Contractors attending CONEXPO-CON/AGG 2017 not only have the opportunity to see the latest in construction equipment and technology but they also have the chance to attend over 140 educational sessions and seminars during show week. The educational sessions are grouped into 10 tracks including:

- Aggregates

- Asphalt

- Concrete

- Cranes, rigging and aerial lifts

- Earthmoving and site development

- Equipment management and maintenance

- Management best practices

- Workforce development

- Safety and regulations

- Technology

Sessions start Tuesday March 7 and run through Friday March 10.

Here is a sampling of education sessions offered during the show. For a complete list and in-depth descriptions of all the education sessions go to http://www.conexpoconagg.com/education.

Aggregates

Maximizing Screen Efficiency #T21

Tuesday March 7, 11:00 a.m.–12:30 p.m.

This session will give a comprehensive overview of an effective screening operation. It will discuss the appropriate application of various types of screens, how to measure the effectiveness, and how to evaluate the condition of the screen and structure. Attendees will come away having learned how to choose a screen for each application and how to measure screen efficiency and make changes to improve results.

How to Control Dust #TH21

Thursday March 9, 11:00 a.m.–12:30 p.m.

This session shows how to develop a dust control plan designed to comply with regulation without sacrificing productivity. By treating dust control as a problem of process control rather than a regulatory issue, plants can employ low-cost controls first to reduce reliance on more expensive measures.

Crusher Maintenance: Best Practices #TH41

Thursday March 9, 3:00-4:00 p.m.

This session will present the three types of maintenance (preventative, predictive and reactive) as they apply to crushing equipment. Attendees will learn the “do’s and don’ts” of crusher maintenance and will come away with the top 10 best practices.

Asphalt

Machine Control Technology in Paving and Milling #T22

Tuesday March 7, 11:00 a.m.–12:30 p.m.

As the demands on our infrastructure increase, it is critical for contractors to adopt technology to maximize quality and smoothness while minimizing construction costs and the time required to complete projects. Learning objectives for this session including understanding 2D vs 3D machine control and the benefits of both, understanding limitations of machine control and how machine control can increase producitivty.

New Technologies in Asphalt Paving #W11

Wednesday March 8, 9:30-10:30 a.m.

Focusing on Infrared (IR) Bar and Intelligent Compaction, this session aims to show attendees how real contractors are using these two technologies to help achieve consistent quality pavements and how contractors can apply these technologies to their operations.

Shingle Recycling in Asphalt Mixtures: Issues and Opportunities #TH22

Thursday March 9, 11:00 a.m.–12:30 p.m.

Attendees at this session will learn how to evaluate recycled asphalt shingles (RAS) material properties and how to properly use recycled material so failures won’t occur. The session will also cover binders and additives used for RAS and plant operations required to produce quality RAS mixtures.

Best Practices for Asphalt Compaction #F32

Friday March 10, 1:00-2:30 p.m.

This session will cover the four forces of compaction and how they are applied by various types of rollers. Attendees will learn how to utilize communication and consistency to balance laydown and compaction to achieve quality pavements.

Concrete

Opportunities and Threats for Concrete in the Low/Mid-Rise Buildings Market #T33

Tuesday March 7, 1:00-2:30 p.m.

This presentation will outline the National Ready Mixed Concrete Association’s (NRMCA’s) program for reversing concrete’s losses in the low- to mid-rise building segment. Detailed strategies including communications, direct project promotion and advocacy will be presented. The session will include an interactive discussion on how concrete producers and state affiliates can leverage their promotion activities to help recapture this key market segment for concrete.

Supplementary Cementing Materials for Use in Concrete #W12

Wednesday March 8, 9:30-10:30 a.m.

Explore the use of supplementary cementing materials (SCMs) and their impact on durability, workability, economy and sustainability of concrete. This session provides a comprehensive overview on the most common SCMs used in concrete construction and covers topics including the production process, physical and chemical properties and SCMs effects on both the fresh and hardened properties of concrete.

Chemical Admixture Technology: The Pathway to More Sustainable Concrete #TH23

Thursday March 9, 11:00 a.m.-12:30 p.m.

This session will discuss the newest innovations in chemical admixture technology. Attendees will learn how the correct use of chemical admixtures can optimize concrete performance, admixture selection for producing self-consolidating concrete and some approaches to troubleshooting cement-admixture incompatibility.

Achieving the Perfect Pour #F49

Friday March 10, 3:00-4:00 p.m.

This session will focus on how the ready mixed provider, concrete contractor and concrete pumper can work cooperatively in achieving a more productive, safer and profitable pour. Learning objectives will include how to coordinate and lead teammates to success and how to duplicate, refine and improve your concrete placement team for future projects.

