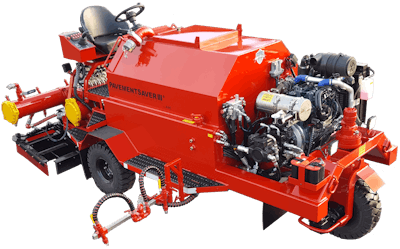

The features of the PavementSaver III include a Control Area Network and an Autonomous Rate Control System.

- 49-hp, turbocharged diesel engine Tier 4 Final compliant

- Heavy-duty squeegee assembly with hydraulic directional control

- Variable speed direct drive hydraulic agitated mixer

- Intuitive joystick controls

- Full three-wheel drive system

- Spray bar starts at 8-ft. and can extend to 12-ft.

- Pressure sensing technology keeps application rate consistent

- Various nozzle configurations, tips sizes and spray patterns available

Fill out the form below to request more information about Rayner PavementSaver III