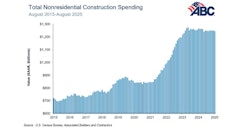

2026 is shaping up to be an important year for the infrastructure world as governments, cities and private developers deal with growing pressure on aging systems. Instead of focusing only on building quickly or staying under budget, more attention is shifting toward durability, long-term performance and overall resilience. The goal is no longer just to put a project in the ground, but to build something safer and better prepared for the next several decades.

Two big trends are driving this change. The first is the push for sustainability that can be proven with real data, and the second is the growing use of predictive, technology-enabled risk management. Together, these trends point toward a future where infrastructure is monitored continuously, proactively maintained to deliver measurable results over its full lifecycle.

Data Verified Sustainability

Sustainability used to be defined mostly by intentions, by using greener materials or trying to reduce emissions where possible. That simply isn’t enough as we move into 2026. Stakeholders want numbers tracking and transparency. They expect material choices and emissions claims to be backed by data. This has changed how projects are evaluated. Instead of focusing on speed or initial costs, discussions now revolve around how long an asset will last, how often it will need repairs and how it performs from an energy and carbon standpoint year after year. Benchmarks like digital traceability and long-term performance testing are becoming standard requirements.

This approach is also changing how infrastructure is designed. More projects now incorporate sensors, digital twins and automated reporting tools right from the start. These systems create ongoing feedback loops so owners and engineers can verify that sustainability goals are being met in the real world. Whether it is buildings, bridges, or energy systems, data is becoming the main way to prove that infrastructure is delivering on its environmental promise.

From Reactive to Predictive

Aging assets and more extreme weather are making traditional maintenance schedules less effective. Inspections that occur every few years can miss early warning signs, especially as structures age. In 2026, more organizations are turning to predictive risk management, which uses sensors, analytics and better materials to spot problems earlier. Engineers now have access to continuous monitoring tools that can track structural behavior in real time. Issues like corrosion, vibrations causing shifting and emerging cracks can now be identified earlier than before.

Bridges are a good example. Many bridges are at or past their intended lifespans, and traditional inspections can miss subtle changes that could grow into serious problems. With real-time monitoring and predictive analytics, engineers can catch early signs of stress, extend the useful life of structures and reduce the need for major repairs. Recent innovations allow the monitoring of critical structural parameters such as local defects or stress peaks from the point of installation of the structure. This can locate failures remotely as well as measure parameters such as localization of local defects, longitudinal variation of friction losses and local stress peaks due to cracking of the concrete, which previously could not be quantified.

Risk scoring systems are also gaining traction. These models combine historical information, environmental data, structural behavior insights, and real-time monitoring to predict where problems are most likely to happen. Organizations can then prioritize repairs, improve safety planning and avoid unexpected shutdowns.

A better understanding of materials is another part of this shift. Knowing how different construction materials behave over time helps engineers build more accurate models and plan for repairs or upgrades well before issues become urgent. Many organizations are working to build a more risk-aware culture where data, alerts, and transparent reporting are a normal part of operations.

Sustainability and Risk Management

Sustainability and resilience are no longer two separate goals. They influence each other directly. Infrastructure that lasts longer and requires fewer repairs is automatically more sustainable. And systems that are monitored continuously and maintained proactively are safer and more reliable.

More projects are pairing durable, environmentally responsible materials with sensor networks and monitoring tools. This creates infrastructure that can adapt as conditions change while still meeting safety and sustainability expectations. New reporting platforms can help owners track both environmental impact and asset health in one place, making it easier to manage long-term performance and make informed funding decisions. Investors and public agencies are also paying attention.

Preparing for What’s Ahead

Infrastructure decisions in 2026 and beyond will be defined by long-term thinking, smarter investments and better use of data. Speed will still matter, but sustainability and safe performance will matter more.

Engineers and public agencies will work together to put durability and lifecycle planning at the center of project design, use digital monitoring and predictive tools to stay ahead of risk, report on both environmental and operational outcomes in clear, measurable ways, and build on a culture that values long-term reliability over short-term wins. The infrastructure we build today must serve communities well into the future.