Content Sponsored by National Flooring Equipment

If you’ve heard of National Flooring Equipment before, chances are you’ve heard of our 5700 Ride-On Scraper. One of our most popular products, the 5700DL is a 2,700-pound machine that is narrow enough to fit through a doorway, yet fast enough to make quick work in commercial spaces; this rider is a workhorse.

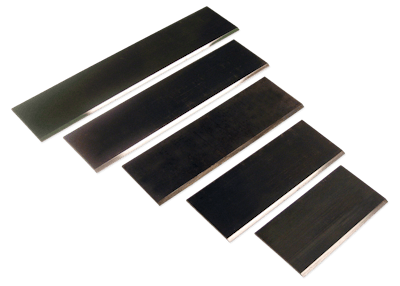

When it comes to choosing which blade or shank to put on the front of your 5700DL, or any other Ride-On Scraper for that matter, National offers 60+ tooling options. We take pride in this wide selection because we know that there isn’t a one-size-fits-all solution – this many pieces of tooling gives contractors options and ensures they can take on any job with confidence. Self-scoring blades for carpet and soft materials, bevel-down blades for wood subfloors, 4” tall wings for extra thick material, 1-inch blades for re-scrape, straight shanks for pavers, carbide-tipped angle shanks for ceramic, and so much more.

The material being removed, square footage, type of subfloor and specific machine all have a huge impact on tooling choice. Here is some information to get you started in sorting through the selection as well as why some of our most popular tooling stands out as the contractors’ choice.

Performance is Key

It feels counter-intuitive that an 8” wide blade is one of our best sellers. Wouldn’t a wider blade be more productive and get the job done faster? Not necessarily. An important factor in successful removal is finding the sweet spot where you aren’t sacrificing head pressure (which happens as wider blades are used) but optimizing productivity (using the widest blade you can, while still staying in the work).

Using a blade that is too long or wide during floor removal can slow down production. Concrete will never be completely flat — the aggregate used in the material will cause some undulations. As a result, using a longer blade against concrete means contractors must move very slowly to ensure they only remove the covering or adhesive, leaving the concrete intact. Take this comparison — if a contractor is using a longer 14-inch blade on concrete, they might have to move so slowly that they can only remove ten ft. of a material a minute, but if they swapped to a 10-inch blade in the same application, they might be able to remove 100 ft. of material a minute.

It's also important to consider while thinner blades are the cheaper option, they are designed for smaller jobs and walk-behind scrapers. Because of this, they are likely to wear down quickly on a larger machine or when being used on a tougher application. As it gets dull, operators can increase the angle of the tool to remove material, but this can cause the metal to bend, making work harder or stopping it completely.

Contractors might not always know what the job will require, and should consider having a toolkit of multiple blades on site. They can start with one blade and if removal begins to slow or the blade becomes blunt quickly, use another blade from their toolbox until they find the right tool for the job.

Bevel Up or Down?

Our self-scoring blades have a variety of options to consider, one of which is bevel up or bevel down. A blade with the bevel up — where you can see the angle of the blade from above — is best for removing flooring from concrete. A blade with the bevel down — where the bevel is underneath and cannot be seen — is best for removing a covering from wood. It is often easier to remember it as bevel up blades are for downstairs, and bevel down blades are for upstairs.

When removing a covering or adhesive from concrete, using a bevel up blade at a higher angle creates more pressure to separate material from the substrate. However, if you used the same blade on a wooden substrate, that pressure would dig into the wood, destroying the surface. Instead, having the bevel on the bottom allows the tool to glide over the wood.

To learn more about National’s tooling offering, you can browse the offering on our website, visit our YouTube page for videos, or always feel free to give us a call (800-245-0267) with your questions. Reach out to learn more about our upcoming training opportunities.

![Fcp Racatac Chair 10893876[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/10/fcp-racatac-chair-108938761.10l0At5WXv.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Fcp Racatac Chair 10893876[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/10/fcp-racatac-chair-108938761.10l0At5WXv.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)