Glass fiber reinforced concrete (GFRC) has a long history of use in building facades, and was originally developed for its superior performance in seismic zones. The decorative concrete industry embraced it not only for its strength, but the versatility it provides for creating texture, color and form otherwise impossible with traditional precast.

The basic principles of GFRC are simple. Typical mix designs use a cement rich blend, combining one part cement to one part graded, dry sand. With the addition of water, curing polymer and glass fiber for reinforcement, GFRC is typically cast at 0.75” to 1“ thick. Mixes can be modified for sprayed applications or plasticized with water reducer to create self-consolidating concrete.

Materials, Simplified

Buddy Rhodes Concrete Products

Buddy Rhodes Concrete Products

- A GFRC blended mix of cement, sand, dry curing polymer and admixtures. For example, the Buddy Rhodes GFRC Blended Mix already contains the proper ingredients and high-performance admixtures for making thin, lightweight concrete or any GFRC project.

- 3/4” long, chopped Alkali Resistant (AR) Glass fibers are added separately to impart critical flexural and tensile strength.

- AR Glass Fiber Scrim is a woven fabric that can also be added for additional, targeted reinforcement.

- Super Plasticizer/Water Reducer can be added as a wetting agent to reduce water content, improving ultimate strength.

First, Formwork

Buddy Rhodes Concrete Products

Buddy Rhodes Concrete Products

Casting: The Spray Technique with Hand Laid Backer Mix

The GFRC Spray Technique is accomplished in two stages: a surface layer (face/mist coat) without fiber, followed by a structural layer (backer mix) containing AR Glass Fibers. There are no fibers used in the face coat mix as you don’t want the finished surface to show fibers. Begin by adding 1 gallon of water and 2 oz of water reducer to a 17.5-gal bucket. Slowly add one 50-lb. bag of GFRC Blended Mix and blend thoroughly with a hand-held mortar mixer with a high-viscosity paddle. Allow the mix to sit for 10 minutes to “false set,” then remix, adding water reducer as necessary to make the right consistency.

Buddy Rhodes Concrete Products

Buddy Rhodes Concrete Products

Pour the mixture into a drywall hopper gun for spraying. Your spray should come out of the gun like a wet splatter. This first crucial layer creates the surface detail of the casting and should be around 1/8” thick. With a bristle brush, brush the face coat in the mold to push out any air pockets, particularly in the corners and edges of the form to consolidate the mix.

Once the face coat is sprayed, begin mixing the backer coat. Timing is important — you do not want the face coat completely dry or the backer coat will not bond properly. Ideally you want the face coat mix to begin to stiffen so the backer coat does not push through while still getting a good bond between the face and backer coats. For the backer mix, blend more material exactly as was done for the face mix. Toward the end of the mixing process, add 1.5 lbs. of AR Glass fiber for every 50 lbs. of blended concrete. Slowly mix in the AR fibers while reducing the mixer rpm — mixing the fibers too vigorously will break down their structural integrity. Layer this behind your face coat. Total thickness depends on the size of the project, but 1” thick is typical. You can make a fluid mix that pours over the face coat, or you can make a thicker mix that is applied by hand. A thicker mix is especially useful for vertical walls.

Buddy Rhodes Concrete Products

Buddy Rhodes Concrete Products

It is recommended to trowel the back of the piece, particularly if it needs to rest on or butt up against a flat surface. There is no need for perfection on the back side of the piece since the back will not be seen, but it is important to have a flat, smooth surface for installation. After all concrete is placed, cover with plastic sheeting and allow to cure for a minimum of 16 hours at room temperature (73 degrees F / 23 degrees C).

Once the piece is demolded, fill any bug holes with a matching color paste, lightly polish with 200-grit diamond pads, and seal prior to installation. The same GFRC Blended Mix can be used when doing more traditional finishes like polished and hard troweled cast in place concrete. It’s also a great starter mix design for wet-cast mixes. Add up to 25 lbs. of 3/8” aggregate or similar to extend the yield and reduce shrinkage.

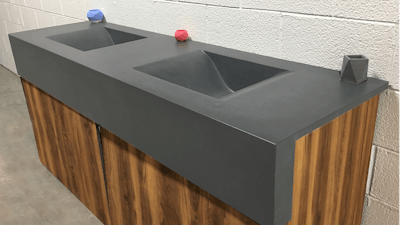

A vanity made with GFRC.Buddy Rhodes Concrete Products

A vanity made with GFRC.Buddy Rhodes Concrete Products

Buddy Rhodes Concrete Products offers a diverse line of materials beyond the GFRC Blended Mix. Create ultra-thin, high-performance concrete with our ECC Blended Mix. Try out the classic Buddy Rhodes Signature Pressed finish by using Craftsman Mix. Or make lightweight boulders, sculpture, and themed environments with Buddy Rhodes Vertical Mix. They also offer over 400 concrete pigments, topical glazes, sealers, and other accessory products for any artisan concrete project. Find how-to videos, technical support and more on their website: www.buddyrhodes.com.