In November 2025, CarbonCure Technologies was able to achieve a notable milestone for the concrete construction industry. More than 83.6 million cubic yards (or 10 million truckloads) of the CarbonCure product have been produced to date throughout its producer network. According to the company, that’s the equivalent of enough concrete to build all 30 NFL stadiums — twice. Further, 10 million concrete trucks lined up bumper to bumper would form a line from New York to Los Angeles (and back) more than 10 times.

Concrete Contractor connected with interim CEO Kristal Kaye and Jason Campbell, commercial director for North America, for their outlook on decarbonizing the concrete industry.

Q. What are the top 3 reasons why the concrete industry is a challenging sector to decarbonize?

Jason CampbellCarbonCure Technologies

Jason CampbellCarbonCure Technologies

Specifically, innovation and efforts to make concrete more sustainable are hindered by regulatory requirements for prescriptive concrete specifications. The outdated practice of using prescriptive specifications originated decades ago when concrete production quality control standards were not as robust as they are today.

Switching to performance-based standards for concrete procurement empowers concrete producers to provide the best products that meet the required performance requirements, such as strength, durability, workability and compliance with the engineering needs of the particular application of the concrete. It also creates the opportunity for producers to introduce new innovations and increase carbon savings during concrete manufacturing.

Kristal KayeCarbonCure Technologies

Kristal KayeCarbonCure Technologies

Q. As end users of the concrete product, what role do concrete contractors have in affecting the impact of cement and concrete production to our environment?

Kaye: Concrete contractors are on the frontlines of the built environment, and they have significant influence over the industry’s decarbonization trajectory. Concrete and the concrete industry has been unfairly characterized for so long as ‘the bad guy.’ Imagine if the world actually recognized concrete as both an essential building material and as a climate solution. Imagine every yard of concrete poured for that new data center or road or hospital locking down CO2 so it will never reach the atmosphere while also reducing cement emissions to make this an environmental win-win.

Unfortunately, we have seen project stakeholders create barriers to innovation because they prefer the status quo, even if it results in excessive amounts of cement use, higher costs and preventable emissions. By welcoming performance-based specifications or simply inquiring about lower-carbon concrete products, contractors can send a powerful demand signal upstream. This would encourage all concrete and cement manufacturers to adopt solutions that reduce emissions and reward producers taking the lead. Contractors' day-to-day choices directly shape which materials are used on jobsites, and therefore help determine the carbon footprint of our buildings and infrastructure.

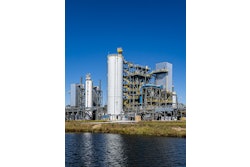

1072 West PeachtreeCarbonCure Technologies

1072 West PeachtreeCarbonCure Technologies

Q. As CEO, in what ways do you hope to impact the concrete industry in the coming future?

Kaye: We’re in hundreds of plants across nearly 30 countries and currently approaching 700,000 metric tons of carbon savings to date. That can be tracked, in real-time, on our homepage. It’s a massive number, and we’re proud of that impact but, with 100,000 concrete plants around the world, we see so much more opportunity. Our mission is to empower cement and concrete producers with technologies and strategies to achieve the industry's net zero commitment by 2050.

The complete decarbonization of concrete manufacturing will require all hands on deck and all the tools in our toolbox, with CarbonCure stacked on top of a variety of technologies, materials, and methods. These solution stacks will likely vary from region to region. For our part, we are focused on the continued enhancement and evolution of our tech and collaboration with other mission-aligned partners, including industry, peer innovators, Big Tech, academia, government, and civil society. This means end users of our concrete — across commercial, residential, and infrastructure projects — and carbon credit buyers, with that revenue helping to neutralize costs, incentivize industry adoption, and accelerate our global scale.

Q. What notable low-carbon concrete projects stand out for you? Why do these projects stand out?

Kaye: “HQ2,” Amazon's second headquarters in Arlington, Virginia near D.C., grabs a lot of headlines, considering the significance of that building and Amazon’s pioneering leadership on embodied carbon reductions. Our producer partners, Vulcan Materials and Miller & Long, leaned into that innovation opportunity, extensively collaborating with HQ2’s designers and contractors and stacking CarbonCure with other cement replacements to deliver a 20 percent reduction in HQ’s concrete carbon footprint.

