In airless paint equipment, the traffic paint is drawn from a paint tank, tote or bucket into a high-pressure pump which delivers the paint through a filter to the paint gun. The paint is pushed through a small tip in the paint gun at high pressure usually ranging from 1,000-3,000 psi. The finished product is a crisp-edged, clean-looking line. Always use extreme caution when working with airless paint systems, since the paint coming out of the gun is under high pressure and can cause serious injuries.

Airless tips

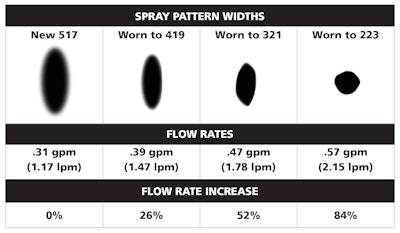

The airless paint system may use a reversible paint tip that can be turned 180 degrees to extract an obstruction without disassembling the paint gun. Choosing the paint tip is critical in a good paint application. Consult with a paint distributor for information specific to their product selections.

- Graco road striping tips, for example, are yellow in color and have a three digit number stamped on it (see photo).

- Any series of letters are Graco’s identification numbers which differentiate various tip styles. The second three digits (621) represent the actual tip size (fan width and orifice).

- The number six, when doubled, indicates the approximate fan width when spraying 12 in. from the surface. The fan width on a 621 tip is approximately 12-14 in. (Graco tips are tested 12 in. from the surface using water sprayed at 2000 psi. Different materials and spraying pressures may slightly change the width of your actual fan pattern.)

- The last two digits (21) indicate that

Titan's first number is not doubled: 4 in this example is the actual width of the 4-in. fan pattern (6 in. from the surface). The last two digits (17) indicate the orifice size in thousands of an inch (.017).

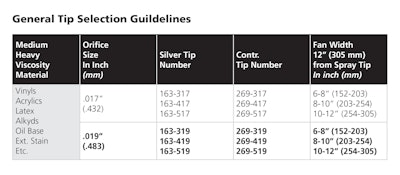

Titan's first number is not doubled: 4 in this example is the actual width of the 4-in. fan pattern (6 in. from the surface). The last two digits (17) indicate the orifice size in thousands of an inch (.017). - Contractor flat tips are not reversible and must be removed for cleaning. The numbering system is similar to that of the reversible tips in that the first three numbers (163 in the photo) are the type of tip. The number 4 represents the spray fin width and the 15 indicates an orifice size of .015 inch.

Titan, manufacturer of the PowrLiner Series of pavement marking equipment, takes a slightly different approach to its tip-size designation. Where Graco doubles the first number of the tip size to indicate fan width, Titan does not. The 4 in this example is the actual width of the 4-in. fan pattern (6 inches from the surface). The last two digits (17 in this example) indicate the Flat Spray tip No. 163-415. The first three numbers (163) are the type of tip. The number 4 represents the spray fan width and the 15 indicates an orifice size of .015 inch.

Flat Spray tip No. 163-415. The first three numbers (163) are the type of tip. The number 4 represents the spray fan width and the 15 indicates an orifice size of .015 inch.

General Tip Selection Guidelines

This is a general guideline to help you select a tip. These guidelines are the same whether you are using long-line striping equipment or walk-behind striping equipment on parking lots or smaller road or intersection projects. Your equipment manufacturer or distributor should be your final source of information. They can recommend a tip based on their experience with an application like yours, or they can help you conduct a test.

- General tip recommendation: The following flat tips give good results with the most commonly used coatings. For the best results spraying on flat surfaces, an 8-10 inch or 10-12-inch spray fan width is recommended.

- Determine the maximum flow rate of your spray system. Your spray system (sprayer or pump and power source) must be sized adequately to support the flow rate of the tip you select. If your pump is supporting more than one gun, add together the flow rate needed for each gun.

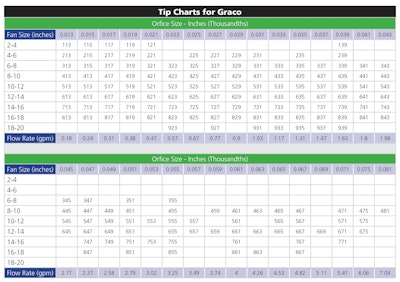

- Determine the required orifice size on the tip chart. If the total maximum flow rate(s) is compatible with your spray system, select the desired fan width and then order the tip number given in the adjacent column. As an example see the chart below.