Cranes, Rigging & Aerial Lifts

Quality Crane Inspection: What is That? #T34

Tuesday March 7, 1:00-2:30 p.m.

This session will cover when cranes are required to be inspected, who can inspect them, what qualifies a person to be a crane inspector, and how to know if you received a quality crane inspection. Attendees will learn about inspector training, experience, certification, membership affiliation with an Inspector Association and inspector insurance requirements.

AWP: Working Safely at Heights #W34

Wednesday March 8, 1:00-2:30 p.m.

This session will be a review of best practices for working at heights and options for improving jobsite safety. It will also cover the importance of training and training options available.

The Case for Cranes and Telematics: Specialized Circumstances & Concerns #TH13

Thursday March 9, 9:30-10:30 a.m.

Telematic data systems can help reduce costs, but important differences exist in the significance of data collected on ground equipment and the data from cranes. This session’s panelists will discuss these differences and challenges and share how telematic management systems assist their organizations in lowering costs using data fields specific to cranes.

Earthmoving & Site Development

Recycling to Increase Profitability: For the Small- to Medium-size Site and Demolition Contractors #T15

Tuesday March 7, 9:30-10:30 a.m.

This session will show how contractors have successfully utilized jobsite impact crushing to gain a competitive edge and increase profitability. Attendees will hear about removing concrete curbs, footing, slabs and asphalt paving, and crushing onsite for a third of the cost of hauling it away as well as discover how recycling affects bidding and profitability.

The Future is Now! Move More Dirt at a Lower Cost Using Machine Control #W25

Wednesday March 8, 11:00 a.m.-12:30 p.m.

This session will discuss efficiency opportunities in today’s earthmoving process and what options contractors have including the benefits of 2D and indicate systems, 3D systems, Masted Systems and Integrated Grade Control Systems.

Machine Control for Site Prep #TH34

Thursday March 9, 1:00-2:30 p.m.

Hear from a panel of industry experts how this piece of equipment can provide value today and beyond. The session will cover when to invest in machine control technology, current best practices for utilizing machine control technology to its full capacity and what excavating equipment machine control fits best.

Equipment Management & Maintenance

Using Technology to Build a World Class Maintenance Program #T46

Tuesday March 7, 3:00-4:00 p.m.

This session will show you how to develop more effective maintenance programs, reduce unplanned repairs and give operators the opportunity to positively impact your maintenance program. It will also cover how to mitigate risk with condition monitoring.

The Future of Equipment Management: Changing Opportunities and Challenges #TH15

Thursday March 9, 9:30-10:30 a.m.

The role of an equipment fleet manager has changed dramatically in recent years, and more changes are on the way. Hear a panel of experts in equipment fleet management describe and discuss the major changes they see in equipment management and how these changes will affect managers’ careers, both on a daily basis and with a long-term strategic outlook.

Driving Profitability with Maintenance Management Software and Mobile Technology #F45

Friday March 10, 3:00-4:00 p.m.

This session will explore financial and operational arguments for adopting specialized maintenance management software and how to leverage mobile technology in the process to enhance efficiency, data collection and reporting to alert, enlighten and inform the entire company. Attendees will learn which data points are crucial to improving operational performance and decision making and how to better manage documents and data to drive efficiency.

Management — Business Best Practices

Organization Agility and Adjusting to Change #T26

Tuesday March 7, 11:00 a.m.-12:30 p.m.

This session will examine the role of good change management in driving and sustaining complex, global change. In addition, it will address the role of scenario planning in agility, the need to reduce employee resistance to leaving the comfort of the current state and the power of foresight as an organizational strength.

Improving Project Success (and Profits) through Integrated Project Delivery #W26

Wednesday March 8, 11:00 a.m.-12:30 p.m.

Integrated Project Delivery (IPD) integrates everyone on a project team to harness the talents of every discipline to maximize success through all phases of design, manufacturing and construction. This session will discuss how IPD can help improve project success and maximize profits.

Optimizing Your Jobsite: Overcoming Skilled Labor Challenges with Machine Controls & Data Analytics #TH16

Thursday March 9, 9:30-10:30 a.m.

This interactive presentation will explore ways you can leverage the data coming from your machines, production environment and semi-automation of your jobsite to optimize results.

3 Paths to Profit: How to Leverage Project Planning for Better Results #F35

Friday March 10, 1:00-2:30 p.m.

