Use of hot box reclaimers, as discussed in a February Pavement Maintenance & Reconstruction article, offers contractors a number advantages, including improving the success rate of patches constructed late in the day.

"Without a reclaimer the mix you start the day with cools as you drive from job to job placing a little mix here and there, and your patch success rate suffers," says KM International's Kurt Schwartz, sales & marketing. "When you have a hot box reclaimer and you can get hot mix fresh at three in the afternoon you'll see your production and success rate go way up right away."

Other high-profit benefits of owning a hot box reclaimer are that they enable contractors to start the season early, extend a season a bit longer, and keep key workers employed through months when area asphalt plants shut down.

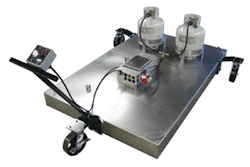

But contractors looking to use a hot box reclaimer to extend their season must stockpile virgin hot mix and prepare it for easy access and use during the winter. Here's one approach to organizing your stockpile.

- Place the asphalt in a manageable row 3- to 4-in. thick and roughly 2 ft. wide. Lightly compact the mix.

- Once the mix has cooled, stack the pieces for easy storage. Mix can be stored on a pallet or in a shed corner on the floor.

- Use paper or plastic between pieces of mix. This prevents the pieces from freezing together and makes it easier to move them during cold weather.

- As pieces are needed for a job simply place as many as you need into the hot box reclaimer which will heat them to a workable temperature.

Read "Hot Box Reclaimers" from the February issue of Pavement for more about the benefits of hot box reclaimers.