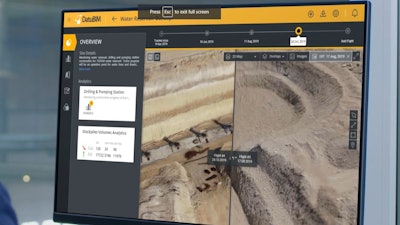

Datumate, a construction data analytics platform company, updated its automated, digital grade checking capabilities.

The DatuBIM Construction Data Analytics platform now transforms 2D designs into digital data model objects, calculates grade checking reports and further automates progress monitoring.

This entirely digital process significantly reduces work, prevents human error, saves professional resources, and ends the construction companies' dependence on several software tools to perform these frequent reports.

DatuBIM's new capabilities cut down office work for grade checking by roughly 70% on a typical elongated infrastructure project.

See how it works:

"Our customers are extremely excited about our new, automated grade checking. For them, it is an entirely new level of efficiency and control. And for us, it is an ample example of what we want to achieve with DatuBIM: making infrastructure construction better," says Jad Jarroush Datumate, founder and CTO. "DatuBIM's virtual 3D data objects derived from 2D plans and automated grade checking are a giant leap that brings our customers closer to BIM with 4D (schedule) and 5D (costs). Right now, we see that our customers, as the construction industry at large, need help in handling 3D. So our role is to make sure they reap all the benefits that 3D can offer."

Grade checking is frequent, time-intensive surveying of terrain changes to monitor construction work, track progress, ensure quality, and detect deviations in the layer buildup.

In infrastructure projects such as highway and railway embankments, surveyors measure hundreds and sometimes thousands of points several times a week on the jobsite. As points measured by the surveyor might not fall in place on existing layer design plans, further data manipulation by a civil engineer or CAD technician is required to analyze the data set and create grade checking reports, which construction foremen and supervisors can put into action.

DatuBIM now turns the traditional, manual grade checking into a fully digital and automated process, all done in a single platform, with fast turnaround and no additional office work.

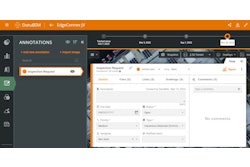

With the new digital grade checking capabilities, customers can upload all their 2D designs (horizontal alignment, vertical profile, and cross-sections) to DatuBIM. The platform automatically generates a 3D virtual design model as a digital data model object for comparison and analysis.

Datumate

Datumate

Comparing to either imported survey points or as-built 3D site models created by the platform, DatuBIM analyzes and delivers grade checking reports automatically on the desired area with a click of a button by the foremen, construction managers, or civil engineers.

While DatuBIM can automate and accelerate the entire process using data collection via drones and eliminating the need for manual surveying, construction companies may want to stay with their standard surveying practices.

Also for these companies, DatuBIM's automated grade checking will make the process exponentially faster, less labor-intensive, and less prone to mistakes. DatuBIM's game-changing technology saves companies valuable time and substantial money.

"Digital transformation is a journey. Our responsibility is to enable our customers to take the next step now, at whatever point they are. The large majority of infrastructure construction projects are still designed in 2D, but the surveying field data is 3D. Therefore companies are forced to perform tedious, manual work of data transformation for progress tracking and analysis. DatuBIM makes this a thing of the past and helps companies still designing in 2D to control their sites better and at the same time move their enterprises towards BIM, 4D, and 5D management." says Itay Segev, vice president of products and marketing. "To accelerate the adoption of digital construction, technology shouldn't break processes but improve them and bring companies closer towards BIM methodology. Our customers expect and want innovation, not disruption."

DatuBIM's automated grade checking brings additional benefits as it transforms previously siloed data to interactive and easily shared digital data that:

- Gives access to progress history

- Is securely stored

- Allows for analytics on past phases

- Can be part of cut-fill and progress reports

- Is available for completion-to-design reports