Roller manufacturer Hamm revealed the upgraded Smart Compact Pro. This technology makes a decisive contribution to extending the service life of road surfaces and reduces construction and renovation costs as well as potential additional expenditures at the contractor's expense. The innovation is initially available in North America for tandem rollers from the HD+ series.

Hamm is now expanding Smart Compact by adding a central measured value – the real-time asphalt density. It is the decisive parameter for qualitative assessment during the compaction process and is becoming the key parameter for precisely meeting regulatory requirements and minimizing financial deductions.

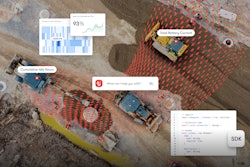

Smart Compact Pro closes this gap by integrating the new “Realtime Density Scan” sensor into the automated compaction process. This determines the asphalt density in real-time by measuring the dielectric conductivity of the asphalt mix to be compacted, forming the basis for the correlation with the asphalt density or the void content. Both parameters are decisive for self-monitoring or control testing. With the help of real-time density, Smart Compact Pro can provide construction companies with a decisive advantage by accurately implementing regulatory requirements.