Construction project planning teams can spend years developing what looks like the perfect plan. However, once the project transitions into execution, even the best-crafted plans are tested by real-world conditions, making deviations from the original plan almost inevitable. The ability to adapt and adjust to changes is what makes or breaks a job.

Artificial intelligence (AI) is beginning to reshape how teams approach construction project planning, execution, and delivery.

The Intricacies of Concrete Work

Concrete construction is high-stakes: once a pour begins, there’s no room for error. Missteps in logistics, scheduling oversight, assumptions with sequencing, or crew readiness can lead to costly rework, delays, and significant cost overruns.

The reality of the age-old trade is that it involves hundreds, sometimes thousands, of interconnected activities. Often, the question isn’t what to do next, it’s evaluating what’s the best option when labor availability and utilization, equipment access, weather, site constraints, and conditions — all come into play.

Industry-specific AI tools are making it easier to connect project layers with on-site conditions and generate actionable insights from connected data.

For example, AI-driven software can analyze schedules to identify risks and predict potential incidents. The advancing field of computer vision and imaging technology can automatically capture site progress. Embedded sensors in concrete pour combined with AI platforms can monitor curing conditions and predict in-situ strength gain.

Generative scheduling technology powered by AI allows teams to rapidly simulate various scheduling scenarios in seconds, giving them the information they need to make faster, more accurate decisions.

Still, AI isn't a magic bullet as its effectiveness depends on the quality of the data it receives. The technology can't fix disorganized processes, scattered input, or disconnected teams.

ALICE Technologies

ALICE Technologies

The Digital Efficiency Landscape

Not every contractor or project has the time, budget, or personnel to maintain a fully integrated 3D model throughout construction.

Super Bowl-winning quarterbacks are masters of the handoffs, giving the running back the best chance to gain yardage. Construction projects rely on similar coordination. When handoffs between crews break down or get derailed by roadblocks, productivity suffers.

At its core, a construction project is first a visual challenge, and construction professionals first think about the process and resolution visually. However, the industry is still largely Gantt-driven. Only a few can effectively read and understand a Gantt schedule. The rest prefer to rely on visuals, like printed plans, sticky notes, diagrams, or sophisticated 3D models.

For example, a concrete contractor may identify their task in the schedule, then manually search for the corresponding area in the drawings, print it out, mark it up, and coordinate with others — all without instantly knowing whether the plan has been updated. This manual process is slow, siloed, and prone to miscommunication. It leaves too much room for error, especially when handoff and coordination are critical, like during a concrete pour.

It's common for the next subcontractors to miss their cues, bringing progress to a standstill. You’ll often hear, "I didn't know I needed to be there" or "I was waiting for the last crew to finish up."

On the other hand, 3D building information models (BIM) can be powerful, but they come at a high cost. Creating and maintaining accurate BIM models requires dedicated teams, steep learning curves, and constant coordination. Any changes to the project must be reflected in the model — an effort that could lead to downtime.

More about AI on ForConstructionPros.comThe AI Advantage - how self-performing concrete contractors can benefit from generative AI. 3 Ways Parametric AI Will Change Commercial Preconstruction - Parametric AI enables a preconstruction professional to quickly change various parameters of a project. AI Is Reshaping Construction - The construction industry faces labor shortages and rising costs — but AI is stepping in. |

Additionally, not every contractor or project has the time, budget, or personnel to maintain a fully integrated 3D model throughout construction. And for trade partners, the ROI on accessing and editing a BIM model may not justify the effort, especially if they just need to understand task sequencing, site layout, or crew handoffs in real time.

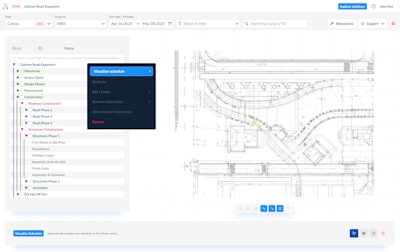

What teams need is something in between: a lightweight, intuitive way to visualize the schedule spatially, without the cost and complexity of a full BIM model. This is where visual planning tools can significantly improve the process with immediate impacts on operational efficiencies and gains. Such scheduling software would enable project teams to upload a schedule file and project drawings to start visualizing the Gantt in 2D over a site layout.