In airless paint systems, the size of the pump and spray tip will determine the gallons of paint per minute (GPM) that can be applied by your paint system. The paint tip size works in conjunction with the paint pump pressure and speed of the machine to give you the desired line width and thickness.

Line marking airless spray tips should be designed for sharp distinct edges with an uneven spray coating coverage across the entire spray width. These tips may be described as heavy edge tips and can be used with any compatible airless striping sprayer.

Selecting the Proper Tip Size for your Application

The flow rates listed with each tip on the tip selection chart (See Graco Chart) are established with water at 2000 psi; paint flow rates will vary based on the viscosity of the material and with different pressures. Therefore the following process must be followed in order to identify the specific tip that will be required in order to apply the marking at the required width and thickness, at a specified speed of application device.

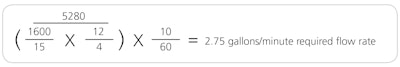

1. Determine the required paint flow rate.

This relates to the required rate of paint needed to flow through the paint tip at the desired speed in order to deliver the required line width and thickness. This can be determined by solving for the equation below.

Where “B” = Planned Width of marking in Inches

Where “C” = Planned Speed of Paint machine in Miles per Hour

For example:

Planned Paint Thickness = 15 mils

Planned Width of Marking = 4 inches

Planned Speed of Truck = 10 Miles per Hour

3. Perform a paint calibration test with the striping equipment to determine the thickness of the paint at the desired operating conditions.

Place the 163-451 paint tip into your spray gun and stripe a 4-inch line at 10 mph. it is best to set your paint pressures in the middle of your operating range, and run the test as close to painting conditions as possible (temperature, mixed paint). The test stripe should pass over a rigid clean metal paint. Immediately after the truck passes over the test plate use a comb gauge to measure the thickness of the paint. Your actual millage should be less than 15 mils, as paint is more viscous than water. For this example let’s assume your millage is 11 mils.

4. Calculate the efficiency number of the paint tip that you are using. To do this you would divide the actual millage by the theoretical millage. In this case:

11 ÷ 15 = .733

This would be the efficiency “number” of your paint and equipment during painting conditions.

5. Determine the paint tip that will be needed to give the required paint flow based on the efficiency number calculated in Step 4 above. This is done by dividing gallon-per-minute requirements by your efficiency number.

2.75 ÷ .733 = 3.751 gallons per minute adjusted flow rate

When you look at the standard Graco tip chart you will see that a 59 thousandths tip is needed for this application [highlight square?]

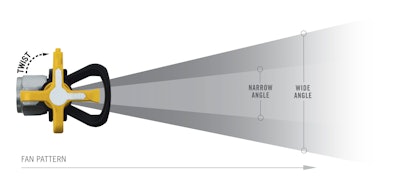

6. Perform a paint calibration test using the newly selected 163-459 tip according to Step 3 above. This step  Titan's TR2 reversible tip is the industry’s only dual spray tip, enabling contractors to switch to wide (10-in. to 12-in.) or narrow (4-in. to 6-in.) fan patterns with a twist.

Titan's TR2 reversible tip is the industry’s only dual spray tip, enabling contractors to switch to wide (10-in. to 12-in.) or narrow (4-in. to 6-in.) fan patterns with a twist.

Note 1: Remember to keep in mind that your high-pressure pump must have a sufficient rating to support the required flow rate of the maximum number of guns that will be operating at any one time at the planned speed of the paint application equipment.

Note 2: A software tool is available to perform these calculations regarding tip selection.

Information for this article was provided by Ennis-Flint, manufacturer of a broad variety of pavement marking materials including waterborne and solvent-based traffic paint, thermoplastic and preformed thermoplastic. For more information visit www.ennisflint.com.

Titan's TR2 Reversible Line-Striping Tip is a dual pray tip that enables an operator to spray wide or narrow fan patterns with the same tip.

Titan's TR2 Reversible Line-Striping Tip is a dual pray tip that enables an operator to spray wide or narrow fan patterns with the same tip.

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)