At World of Asphalt 2018 Mar. 6-8 in Houston, Hamm will introduce to North America its unique PH hybrid power train system for tandem asphalt compactors. This innovative concept has been developed to save fuel, costs and maintenance work, benefiting all road construction and maintenance operations.

The totally new system combines the traditional internal combustion engine with a hydraulic accumulator. The internal combustion engine covers the base load while a hydraulic accumulator meets peak loads. At World of Asphalt Hamm is introducing the hybrid power train system in the HD+ 90i PH tandem roller.

Hybrid solutions combine two power technologies. In the automotive sector, combinations of internal combustion engine and electric drive in particular are common. Hybrid power attempts with electric motors in rollers proved unconvincing, so Hamm tackled this problem with a novel approach, combining an internal combustion engine with a hydraulic system, and became the first roller manufacturer to develop a technical solution suitable for series production.

HD+ 90i roller with hybrid power train

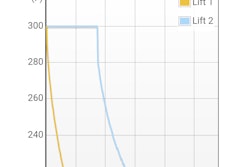

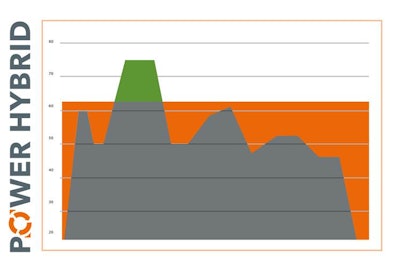

For the first hybrid power models, Hamm chose the HD+ 90i, a popular tandem roller in the medium weight class. Up to now, this roller has operated with a 114 hp (85 kW) diesel engine complying with EPA Tier 4f exhaust emission standards. A detailed examination of the actual engine load during compaction showed the Hamm developers that the peak loads were only needed occasionally and even then for just a few seconds. This is the case when the roller starts up for example or the vibration / oscillation is activated. In the new hybrid power roller, these brief peak loads are handled by a hydraulic system, enabling the roller to be equipped with a smaller diesel engine for the same performance. The load on the diesel engine is also reduced in that the radiator fans are electrically operated for optimum efficiency.

Hydraulic power storage on board

The hydraulic system works rather like a pumped storage power station: as soon as the power demand falls below the maximum load of the internal combustion engine, a pump fills the hydraulic accumulator. If a great deal of power is called for, such as when starting the vibration drive, the hydraulic system functions as an auxiliary drive, able to supply a maximum short-term load of up to 27 hp (20 kW). Following this the cycle begins afresh with the refilling of the accumulator. The principle functions splendidly because for normal applications, the maximum load is always only called up for a matter of seconds. Afterwards there is sufficient time to replenish the accumulator.

Quieter, lower fuel consumption and less maintenance effort

This results in numerous benefits: for example, the 9 mt HD+ 90i PH roller can be powered by 74 hp (55.4 kW) engine in place of a 114 hp (85 kW) unit – and with the same compaction power. The smaller engine does not require an SCR catalytic converter or DEF fluid. This results in advantages in terms of handling and maintenance. What’s more, the power train is markedly quieter. Last but not least, the hybrid power train in combination with the electric fan drives and a start-stop system enables significant savings of up to 15 percent in fuel consumption. This also substantially cuts CO2 emissions.

Available in North America from 2018

The hybrid system underwent field trials in selected markets during 2016 and 2017 and is expected to be available in North America with double vibration (VV) and vibration-oscillation (VO), as well as the smooth drum-pneumatic "combi" rollers (VT) as options in 2018.