Knowing the type of aggregate in the concrete or asphalt to be cut influences the performance and selection of diamond blades and drill bits. Aggregate, the stone, gravel and sand used in concrete and asphalt, varies by geographic region and often, even within a specific location.

The hardness of a mineral relates to its resistance from abrasion, and is defined in terms of Mohs hardness scale. This scale designates a value ranging from 1 to 10 (with .5 increments) for each mineral, with 1 being the softest and 10 being the hardest. The following minerals are used as standards: 1 Talc, 2 Gypsum, 3 Calcite (soft limestone), 4 Fluorite, 5 Apatite, 6 Feldspar (some river rock, some type of granite), 7 Quartz (some river rock, some types of granite, basalt, quartz, trap rock), 8 Topaz, 9 Corundum (flint, chert, trap rock, basalt), and 10 Diamond. A mineral of a given hardness can scratch all minerals of a lesser hardness but can scratch no minerals of a greater hardness.

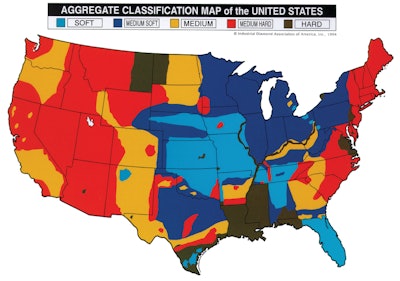

This map will give you a general idea of what type of aggregate to expect in each geographic area from a soft, abrasive aggregate, like talc, to a hard and non-abrasive aggregate, like flint or chert, and the various medium to medium-hard levels and abrasive qualities in between. It shows the aggregate and its hardness that is likely to be found within each state, but should be used only as a general guide in blade selection for sawing and drilling. Understanding that aggregate size and type can vary significantly within a given area, it is generally true that aggregates are similar in certain geographical areas. This is primarily due to local availability of one particular type of material; however, an increasing amount of aggregate is being shipped in from different states across the U.S. This aggregate map shown is a guide to the most common aggregate in the area.

Having determined the aggregate type, the other factors that need to be considered in selecting the diamond blade for sawing and drilling concrete include the size of the aggregate and the age of the concrete. Concrete has sand, either natural or quarried, plus some type of reinforcement, typically steel rebar. These aspects are important to consider as even slight changes in any of these elements may influence both the cutting speed and the longevity of the diamond blade.

Lastly, both the equipment to be used and the technique of the machine operator must be taken into consideration. The age/condition, power rating and recommended RPM for the equipment should match the blade in the same way that the blade chosen must be a good match for the aggregate encountered. Not surprisingly, cutting techniques change with experience and knowing how to change cutting approaches for different types of aggregate.