Carlisle TyrFil this year celebrates the 50th anniversary of its TyrFil brand, known as the world's first polyurethane tire fill material intended to flatproof tires. During the past five decades, TyrFil has become the industry standard in tire fill flatproofing and is utilized in over 65 countries. The company is proud to be the proven supplier to the world's top equipment manufacturers and has the most OEM tire fill approvals in the industry.

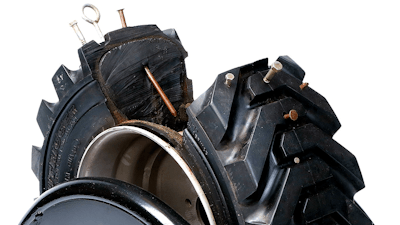

Rendering tires virtually "flat free" on the job, TyrFil enables off-the-road (OTR) equipment to glide over typical work site debris, such as sharp rocks, nails, glass, and rebar, that would otherwise leave machinery vulnerable to dangerous and costly tire punctures.

TyrFil can be pumped into any pneumatic tire to replace all of the air with a resilient, synthetic elastomer core that eliminates flats and offers super shock absorption, ensuring a smoother ride for equipment operators, while vastly reducing tire wear, tear, and denigration.Carlisle

TyrFil can be pumped into any pneumatic tire to replace all of the air with a resilient, synthetic elastomer core that eliminates flats and offers super shock absorption, ensuring a smoother ride for equipment operators, while vastly reducing tire wear, tear, and denigration.Carlisle

TyrFil can be pumped into any pneumatic tire to replace all of the air with a resilient, synthetic elastomer core that eliminates flats and offers super shock absorption, ensuring a smoother ride for equipment operators, while vastly reducing tire wear, tear and denigration. Despite cuts and punctures, filled tires will keep performing, increasing productivity and eliminating costly downtime for field operators.

TyrFil is flatproofing technology for the construction, mining, materials handling, equipment rental, waste management, military and agricultural industries. TyrFil has evolved from one, general-purpose formula to a comprehensive product portfolio to meet industry demands. Now, TyrFil comes in a variety of durometers so the type of fill can closely fit the application, from a softer fill for comfort and deflection, to a harder fill for slow-moving equipment with high pressure requirements.

"TyrFil has proudly led the tire flatproofing market for 50 years, offering operators and commercial and industrial fleet managers a host of advantages related to shock resistance and cushioning, wear, abrasion, durability, traction and cost," says Matt Pearson, vice president of global sales for Carlisle TyrFil. "The brand has a long legacy as the pioneer in tire flatproofing and processing equipment technologies and has laid the foundation for all future polyurethane fill innovation, based on science, customer service and scalability."

Since 1971, Carlisle's facilities have processed more than 1 billion lbs. The Berea, Ohio manufacturing facility has been issued a certificate of registration by Perry Johnson Registrars, Inc. for conformance to ISO standards.

During the past two decades, Carlisle TyrFil has introduced next generation technology that significantly reduces the usage of oil, petrochemicals, toxic metals and other environmentally harmful compounds. In 2021, Carlisle TyrFil introduced the latest extension to its recycling technology line-up to further drive adoption of sustainable manufacturing practices within the OTR tire industry.

The new patented AutoFil-GenII processing pump can mix virgin tire fill with rubber crumb, PU grind or both rubber crumb/PU grind, while delivering maximum processing speeds and an enhanced visual data interface through a monitor with an improved HMI touchscreen capability.

"TyrFil's advanced AutoFil-GenII strengthens Carlisle's commitment to superior flatproofing performance, sustainability, and materials handling best practices," says Pearson. "For the past 50 years, the TyrFil brand has made eco-supportive product development a top and long-term strategic business priority. The AutoFil-GenII is an integral new development in this continued heritage and commitment to putting environmental protection front and center to our business."