"If you think about it, the current compression fracture testing, the standard actually is over 100 years old."

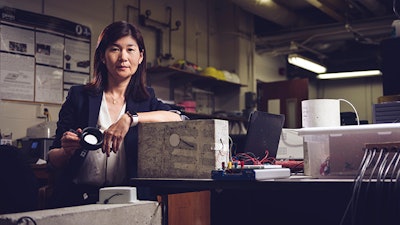

That's Dr. Luna Lu, Purdue’s American Concrete Pavement Association Professor of Civil Engineering and founder of WaveLogix. She continues, "We're using a very old technology to try to solve the current problem. Concrete Contractor spoke with Lu back in 2021 about her research in concrete.

Lu also is the ACPA Professor at the Lyles School of Civil Engineering with a courtesy appointment in materials engineering. She is the founding director of the Center for Intelligent Infrastructure at Purdue University. Lu invented the technology that WaveLogix is commercializing, having disclosed it to the Purdue Research Foundation Office of Technology Commercialization.

Back then, the goal was to address problems within the concrete infrastructure while harnessing artificial intelligence. That goal has not changed.

In 2017, the Indiana Department of Transportation (INDOT) was looking to reduce the premature failure of roads and bridges while limiting traffic closure times and commissioned Dr. Lu and her lab at Purdue University’s top-ranked Lyles School of Civil Engineering to find a solution. Four years later, following a successful R&D program and overwhelmingly positive feedback, WaveLogix and the Rebel concrete strength sensor system was formed.

The system was recognized in TIME's Best Inventions of 2023. Previously, the Rebel brand of concrete strength sensors was named a 2021 American Society of Civil Engineers GameChanger. The scientific paper also received the 2022 Alfred Noble Prize from the American Society of Civil Engineers.

The entry for TIME describes the WaveLogix Rebel Concrete Strength Sensor as follows.

Measuring the strength of concrete in highways and bridges has traditionally entailed “heavy equipment, extensive labor, and considerable uncertainty,” says Luna Lu, an associate dean and engineering professor at Purdue University who started WaveLogix, the company that makes Rebel Concrete Strength Sensors. The sensors, which are installed on a stretch of road before concrete is actually poured, transmit real-time data about the material directly to engineers’ smartphones, allowing them to ascertain when new construction is strong enough to handle cars or when to shut down a highway for repairs. Earlier this year, the sensors were added to highways in Texas and Indiana, with more states coming soon.

While surprised at the recognition, Lu understands why it earned its spot on the list. She sees it as a disruptive product that has the potential to replace traditional cylinder testing and making great impact in the quality and maintenance of concrete, construction, and scheduling costs.

"This is a very different technology compared to what's in the market," Lu says. "I'm proud what we have done in the past four or five years."

Product launch of the Rebel Concrete Strength Sensor system is scheduled for December 8, 2023.  The Rebel Concrete Sensor System by WaveLogixWaveLogix

The Rebel Concrete Sensor System by WaveLogixWaveLogix

Sensing Concrete

Being able to better understand what's happening within a concrete slab can be a boon to contractors, potentially cutting days off the job should the concrete be ready early. In general terms, there are two ways (or types) of sensor technologies to provide a look at what's happening within the concrete. For one, maturity sensors measure temperature and correlate it with time. That data is calibrated with the specific concrete mix used and an assumed real-time strength can be provided. Using historical data, 7, 14, 28-day strengths can be predicted.

Using a fundamentally different tactic, WaveLogix has developed a proprietary IoT sensing and data analytics platform for infrastructure testing and monitoring for the public infrastructure, vertical and other commercial construction and precast concrete markets. Its impedance-based sensing technology provides real-time, in-place concrete strength without the need for any pre-established maturity-curve or index, enabling construction engineers to make accurate data-driven decisions with respect to materials selection, construction schedules, budgets, and allocation of other critical resources.

"We send an acoustic wave in the concrete. By deciphering the wave propagation you understand the mechanical properties, in this case, elastic modulus of the concrete," explains Dr. Lu.

She says that this allows contractors to look at the true mechanical property - the mechanical fingerprint of the structures within the material. The technology behind the Rebel system then utilizes a machine learning algorithm to analyze the modulus data and determine the concrete's strength. "The biggest difference between our sensor and the maturity sensor," she says, "is our sensor directly measures mechanical property by using mechanical vibration and wave propagation to measure the resonance of the concrete."

The sensor device placed within concrete includes a cable to attach a data logger. The sensor itself is passive with its battery recharged when connected with a data logger. This allows contractors to check the concrete not only at 7 days but three years later. Lu says the lithium-ion battery should currently last 30 days but are working on getting to 60 days to accommodate California's need of 56-day acceptance.

Ultimately, the data WaveLogix will collect from thousands of construction projects and structures across the country will enable it to not only assess the current condition of bridges, roadways and other structures but also predict their future stability.

WaveLogix holds a license to market the Rebel system to the concrete industry. Purdue University owns the patent with partnership of the Indiana Department of Transportation. They've collaborated with DOTs around the country, from California, Texas, North Dakota, along with others for research and development.

"The benefits of this technology is really three features," says Dr. Lu. "One is direct mechanical measurement and the no need for calibration. Number two is it is very user friendly. You can get information very quickly using your mobile phone. And the third, is prediction of strength development.

For instance, in four hours [the Rebel system] can predict 3, 7, and 28-day strength because we have an AI algorithm. We have tested that with projects in Indiana, Tennessee, and Texas. I think that is very powerful for quality control, quality assurance. So, you can find out if there's a problem when your concrete is still wet - and it's easier to fix."

What Else In The Top 200?

Many products on the list aren't related to construction. In fact, "construction" isn't even a category. The Wavelogix Rebel Concrete Strength Sensor was listed in the Experimental section along with products like a Whiter Paint from Professor Xiulin Ruan (also from Purdue University), an extremely clever new way to provide GPS coordinates using muon particles from Professor Hiroyuki Tanaka (University of Tokyo), as well as a process that converts lithium carbonate into lithium metal from Li-Metal co-founder Maciej Jastrzebski.

Additional categories include Sustainability, Transportation, Robotics, and (in a surprise to absolutely no one) AI.

The full list can be seen at The 200 Best Inventions of 2023.