Losing small change on your construction projects can add up to thousands of dollars at the end of the year. So maximizing profit must be a top priority, right along with getting your projects completed on time.

You need to set aside time to focus on increasing each job's net profit. When you’re too busy working on the jobs, scheduling crews or doing work tasks, you don’t take or have enough time to focus on finances, financial tools and strategies that can help you hit your goals.

Consider implementing these two proven, project-level strategies that will maximize your bottom line and grow your bank balance.

Accurate general conditions

General conditions in construction include the onsite administration, supervision, temporary facilities, temporary protection and soft costs required to get your projects built. Estimating accurate general conditions for projects can be a simple task when the estimator is accountable to get it right. Most estimators use unit prices which are rarely checked against the actual final job costs. For example, creating a budget for temporary toilets seems easy. An eight month job should cost eight times $100 per month = $800. But when the field superintendent sees there are 40 men on the job, more than one toilet and more than one servicing a week is required. This might increase the actual job cost by as much as $200 per month. These extra costs will add up to lots of lost cash.

The estimator’s number one job and accountability is to calculate an accurate estimate of what it will cost to build each project. After every job he or she must look at the actual job costs to see if he miscalculated or under estimated any of the project line items. Before you price every job, the estimator should get with the project manager, field superintendent or foreman to determine what will be required to run the project he is currently bidding. Take a hard look to determine if you are charging the right price for:

- Project manager, superintendent and their vehicles

- Project photos, sign, as-built drawings, etc.

- Temporary facilities, trailers, toilets, sanitation, etc.

- Temporary utilities, electricity, power poles, water, phones, etc.

- Temporary fencing, gates, barricades, site lighting, heating, etc.

- Safety, first aid, shoring, access roads, security guards, etc.

- Water quality control, dust control, etc.

- Trash, cleanup, window washing, final punch-list, etc.

Charge for all the changes on change orders

Change orders are written documents amending the original contract agreement between parties memorializing an additional or changed scope, price, time, schedule, terms, or work item on a construction project. Most often they require additional money for the additional work required by the change.

As contractors, if you had $10 for every extra work item your company, project manager, field superintendent, or foreman did without a signed change order before the work was performed, could you have retired several years ago? When your customer asks for extra work, why is it so hard to get it in writing? Everyone knows the contract requires signatures on change orders prior to starting extra work. But when you postpone getting a formal approval for extra work until days, weeks or months after the event occurred, you have no leverage with your customer. And when you have no leverage, your customer is in a great position to settle or offer a reduced discounted price with you, change their mind or decide the additional work wasn’t really extra and should have been included in the original contract.

To avoid this problem, present a complete cost breakdown for every proposed change order your customer requests in advance of starting the work. Use a standardized format, cost template and rate sheet to make sure you include everything the additional work actually costs. Every time extra work is performed, the followings costs occur:

- Project management to process the paperwork

- Supervision to supervise the work

- Accounting to process the payment

- General condition costs as the job will take longer: trailer, toilets, water and utilities; power and power poles; trucks and equipment; small tools, ladders, bins, etc.; small items, nuts, bolts, hardware, etc.; temporary facilities, fencing, protection, barricades, etc.

- Liability insurance

- Overhead and profit

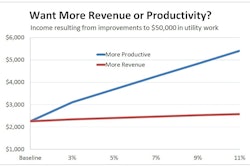

Don’t short change your company by not asking for everything you deserve. I see most change order requests presented as labor, materials and hard costs plus a markup without extra required soft costs for the many items listed above. If your company does $5,000,000 in annual sales of which $250,000 is performed as change orders or on a cost plus basis, not charging for everything you spend can cost you as much as $25,000 or more per year in lost revenue or net profit for things that you actually had to pay for.

Making money is not easy in construction. Look for every advantage you have to boost your net profit margin. Take the time to implement these tools and send me an email of the other tools you use to increase your net numbers.

George Hedley works with contractors to build profitable growing companies. He is a professional construction business coach, popular speaker and best-selling author of “Get Your Construction Business To Grow & Profit!” available at his online bookstore at www.HardhatPresentations.com. To sign-up for his free e-newsletter, be part of a BIZCOACH program, or get a discount coupon for online classes at www.HardhatBizSchool.com, e-mail [email protected].