Question: It has come to my attention that the concrete contractor working on my new home used concrete that was air-entrained for the basement and garage slabs. The research I’ve done suggests this is bad. Is it true or false?

Answer: Research via the Internet can open a mix of challenges, no matter the subject matter of the inquiry. You can literally find opinions and research to support any angle and much of it is based on the way you ask the question as well as not being thorough in qualifying sources. The issue of air-entrainment continues to be one of the fastest growing technical concerns found in the concrete industry. This is due to concrete codes having generic exposure class requirements that are more often misunderstood and over-analyzed to be conservative. A reputable craftsman, producer and contractor should always be consulted in combination with the research and it never hurts to go directly to sources like the Concrete Foundations Association, American Concrete Institute and the American Society of Concrete Contractors for technical documents providing further qualified support.

The Code

Whether considering ACI 3181 or ACI 3322, classes have been assigned to concrete situations based on the severity of exposure to freezing temperatures and the likelihood of being in a saturated condition. The combination of the two determine the specification or requirement for the use of air-entrainment to use. Table 5.2.1 of ACI 332-14 establishes descriptions for the four classes of the category RF, which stands for resistance to freezing as follows:

Table 5.2.1 of ACI 332-14 establishes descriptions for the four classes of the category RF, which stands for resistance to freezing.American Concrete Institute

Table 5.2.1 of ACI 332-14 establishes descriptions for the four classes of the category RF, which stands for resistance to freezing.American Concrete Institute

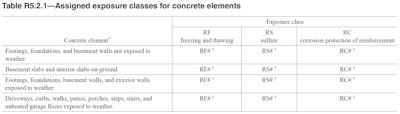

The additive conditions of this table help the user/specifier determine where the concrete is to be placed in relationship to the exposure of the two primary conditions, freeze-thaw cycles and saturation. Notice there isn’t a consideration for just saturation for the RF category. The code then provides a suggested table for a project where the exposure classes can be selected for each category. This is a commentary table that can be added to a specification document or in general notes in a drawing set and appears as follows:

The code then provides a suggested table for a project where the exposure classes can be selected for each category. This is a commentary table that can be added to a specification document or in general notes in a drawing set.American Concrete Institute

The code then provides a suggested table for a project where the exposure classes can be selected for each category. This is a commentary table that can be added to a specification document or in general notes in a drawing set.American Concrete Institute

In applying the code to this discussion, it should be clear to the user that the basement slab and an interior slab will be classified the same and a garage slab would be considered an interior slab unless it was unheated and exposed to weather. Since after further inquiry it was determined that the garage floor was protected by a garage door, despite it not being heated, the exposure is not severe enough to separate it as a driveway. In reviewing the first table for class severity, RF0 would be assigned automatically to a basement slab since it has no exposure to freezing and thawing cycles. The garage slab now must be determined whether it is has the potential to be in a saturated condition “while” exposed to freeze-thaw cycles. Given that garage slab nearly always receives a hard-troweled surface, that which has been set with a machine that burnishes the surface, the porosity has been eliminated and saturation is not possible. Although deicing salts will likely be carried into the garage, these will sit on the surface of the slab while the water evaporates or dries. It might be difficult to assign an RF0 class to the garage due to it being an unheated floor and the presence of moisture and even deicing salts then offers either an RF1 or RF3 class. To move the discussion along, the RF0 class requires no air-entrainment according to ACI 332-14 and both the RF1 and RF3 classes have air-entrainment requirements based on the maximum aggregate size. However, what this table does not account for is the hard-troweled surface and the barrier to absorption it provides. Furthermore, the code does not address the impact of air-entrainment conflicting with the finishing process.

Technical Resources

One of the important document references to understand the importance of considering the finishing characteristics impacting air-entrainment is ASCC Position Statement #13. This document has purposed direction to the contractor or the specifier explaining the risks associated with selecting air-entrainment exposure classes for such slabs. These risks include:

- Risk of concrete scaling and possible repair cost due to cold-weather exposure.

- Cost of air-entrained versus non-air entrained concrete.

- Increased risk of delamination and blistering, and possible repair cost when the surface is machine troweled.

- Reduction in surface air content and change in hardened air void parameters when the surface is machine troweled.

The presence of air-entrainment when slabs are to be finished creates a conflict between the intended durability and the resulting durability. This document brings two additional references to light for important direction in considering the exposure versus the performance:

- The optional requirements checklist of ACI 3014 states that intentionally entrained air should not be incorporated in normal weight concrete slabs that require a dense, polished, machine-troweled surface.

- ACI 302.1R5 states that entrained air is not recommended for concrete to be given a smooth, dense, hard-troweled finish.

The document concludes that the position of the contractor should be to only hard-trowel air-entrained concrete if a) required by the specification (which comes from a code interpretation)…and…only with the acknowledgement by the owner or representative of the risks and that the specifier is to bear the responsibility.

Conclusion

Quality concrete is, or should be, desired by everyone in the process of new construction. It should not be surprising that professional contractors and ready mix producers want the installation to perform the very best. It is understood that the designer/specifier expects concrete to achieve and maintain the aesthetic and performance for the project. It is also undeniable that the owner anticipates their investment to achieve a lasting quality for their investment. Therefore, the success must be predicated on communication for the intent, means and methods and options to pursue in order to achieve satisfaction for all three of these interests. The use of air-entrainment should be carefully considered and monitored for the actual conditions of both construction and exposure to establish appropriateness. It should not be used as a conservative measure for the protection of the unknown.

CFA is committed to creating greater awareness and better education on the technical aspects of the concrete industry. Rather than making assumptions on detailing or relying on the concrete producer alone to make decisions for sufficient concrete design, contractors need to recognize the resources available to them and spend enough time to understand them. This is a primary reason for the creation of the ACI/CFA Residential Foundation Technician Certification, to demonstrate and verify command of these technical resources for use in projects. This certification is also the first step toward the ability of a company to achieve CFA Certified Foundation Company status.

Want to know more? Contact CFA Executive Director, Jim Baty at 866-232-9255 or by email at [email protected]. The Concrete Foundations Association mission is to support the cast-in-place contractor as the voice and recognized authority for the residential concrete industry.

References:

1. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org

2. Residential Code Requirements for Structural Concrete (ACI 332-14) and Commentary published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org

3. Hard Trowel Finish on Air-entrained concrete (Position Statement #1) published by the American Society of Concrete Contractors, 2025 S. Brentwood Blvd, Suite 105, St. Louis, MO 63144 | Phone: 314-962-0210 | www.ascconline.org

4. Specification for Structural Concrete (ACI 301-16) published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org

5. Guide to Concrete Floor and Slab Construction (ACI 302R-15) published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org