Monitoring systems can help improve the return on investment of today’s excavators. For example, Komatsu’s standard KOMTRAX system provides vehicle operation information to help manage fleet idle time and maximize equipment use. With the system alerts, downtime can be minimized if an issue arises with the health of a machine.

Bruce Boebel, senior product manager, Tracked Products, Komatsu America Corp., notes that improvements in the Komatsu Dash 10 series excavator monitors were driven by the need to provide easier ways to service machines. “These monitors now include built-in, advanced, easy-to-use onboard diagnostic capability,” he points out. “Some OEMs require a laptop computer for advanced troubleshooting. Komatsu opted to incorporate vehicle diagnostics into the machine itself.”

Doosan excavators are also equipped with an easy to read LCD display panel for viewing critical machine data and configuring attachments. The manufacturer also has a standard fleet management system that allows customers and dealers to see/review critical machine information, monitor downtime and so forth.

Most of John Deere’s 22 excavator models come equipped with JDLink, a remote monitoring systems that passes machine “vitals” — including fuel consumption, usage, and productivity details — to owners, dealers and fleet managers.

Caterpillar’s Product Link technology also transmits information such as machine health, location, hours of use and fuel consumption back to customers and Cat dealers. This technology enables customers and dealers to proactively work together in managing equipment.

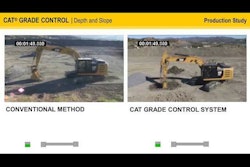

In addition, the E Series excavators are equipped with Cat Grade Control Depth & Slope technology. “The factory-installed system provides visual guidance of the jobsite plan to the operator without the use of traditional grade stakes, which saves time and money,” says Ken Gray, Caterpillar global excavator product manager.

As one OEM states, “Excavators are a mature product and operators likely won’t see huge changes in the way they look or operate, at least on the surface.” New technologies, however, will continually be adapted to these workhorses to improve their performance and cost benefits to end users.