The Amazon HQ2 building was constructed with CarbonCure concrete.CarbonCure Technologies

The Amazon HQ2 building was constructed with CarbonCure concrete.CarbonCure Technologies

At 60 stories, the new 1072 West Peachtree skyscraper in Atlanta—built by our friends at Turner Construction and supplied by our producer partner Thomas Concrete — just topped out a couple weeks ago. (Editor's Note: Responses to this interview were provided late Fall 2025.) It’s now the tallest residential building in the city, the tallest Atlanta skyscraper in three decades and — most exciting for CarbonCure — the tallest tower in the world built with carbon-mineralized concrete.

Campbell: While these notable projects get a lot of attention, CarbonCure is not just used in high-profile projects. If you live near one of the hundreds of concrete plants across North America or around the world that use CarbonCure's technologies, you've probably seen, walked or driven on CarbonCure concrete without even realizing it. The 10 million loads of concrete that our producer partners have supplied to date have built thousands of projects of all scopes and sizes: runways, driveways, sidewalks, schools, homes and high rises, distribution centers, and data centers. In particular, due to the demand for greener building materials, we’re seeing CarbonCure producers supplying a rapidly growing number of data centers.

We’re seeing a major opportunity for contractors as data center construction surges worldwide. These facilities require enormous volumes of concrete, and the tech companies behind them are under intense pressure to cut Scope 3 emissions quickly, not five or ten years from now. That creates a powerful pull for low-carbon materials on every bid package.

Contractors who can demonstrate the use of proven, lower-carbon concrete solutions are better positioned to win this wave of work. With technologies like CarbonCure, producers can deliver the same strength, performance, and schedule reliability that data center projects demand, but with significantly reduced embodied carbon.

Contractors don’t have to change workflows. They simply gain a competitive edge in a market where sustainability has become a procurement requirement, not a nice-to-have. In short, data centers are driving one of the biggest near-term decarbonization opportunities in construction, and concrete contractors who lean into these material innovations will be the ones best positioned to capture it.

Concrete contractors finishing the concrete at the Amazon HQ2 facility. CarbonCure Technologies

Concrete contractors finishing the concrete at the Amazon HQ2 facility. CarbonCure Technologies

Q. What are carbon credits? How do they affect the concrete contractor?

Kaye: CarbonCure carbon credits represent one metric ton of verified, permanent CO₂ storage, through carbon mineralization, and CO₂ reduction, resulting from enhanced cement efficiency. CarbonCure generates and sells carbon credits to corporate buyers in the voluntary carbon market who are targeting climate goals or offsetting their hard-to-abate emissions. The environmental attribute then belongs to that third-party buyer. CarbonCure shares the carbon credit revenue with our concrete industry partners to incentivize their adoption of our solution and make licensing and using our technologies cost-neutral. For contractors, there is no effect. It’s the same high-quality concrete, with no compromises on performance and with no green premium.

Q. What are some of the most impactful changes in concrete from the last decade plus?

Kaye: Over the past decade, the biggest shift has been the rise of a wide spectrum of innovators and solutions for reducing concrete’s embodied carbon. Green concrete is no longer a niche concept. It’s becoming standard practice.

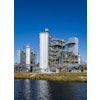

Ozinga Concrete using CarbonCure at an Illinois concrete plant.CarbonCure Technologies

Ozinga Concrete using CarbonCure at an Illinois concrete plant.CarbonCure Technologies

Q. How do you think contractors can take advantage of these changes?

Campbell: Contractors can get ahead of the curve, leveraging their experience with concrete innovation or green building expertise to win projects, meet building owners' sustainability expectations, and stay competitive in a market where low embodied carbon is increasingly desired, if not required. By supporting lower-carbon mixes, partnering with forward-thinking producers, and integrating these materials into bids, contractors can achieve market differentiation. Importantly, many solutions, including CarbonCure, don’t require changes to workflow or performance trade-offs. Contractors can simply build as they always have, with a lighter carbon footprint.

Q. How do you see concrete changing in the future? What does concrete construction look like 5 years from now?

Kaye: After reaching our 10 millionth truckload of CarbonCure concrete, it's clear that rapid commercial adoption is possible. Looking forward, I want to support producers and contractors with tools, data, and trust so low-carbon concrete becomes the default choice everywhere.

That said, the end goal is not changing concrete or disrupting construction. We want to enable the same production of high-quality, cost-effective, reliable concrete products, just with a lower carbon footprint. Our focus is on progress without disruption: empowering producers and contractors to keep doing what they do best, delivering this essential product while efficiently cutting its emissions.

The concrete of tomorrow will feel familiar in every way that matters, except for its dramatically smaller carbon footprint. Fundamentally, the material, the plant operations, and the industry should look the same, but the legacy being built will make a world of difference.