Learn how to leverage critical planning and scheduling skills to boost the volume, value and velocity of work your organization delivers. The session will also explore why scheduling reliability is your most powerful financial improvement tool.

Management — Workforce Development

Solutions for Finding Skilled Labor #T27

Tuesday March 7, 11:00 a.m.-12:30 p.m.

This session will highlight multiple avenues available to contractors from staffing agencies to military recruitment, tech schools to associations.

The Upskilled Workforce: Strategies for Growth #W28

Wednesday March 8, 11:00 a.m.- 12:30 p.m.

The current workforce is expected to experience significant disruptions in job functions due to upcoming technology integrations. This session will dive into some of those “upskilling" requirements and how companies can help position and transition their employees. Learning objectives include: understanding current trends in technology driving change in skills, evaluation strategies for understanding your organization’s skills gaps, and implementing a successful transition to drive retention and growth.

Fifteen Must-have Productivity Apps #F36

Friday March 10, 1:00-2:30 p.m.

Learn about great apps that can make your life and work easier. This session will share the apps and show you exactly how to use them. Attendees will learn how to choose what apps work best for them and how to maximize the potential of apps to improve workflow.

Safety & Regulations

OSHA Compliance: How to Avoid Fines #T28

Tuesday March 7, 11;00 a.m.- 12:30 p.m.

This session will prepare participants for potential interaction with OSHA. Learn how to prepare for an inspection, how to address citations and fines, and what to expect in the future. Topics addressed include: recordkeeping and documentation review, employee interviews, the appeals process and potential for collateral litigation.

Coordinating Equipment, Trucks & Worker Movement in Work Zones #W29

Wednesday March 8, 11:00 a.m.- 12:30 p.m.

Based on more than a decade of government and industry research, this presentation includes step-by-step instructions to prevent worker “struck-by” incidents through the creation of Internal Traffic Control Plans (ITCPs). Topics covered include blind spot recognition, work zone access/egress and safe backing procedures.

Improving the Safety of Your Operators Through Technology #TH17

Thursday March 9, 9:30-10:30 a.m.

This session will address current methodologies to improve fleet safety on the road and at the jobsite. It will cover how to use analytical data as proof points to improve operator performance, best practices and how they change operator behavior, and emerging technologies that limit distractions and provide ROI.

Avoiding and Mitigating Defect Risks #TH38

Thursday March 9, 1:00-2:30 p.m.

Risk control professionals will share their expertise and strategies for recognizing, preventing and mitigating these potentially costly losses. Learning objectives include how to identify mitigation strategies to enhance quality construction and how evolving technologies impact construction risk.

Developing an Empowering Culture of Safety #TH49

Thursday March 9, 3:00-4:00 p.m.

This session will focus on your role and responsibilities in learning from safety situations, understanding the costs of safety and risks, combating apathy, and building your team’s buy-in.

Technology

The Next Generation Jobsite: Drones #T19

Tuesday March 7, 9:30-10:30 a.m.

The session will show participants how drones can be an important tool to the industry and major part of the equipment fleet. Attendees will learn how to select the right drone to meet specific applications, know proper regulations for the use of drones and understand what insurance coverage and liability issues apply to drones.

Extracting Big Results from Big Data, 3D Imaging & the Internet of Things: Heavy ROI for Heavy Equipment #T29

Tuesday March 7, 11:00 a.m.- 12:30 p.m.

Knowing what data you need and how to apply it for your organization presents an ongoing challenge. This session will cover practical ways to identify the most likely areas for ROI and then collect the right data.

Autonomous Machines: The Future is Now #W39

Wednesday March 8, 1:00-2:30 p.m.

This presentation will preview semi-autonomous and autonomous technology, its current state among equipment manufacturers and inherent issues for owners and workers.

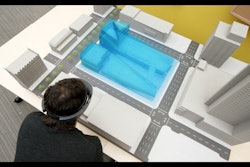

The Future of Making Things: Technology in Construction #TH29

Thursday March 9, 1:00-2:30 p.m.

This session will take a look at key disruptions and transformation coming in the construction industry and how technologies can help you navigate these disruptions. It will also look at examples from around the world that have achieved meaningful business transformation through emerging technologies.

Heavy Hybrid Technology #F19

Friday March 10, 9:30-10:30 a.m.

In this session you will find out what’s new with hybrid technologies, when hybrids should be considered and for what applications, gain a better understanding of the advantages and disadvantages over the life of the machine, learn the ROI on hybrids over conventional, and market demand for this technology going forward.

![[VIDEO] Caterpillar Shows How Virtually Reality Can Improve Field Diagnostics](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/06/default.5764340cc06b3.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)