Finding rebars inside concrete is vital for contractors, drillers, and construction engineers. Detecting the rebars’ position, including depth, is vital for many reasons; very often, there is the need to drill a hole in concrete without hitting the rebar, or you simply want to make sure that rebars exist, count their number and assess their condition. Measuring rebars is also performed for static calculations and to detect corrosion problems and damages.

Detection can be tricky, especially when you have multiple layers of rebars, young concrete or other elements inside. There are several methods available in the market each with its own pros and cons.

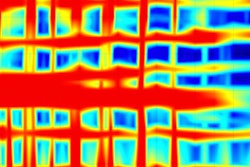

- Eddy Current (EC) is a method using magnetic fields for detecting and measuring metallic objects. Transmitting coils in a probe are charged by current and thus generate a primary magnetic field. On the surface of metallic objects within the magnetic field, eddy currents are induced, which produce a secondary magnetic field in the opposite direction. The resulting change of voltage in the receiving coils can be utilized for measurement.

- On the other hand, Ground Penetrating Radar (GPR) sends high-frequency electromagnetic waves down to the subsurface. The GPR calculates the time needed for a wave to travel down to a target and get back to the unit. This two-way traveltime gives the user a precise picture of the concrete subsurface, of foreign elements, like rebars and pipes. It is important to mention, that GPR compared to EC can detect both metallic and non-metallic targets.

- Digital Radiography (DR) sends a beam of X-ray to the surface and this radiation passes through the concrete and reaches a detector on the other side of the concrete. The detector calculates the radiation received based on the thickness and the density of the materials it had passed through and the user receives a picture on the screen with different shades of grey.

Eddy current method is used in non-destructive testing for detecting and measuring rebars within the concrete.Screening Eagle Technologies

Eddy current method is used in non-destructive testing for detecting and measuring rebars within the concrete.Screening Eagle Technologies

How Do These Methods Compare?

Since there is no perfect solution, it is always advisable to apply more than a method on the field for best results. However, if you are on a limited budget and you must go with only one method, it seems that GPR may be a solution that fills most gaps. As you can see from the table below, GPR is good in almost everything apart from sizing bars. If you absolutely need to calculate the diameter of a rebar, then either the EC or DR would work for you. GPR is superior in terms of depth penetration, tomographic views of the subsurface and can map almost any target.

| Methodology | Eddy Current | Ground Penetrating Radar | Digital Radiography |

| Good for Young Concrete | ✔ | X | ✔ |

| Single Layer Rebar | ✔ | ✔ | ✔ |

| Double Layer Rebar | X | ✔ | X |

| Can Size Rebar | ✔ | X | ✔ |

| Depth Penetration | Low (10-20 cm) | High (appr. 80 cm) | Low (30 cm max) |

| Can Scan From a Single Side | ✔ | ✔ | X |

| Metallic & Non-Metallic Targets | X | ✔ | ✔ |

| Data Collection Speed | Good | Good | Medium |

| Tomography of Subsurface | X | ✔ | ✔ |

| Voids Detection | X | ✔ | ✔ |

| No Need for a Safety License | ✔ | ✔ | X |

| Cost of Purchase | $ | $$ | $$$$$ |

| Cost of Maintenance | $ | $$ | $$$$$ |

| Cost of Certification | $ | $$ | $$$$$ |

| Training Needed | $ | $$ | $$$$$ |

The Proceq GP8800 was designed for congested rebar configurations, areas close to walls and underneath pipes, and irregular and curved surfaces like this rounded column.Screening Eagle Technologies

The Proceq GP8800 was designed for congested rebar configurations, areas close to walls and underneath pipes, and irregular and curved surfaces like this rounded column.Screening Eagle Technologies

But Which GPR?

There are many GPR units in the market that fit different needs. Screening Eagle Technologies offers hardware technology along with powerful and very easy-to-use software. Under this offering, a professional can select from three different units based on his inspection needs. The Proceq GP8800 is a handy unit, ideal for small and congested areas and for curved surfaces. Rebar detection inside piles is almost impossible for larger-sized GPR, a more compact model should be able to better collect data along the pile.

The GP8000, is a four-wheel GPR that has wider range of applications and can be used for longer profiles of rebar detection. Its ergonomics make it ideal for tunnel and bridges rebar scanning. Both GP8800 and GP8000 are single antenna systems, meaning they have only one source of wave transmission.

A different device compared to single antenna GPR systems is an array GPR. This term describes a system that carries multiple antennas for faster data acquisition and wider area coverage with a single pass. The GP8100 is the latest addition to our GPR series and comes with six antennas built-in. This unique design offers the user fast detection of rebars, without the need of multiple passes or 3D grid data collection and very dense and accurate GPR data. The GP8100 is ideal for rebar detection of large areas in buildings or bridge decks and a great tool for all concrete and drilling professionals who want a tool that will help them with their day-to-day work.

About the author

Michael Arvanitis holds a PhD in Geophysics. For the last twenty years he has worked as a GPR specialist holding different roles, currently being the Head of Global GPR Strategy and Marketing for Screening Eagle Technologies.

![Strux Macrofibers 58c9b97fd4aaf[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/08/strux-macrofibers58c9b97fd4aaf1.cNEEIfY9kp.png?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)