In this scenario, teams would be able to color-code scopes by crew, equipment, activity, or phases. Filters help teams focus on what matters most, such as the critical path, making it easier to plan, coordinate, and communicate with other subs. This also enables teams to leverage AI to optimize the critical path and explore alternative sequencing options for faster project durations or reduced costs based on specific objectives.

Simple visual planning software also helps communicate schedules, visually, to non-scheduling field professionals, like the forepersons, superintendents, and project engineers who are building the job on-site. Crews can use them to understand the day-to-day schedule, inform the team of changes, communicate with subs, and show how changes will impact delivery.

A digital visual workspace also allows the organization of field photos to create as-built records, forming the foundation of a digital twin, but in 2D.

ALICE Technologies

ALICE Technologies

AI Scenarios Specific to Concrete Contractors

AI isn't here to replace humans; it’s here to empower them.

These days, inefficiencies usually stem from a lack of time or adequate technology employed by the GC for accurate planning and optimizing the resources, materials, and time.

Since concrete contractors are at the mercy of the overall schedule and scope, coupled with management of the concrete product itself, they rely on experience and instinct to estimate resource allocation and utilization, such as formwork, crews, or equipment. But that can lead to over- or underutilization of resources.

Industry-specific AI tools can help concrete contractors reduce inefficiencies and improve profit margins both in the field and even at the bidding phase.

One example: a concrete subcontractor working on a 60-ft. below-grade excavation. The subcontractor needed to determine the right sequencing and formwork quantity required to complete the job, price the work, and submit a competitive bid. Initially, they estimated they’d need ten sets of formwork. By utilizing AI tools, they realized they could achieve the same result with six.

That 40 percent reduction helped the contractor submit a lower bid, win the job, and increase their profit margin.

In another example, a developer used AI to evaluate and compare the impact of using quick-set versus standard concrete on a high-rise residential project. The analysis revealed that quick-set concrete could reduce project duration by 50 days and lower overall costs by 3.5 percent, despite its higher material price.

An increasing number of contractors are also using AI software like OpenSpace to analyze images of poured concrete to compare as-built concrete work to design, spot missing elements, uneven pours, or layout errors in real-time.

Additionally, predictive analytics tools use historical safety data and site imagery to identify high-risk activities. For example, alerts can flag when sequencing leads to congested zones during critical pour windows.

The takeaway? AI isn't here to replace humans; it’s here to empower them.

AI gives teams the ability to make better decisions, faster. Without it, concrete contractors are left solving high-stakes problems by hand, under pressure, and often with incomplete data. With it, they can focus their time on strategic decision-making.

ALICE Technologies

ALICE Technologies

AI Enables Proactive Jobsite Management

Whether the goal is to minimize downtime, hit a critical milestone, or control costs, AI can recommend adjustments based on the team’s real priorities.

Concrete work is unpredictable. Historically, decisions and pivots in planning and on the jobsites have been made reactively–often on the fly with limited data. To recover the schedule, teams often throw additional labor or materials at the problem. While that may help regain momentum in the short term, it isn’t always efficient and can waste resources. Not every task benefits from more people or equipment.

The challenge is determining where extra resources will actually make a difference. That kind of analysis can take weeks using traditional tools. Meanwhile, the project slips further behind, and the scheduler gets pulled away from other work.

AI tools can crunch the numbers and provide construction teams with the fastest iteration to minimize downtime in minutes. AI helps teams pinpoint the most effective path forward and suggests the ideal changes to achieve the most significant productivity gain, so that teams find the sweet spot in terms of efficiency. Whether the goal is to minimize downtime, hit a critical milestone, or control costs, AI can recommend adjustments based on the team’s real priorities.

And if the team has different goals, such as cost or milestones? The AI tool can simulate thousands of "what-if" scenarios in minutes, identifying the most efficient and risk-aware strategy based on the project's goals. Ultimately, professionals on the ground make the call about how to proceed.

Every successful construction project starts with a plan and schedule that is clearly communicated to all involved. Maximizing success, however, requires adapting and adjusting to the inevitable changes. Industry-specific AI helps teams, including concrete contractors, make smart job site decisions that increase productivity.