Concrete dowel drilling isn’t a dangerous process. However, as with any piece of equipment, negligent operation or a complete disregard for safe practices can create serious hazards. Just like ignoring proper operational sequences, ignoring safe operation practices may put more than just the operator in jeopardy; it can also lead to a damaged drill or component.

Begin with the basics, proper work attire. Workers should wear earplugs to prevent damage from drill and air compressor noise. Debris flies during drilling, so the operator and other workers on the site must wear safety glasses and hardhats, as well.

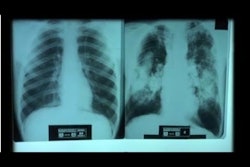

Concrete dust is often emitted during the process too, so dust masks are a must-have for all on-site workers. But concrete dust can pose other risks too. If large amounts are emitted, the dust can cloud a site and create a low-visibility environment for workers or, worse, for nearby live traffic. To help minimize dust emissions, many companies offer pneumatic drills with dust suppression kits or dust collection systems. Dust suppression kits include a spray nozzle, which attaches to each drill system and sprays water on the bit as it’s drilling. A dust collection system runs on the same compressor as the drill and vacuums dust as it’s emitted. The system’s dust collection head typically mounts to the end of the bit guide, where the bit penetrates the concrete. The vacuum draws out dust straight from the hole and into the collection bag. Both systems keep airborne dust and related hazards to a minimum.

Safe drilling starts with the proper PPE: earplugs, safety glasses and hardhats.

Safe drilling starts with the proper PPE: earplugs, safety glasses and hardhats.

A few areas of the drill pose specific danger to operators. Every drill has pinch points where fingers, hands or limbs can become caught. A primary example is the carriage assembly. Keep clear of the carriage assembly to avoid being caught between the carriage and frame. When moving a drill, be sure the carriage lock is set to prevent the assembly from sliding onto fingers and hands.

Furthermore, improperly moving a drill can cause operator strain or a serious accident. When moving a drill on the ground, operators should use the unit’s designated handles. If the drill is lifted improperly, it could cause a strained back or other muscle and joint problems. If a drill needs to be moved a greater distance, a lifting device might be necessary. In this case, use a properly weight-rated strap or chain and attach it to the drill’s lifting bale. Be sure the carriage lock is in place.

Compressed air is required to run a pneumatic drill and the great pressure can pose safety issues. The operator should monitor the air compressor’s gauge to be sure pressure doesn’t inch up too high. If the pressure is too high, it can damage the drill. This may void the warranty altogether, but even more detrimental is the lost productivity as a result of downtime. Additionally, before moving, disconnecting the air hose or any parts or disassembling the unit, the operator must first shut off the air supply and bleed off any air in the system. Taking just a few minutes to do so will help eliminate potential injuries.

Article by Randy Stevens, Vice President of Sales, E-Z Drill, Inc.

Originally published in October 2013.

![Fcp Racatac Chair 10893876[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/10/fcp-racatac-chair-108938761.10l0At5WXv.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Fcp Racatac Chair 10893876[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/10/fcp-racatac-chair-108938761.10l0At5WXv.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)