Asphalt pavements can account for a significant share of an owner or property manager’s facility assets. It’s the aim of these clients to preserve the value of their investments and maintain the property’s appearance in the most cost-effective way.

Investment in ongoing maintenance prevents deterioration and provides serviceable pavement condition over an expanded period of time. While ignoring maintenance of the pavement saves on upfront costs, it allows the asphalt to deteriorate rapidly, requiring earlier major rehabilitation expenses.

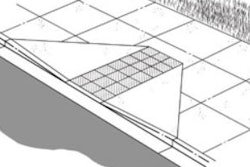

Periodic application of an effective sealcoat to asphalt pavement acts to reduce exposure of the pavement to the elements and slows the deterioration of surface properties. Their long-term success depends on their mix and application process.

In general, sealers are made of either a refined tar or an asphalt binder mixed with sand, water and additives such as drying agents. The success of the sealer depends heavily on the proportioning of its various components. The first thing to recognize is that there’s no such things as one-formula-fits-all. Each sealer should be designed individually to the unique characteristics of the binder and sand that influence the performance of the sealer.

The PCTC provides recommendations on the gradation of sand and the amount of sand to be used in the design of sealer. The amount of sand, commonly referred to as “sand loading” has been an issue in the industry for years. A PCTC field project generated valuable data in support of the sand loading issue for refined tar-based sealers. Field test sections were constructed with sand loadings of 3, 5 and 18 pounds. The sections were then monitored for their resistance to normal traffic loading wear. After four years of field monitoring, it was concluded that the sections with the 3- and 5-pound sand loadings significantly outlasted the sections with the 18-pound sand loading.

The 3-pound sand loading with and without topcoat maintained the best coating ability after two and three years of age. The 5lb sand loading sections also exhibited excellent durability after two and three years of age. The 18lb sand loading sections without topcoat completely wore off the pavement after three years and showed poor quality after two years. The 18lb sand loading sections with topcoat maintained a minimum coating ability after two and three years of age.

Based on this study, the PCTC strongly recommends that the sealer be designed for the unique characteristics of the binder and the sand that are being used on the job, and sealer designs with high sand loadings (above 5lbs) should not be accepted.

With the help of pavement maintenance contractors and sealcoat manufacturers, the property owner can achieve these goals, to keep the pavement looking good and extend its service life. With a little guidance on pavement performance, most owners and contractors will be able to make smart decisions.

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)