that connect to the concrete often have tolerances that differ from those for concrete. Coordinating these different tolerances early in the project reduces problems that can impact quality, cost, and schedule during construction. Assistance for these issues is available, however, in ACI 117.1R-14 "Guide for Tolerance Compatibility in Concrete Construction."

Architects and engineers can use the recommendations in this guide to accommodate individual material, product, and element tolerances at their interface with concrete construction. Contractors can use the recommendations in this guide to mitigate tolerance conflicts during the construction phase.

The Guide strongly recommends a pre-construction tolerance coordination meeting that includes the owner, general contractor, construction manager, architect/engineer, concrete contractor, and all other subcontractors whose work will interface with concrete construction elements. Attendees should address the anticipated tolerance compatibility questions and conflicts applicable to their work so that tolerance issues are identified and resolved before concrete construction begins. Resolution of tolerance issues after contract award may result in changes having to be made to the contract terms, which may affect one or more of the parties involved.

On most projects, the architect/engineer is responsible for coordinating tolerances for the construction. It is critical that the architect/engineer account for tolerance requirements in the contract documents and develop details that provide for the required clearances and adjustability between concrete and other construction elements. When specific industry standard tolerances do not exist, the architect/engineer should coordinate with individual manufacturers and the general contractors, as required, to develop details that provide for individual and accumulated tolerances.

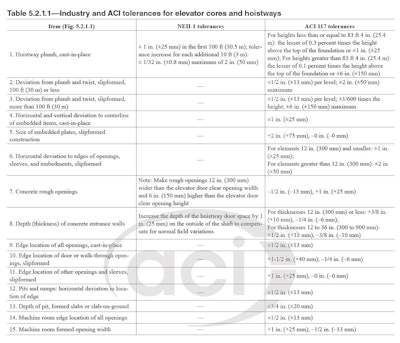

But what information is in ACI 117.1R-14, and how is it presented? The summary of Chapter 5 shows the topics that the reader will find useful. As an example, the Table and accompanying figure show the tolerances for elevators shafts for both ACI and NEII – National Elevator Industry Inc. (NEII-1). NEII-1 tolerances are tighter than those established by ACI 117, as shown in Table 5.2.1.1. For example, NEII-1 requires a tolerance of ±1 inch for the first 100 feet instead of ±1 inch for the first 83 feet, 4 inches. set by ACI 117. The NEII-1 limits the total tolerance for taller structures to ±2 inches, whereas ACI allows a ±6 inch tolerance. This guide goes further by providing both design and construction strategies for handling the tolerance differences.

Contractors should get a copy of this guide and use it for tolerance pre-construction meetings. To purchase a copy of this document go to www.concrete.org.