By Tyler Mackay, Grant Mackay Company

Surreal. How else can you put it? Like taking down your childhood home, a place tied together with so many past experiences and memories, demolishing the Salt Lake City International Airport was an unreal opportunity for our team at Grant Mackay Company Inc. The project was was originally planned to take four years, but due to COVID-19 and the lack of traveling passengers, we completed it in eight months. The quick-pace schedule, combined with the inherent nostalgia and overall scope of work, proved to be a unique challenge that our crew was ready and eager to accept.

The post-tensioned, four-story parking garage, built in 1990, with concrete reaching 20,000 psi was an impressive demolition challenge.National Demolition Assoc.

The post-tensioned, four-story parking garage, built in 1990, with concrete reaching 20,000 psi was an impressive demolition challenge.National Demolition Assoc.

As the parking garage demolition was nearing its end, demolition on two terminals and four concourses ramped up. All had aggressive deadlines with unique challenges, including having limited access for truck routes due to other trades capitalizing on removing pavement and utilities next to the buildings.

Toughest steel ever

Another challenge of this project was that traditional ways of demolishing structures would not work. “It was as if they had found the best welders to fit the strongest steel made at the time of construction,” says Jason Cobb, the lead operator who oversaw the demolition of Terminal 1. “I said it multiple times that this has to be the strongest steel I have ever seen. The difficulty of the demo became easier as I hit the areas that were added on throughout the years.”

Both terminals were finished weeks ahead of an accelarated schedule, clearing the way for the new airport building footprint to also begin ahead of schedule.

Removing the four concourses also proved to be challenging, especially in controlling debris. “One challenge that could seem minimal on other demolition jobs was controlling the foreign object debris,” says Jeff Richards, a lead operator on the concourses demolition. “Any little gust of wind would bring us the stress of controlling Styrofoam, insulation and loose papers.”

National Demolition Assoc.

National Demolition Assoc.

Wind would, on a few occasions, shut down operations for the day, but that didn’t stop the crew from finishing all four concourses three to four weeks ahead of schedule.

One remaining difficult task that separated itself from the rest of the airport was the removal of two air traffic control towers that were iconic landmarks for those who worked and flew out of the airport for many years. Built of steel, both eight-story-tall towers were taken down using the Tripp methodology.

Hefty recycling totals

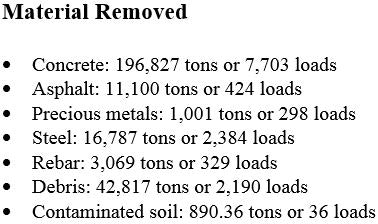

Totals from the job were nearly as impressive as the job itself. We had lofty goals of recycling materials from the buildings, and with just a month left to finish the job, we are pacing for over 84% of materials recycled. What took years to build was taken down in a matter of eight months, and 4.5 million square feet of material was taken out in trucks one scoop and one load at a time.

The Salt Lake City International Airport was a great job. We took great pride in it and are looking forward to the next challenge.

Tyler Mackay is a lead operator at Grant Mackay Company, where he has worked for six years. He is a fourth generation Mackay in the demolition business.