Let's say you have a project indoors. The emissions caused by a gasoline-, diesel-, or propane-powered mixer/pump would force you to figure out a way to get the slurry to where you need it. What if you could bring that machine inside? What if you could set it alongside your workers and work the floor your on as well as the 10 floors above? With the latest from Strong Manufacturing, you can.

As an innovator in the design and manufacturing of mixing and pumping equipment of cement and gypsum-based products, the company has developed a solution that allows a contractor to not only run the machine inside but it even fits through the door. The company sees its innovative spirit within its 60+ years of experience and versatility—enhancing the company's ability to design specialty equipment for any need. Case in point, they are the original designer and manufacturer of the first automated mixer for lightweight concrete for aircraft arrestor runway systems.

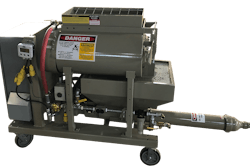

It's this innovative mentality that inspired Strong to provide a zero-emission solution to their customers to be able to work indoors - the FloorMate80E. “It’s not just a pump. It’s a mixer and a pump together, like a mobile batch plant,” says Jesse Downs, sales representative of Strong Manufacturing.

“With it being electrical, all they have to do is find one plug,” he says. Instead of a diesel engine or hydraulic pump, the FloorMate80E can operate on a standard 220 single-phase outlet plug—the same outlet that runs a household oven or dryer. If no such electric connection exists, the FloorMate80E can run off of a 220V single phase 30-amp generator via an extension cord. Aside from bringing zero emissions to the jobsite, the all-electric pump and mixer combination removes a litany of equipment that all come with consumption costs.

Save on Costs

- No hydraulic oil

- No fuel (diesel, gasoline, propane)

- No oil filters

- No fuel filters

- No hydraulic filters

Electric Efficiency

The machine itself features a double drum mix system—much like interlocked fingers being pulled apart, explains Downs. “That's basically what our mixer does to the material. It gives it a shear which gives it a better mix,” he says. Reportedly, this process gets the job done quickly, capable of mixing at an efficient 2.5 minutes and pumping at presets of 10, 20, and 30 gallons a minute.

The FloorMate80 is a floor-by-floor basis, meaning one floor at a time due to the limitations of the length of the standard rotor-stator and the motors required to turn it. Going electric, Strong Manufacturing was able to increase the electric motor size which gave the torque needed to turn over a full-length rotor/stator. “What this does for the customer is gives them more pressure of the rotor/stator. This is what you need to push the material further such as horizontal and vertical,” says Downs. The FloorMate80E was designed to fit through standard doorways and through elevator shafts. While compact, however, the output pressure can send the slurry up 10 floors versus the traditional one.

“This becomes profitable because, to do those heights, a standard machine may run you in the $70k+ range—this unit comes in less than half that cost,” he says.

As strange as it sounds to say, it’s basically an eco-friendly mixer and not only because of the loss of emissions. While it’s not replacing the larger pumps, using the FloorMate80E in the right situation can save transport costs as well. “If you have a small job, you don't need to pull your big pump out. You can put this in a bed of a truck, put it on a load trailer, and roll it out there.”