The results of a recent, soon-to-be-released ASTM Precision and Bias interlaboratory study may prove extremely important for industry specialists who install flooring and/or test the moisture condition of concrete floor slabs.

Clearly, when testing for moisture, the preference should be to use a method that provides reliable, accurate results, and is relatively fast and simple to perform. Scientific studies in recent decades have consistently shown that relative humidity (RH) testing is the most accurate and reliable method for assessing the true moisture condition of a concrete slab.

But what about the time needed for ensuring a reliable, accurate test?

Currently, the ASTM F2170 Standard mandates that concrete floor slabs be at service conditions at least 48 hours before testing RH with in situ probes. After that, the probes are inserted to a depth equal to 40 percent of the slab thickness (when drying from one side) and allowed to acclimate for 72 hours before taking the RH reading.

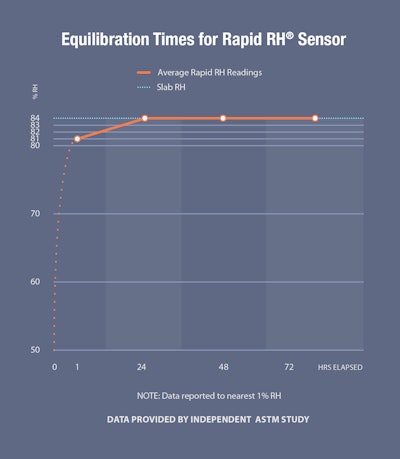

However, this new ASTM Precision and Bias study shows that when using in situ probes to measure the RH, moisture equilibrium with the surrounding concrete is achieved in 24 hours.

Until now, it had been thought that 72 hours was the time needed for the RH sensor to fully acclimate within the freshly drilled concrete hole.

ASTM’s P&B Study: Critical Information for Contractors

Briefly, by way of background: in the study, the laboratory tested several manufacturers’ RH products, taking temperature and RH readings at various times from one hour to 72 hours.

The results of the study indicated that the 24-hour readings for the tested RH sensors were essentially identical with the 72-hour readings. Some slight variation occurred, but it fell well within the acceptable range as laid out by the ASTM Standard.

In other words, the test showed, that when you conduct RH testing properly in the field, you can confidently and soundly know what the RH measurement at 72 hours will be, as it will essentially be the same as the 24-hour measurement.

Of course, you still need to take measurements at 72 hours to fulfill the ASTM Standard’s requirements. But there is no longer a doubt about how long you must wait to get the necessary data to help you move forward on your project.

Evidence to Support a Change

The ASTM Precision and Bias study clearly reveals that RH readings taken with in situ probes at 24 hours are essentially the same as those taken at 72 hours. This important finding provides convincing evidence to support a change in the ASTM F2170 Standard from 72 hours equilibration time to 24 hours. Based on the study’s findings, this should in no way sacrifice the accuracy and reliability of the RH test. But it would give people in the concrete and flooring industry the often much-needed opportunity to accelerate their projects and make important business decisions in a more timely manner. The study also found that “early” readings taken with the Rapid RH sensors provided a reliable, accurate indication of the final 72-hour reading.

Ed. Note: For more information about the independent ASTM Precision and Bias study and its findings, contact Wagner Meters at 1-800-634-9961.

![[VIDEO] Wagner Meters DataMaster App Helps Contractors Document Concrete Moisture in Floors](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/02/default.56b12de533659.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)