Like most manufacturers, Terex Utilities has used 3D CAD to design its products for years. However, the specialized software, hardware, and systems integration required for 3D made it painful, and difficult to use outside unit engineering.

Terex Utilities relied on 2D drawings with customers but understood the well-known benefits of 3D and wanted to extend it to their sales team. So they turned to Vertex Software and its cloud-based approach to 3D visualization to overcome the historical challenges of using 3D CAD beyond engineering.

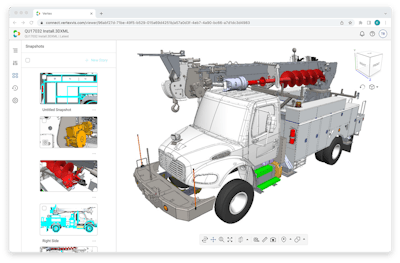

After partnering with Vertex Software in 2019, Terex brought its equipment drawings to life in 3D with Vertex Connect. As a result, its customers could now see what they were buying right before their eyes, a real-life visualization of their future truck. With Vertex Connect, Terex Utilities unleashed the potential of their 3D CAD investments, delighted customers and gained substantial time and cost efficiencies.

Terex Utilities a manufacturer of large machines such as aerial devices, digger derricks and auger tooling for the electric utility industry, builds those machines to order with unique design details specified by the customer.

Terex Utilities’ customers make a big investment when purchasing complex and specialized equipment. For this reason, Terex enables its customers to review equipment designs numerous times before assembly, to ensure they get exactly what they want. During the reviews, customers frequently provide feedback and suggest changes or additions to their equipment orders.

Vertex Software

Vertex Software

3D Drawings Reduce Confusion Compared To 2D

Like other manufacturers, Terex Utilities uses 3D CAD to design its products, but for years relied on 2D drawings in sales due to the complexity of creating 3D drawings. 2D drawings often made customer design reviews problematic, however. For example, from flat diagrams, customers couldn’t clearly understand how a truck would look when built. They couldn’t envision the space available in a truck bed or get a sense of how the real-life physical equipment would look and function.

“It was hard to truly visualize the equipment and specific placement and distance between components and features,” said Terex Utilities Project Lead Linh Le. "You want to see past the hidden lines."

Customers would often miss a design change they’d like to make. As a result, Terex engineers sometimes had to redesign and remake part of the equipment because a customer hadn’t noticed a critical design consideration for their application. That meant expensive rework, lost time and delivery delays.

“You can imagine waiting awhile for a truck, and then you can’t have it for a couple more weeks because now you’ve got to take it somewhere and get stuff moved and repaint it,” said Scott Lester, a Terex Utilities customer.

The sales team also lost time printing the 2D drawings for the customer to review. Printing could take hours. Sending PDF documents to customers put the printing load on the customer, which could delay and add frustration to the sales process.

Lucas Thompson, Terex Utilities Territory Sales Manager, remembers his many trips to office-supply stores, “I’d go print off 80 pages on ledger-size paper and take it to the customer.”

When the final product didn’t meet customer specifications, the problem was often directly tied to the complexity of the 2D drawings and customers’ inability to envision what the equipment would look like in real life. It became clear that Terex customers had difficulty understanding complex 2D CAD drawings created by trained engineers and drafters.

Terex Utilities wanted a way to present equipment design options to its customers in a simple, straightforward fashion. They also wanted a way for their entire company to communicate about product design, assembly, sales and service. They envisioned giving everyone a virtual window into engineering as if they were looking over the shoulder of a 3D CAD operator.

Vertex Software

Vertex Software

A 3D Experience

In 2019, Terex Utilities partnered with Vertex Software to deliver a 3D experience for their sales team and customers, and the value Vertex offered was evident from the beginning. Vertex Connect transformed its 2D process that often required printing and physical delivery into email delivery of a web link to a realistic, interactive 3D model that can be rotated and viewed from all angles.

"Vertex is great! It is great for us to have 3D for the first time in reviewing the final order and later as we operate the vehicle," said a Terex Utilities customer.

One big draw for Terex is that anyone can pull the 3D views up on any screen. Tablet, laptop, desktop, smartphone: it doesn’t matter. Customers, factory personnel, and supply chain partners get their product information, mark-ups, and approvals much faster with Vertex Connect. For Thompson, this eliminated his lengthy “print runs” to the office-supply store.

Vertex Software

Vertex Software

Improved Process, Error Rates Plummet

Thompson summed up the impact Vertex has had on him: “[Vertex Connect] improves the quality of the sales process and improves the quality of the final product because it helps the customers see the final product.”

He pointed out that repeat customers are thankful for Terex's investment in Vertex Connect.

Le attests to how the visualization surprises and delights customers, “It’s almost as if they’re on the truck before it’s even built,” said Le. “Customers are delighted, and the quality of the end build is better. No more reams of paper or dry rows of numbers. Instead, they see the lifelike truck on whatever screen they have in front of them.”

After Terex Utilities implemented Vertex Connect, error rates declined significantly. Now, nearly all produced trucks precisely match customer specifications.

"It cuts down any problems, issues, or confusions in the initial purchasing with us taking ownership of the truck. Vertex helps us get exactly what we want when they deliver the truck. It is now 99.99% correct for what we thought we were purchasing," said a Terex Utilities customer.

Cut Travel Costs

Another benefit of using Vertex Connect was that it cut down on travel allowing the design team more time to work on developing the customers products not travel.

“Over the last few months, we’ve had zero travel to customer sites — something that wouldn’t be possible without the capabilities available in Vertex,” said Kyle Wiesner, engineering manager. “Long-term, this change to our process stands to save countless dollars and time for our sales team while improving the experience for our customers.”

Another Win: Digital Twins for the Factory

Since adopting Vertex Connect, Terex Utilities has leveraged the 3D truck configurations created during the sales process in the factory for assembly instructions and build reporting. These 3D digital twin applications, operating on low-power computers and built on the Vertex 3D Platform, replace a paper-based, three-ring binder known as “the traveler” that follows each customer order along the assembly line.