In today's construction landscape, staying ahead of risks and ensuring the safety of teams is paramount. To remain vigilant, businesses should redefine their approach to this critical aspect of work by embracing emerging technologies, such as artificial intelligence (AI), robotics, and advanced job-site cameras to support their commitment to safer jobsites and achieve better project outcomes.

There are five areas construction companies should assess for safety – human-machine interface, falls, energized systems, line of fire, and lifting operations – in which a staggering 93% of all serious incidents on construction jobsites occur. Focusing safety efforts on these key areas reinforces safety standards, promotes consistent planning, and cultivates responsibility. In addition to assessing safety efforts, businesses can rely on advanced technology to monitor safety conditions, alert potential hazards, and enable quick responses, ensuring the well-being of all team members.

Through consistent safety evaluations and innovative use of technology, the construction industry can commit toward creating a safer working environment for everyone.

AI's predictive power allows companies and their workers to proactively identify potential hazards, enabling timely interventions that can prevent accidents before they occur. Site safety cameras act as ever-watchful eyes on the ground, providing real-time data that helps monitor operations closely and allows for swift reactions should any signs of danger occur. The introduction of robotics is adding another layer to how the industry approaches safety. From automated equipment checks to performing tasks in hazardous conditions, robots are reducing risks associated with manual labor and improving overall site safety.

Together, these technologies are not only transforming how companies and workers maintain and enhance safety standards across all jobsites, but they are also redefining what it means to work safely in construction.

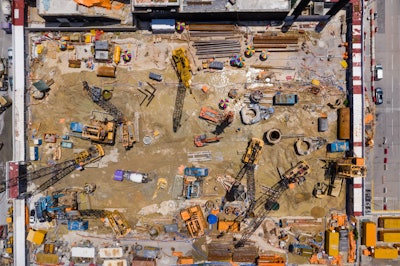

Enhancing Safety on Jobsites with Drones

Aerial drones have become everyday tools used by teams for real-time monitoring of construction progress. Drone-captured data offers valuable insights into project status and improves quality control measures. By leveraging drones for tasks like roof inspections, construction teams can remotely identify potential safety hazards. This lowers the possibility of fall accidents and reduces the need to work at dangerous heights.

The integration of new technologies is also not a one-time event but rather an ongoing process that demands continuous improvement.@trongnguyen - adobe.stock.com

The integration of new technologies is also not a one-time event but rather an ongoing process that demands continuous improvement.@trongnguyen - adobe.stock.com

Similarly, the adoption of underwater drones addresses the challenges inherent in waterfront construction projects. These projects often entail unpredictable conditions, necessitating labor-intensive and hazardous physical diver inspections. By deploying underwater drones, companies can enhance visibility into underwater construction conditions while eliminating the need for on-site divers. This both mitigates safety concerns for divers and preemptively addresses unforeseen issues during construction, aligning with the commitment to creating the safest possible jobsites.

Drones can also be equipped with sensors that can detect heat signatures. These advanced machines can identify early signs of fires or equipment overheating, revolutionizing the way we safeguard against potential hazards.

Advancing Safety with Terrestrial Robots

Companies should look for opportunities to pilot terrestrial robots tailored to specific construction tasks across jobsites. In limited testing, these tools, focused on automating layout and installation processes, have shown promising results, including increased safety standards, improved worker productivity, and accelerated project schedules.

Currently, there is technology available using BIM data to autonomously print trade-layout lines. Tasks once physically demanding and potentially hazardous can now be executed automatically with precision and efficiency, reducing the likelihood of worker injuries. Similarly, these innovations represent a leap forward in semi-automated drilling technology, enhancing productivity and safety on projects. Technology of this nature relieves construction workers of the physically taxing process of overhead drilling by precisely marking and drilling holes for mechanical, electrical, and plumbing installation while following digital drawings as the guide.

By automating dangerous and repetitive jobs, robots can enhance workers' safety by lowering the possibility of accidents and injury. Additionally, by leveraging robotic technology, it allows companies to navigate challenging or hazardous conditions with increased safety, guaranteeing that safety is always a top priority across all phases of the project lifecycle.

Rather than replacing workers, robots often serve as a complement to them - taking over mundane or dangerous tasks and allowing teams to focus on more strategic or complex problem-solving activities.

Empowering Safety Through Advanced Site Cameras

Advanced site cameras are essential for improving operational effectiveness and safety on the jobsite. Equipped with features such as remote monitoring and high-resolution imaging, these cameras provide real-time visibility into project progress, enabling proactive risk management. By integrating AI and computer vision, site cameras can automatically identify safety hazards and enhance site security, which helps promote a culture of safety excellence.

Moreover, site cameras serve as valuable tools for documenting safety procedures and conducting incident investigations. Construction teams can conduct in-depth analyses of safety accidents, pinpoint the underlying reasons, and put corrective measures in place to stop them from happening again thanks to high-definition video footage. Also, remote access to site camera feeds allows project stakeholders to monitor safety protocols in real-time, facilitating immediate intervention in case of safety violations or emergencies.

The application of AI and robotics in construction paves the way for enhancements that last well beyond the project-completion phase.@kosssmosss - adobe.stock.com

The application of AI and robotics in construction paves the way for enhancements that last well beyond the project-completion phase.@kosssmosss - adobe.stock.com

Transforming Safety Behaviors with Video Intelligence

Site safety cameras equip experts with the ability to review and optimize performance based on captured video footage, similar to the post-game analysis in sports. Strategically positioned cameras in areas of high work activity enable workers to identify risk profiles.

Leveraging machine learning can enhance analytics capability, aiding in identifying these conditions and capturing essential data for thorough quality assessment. Portable cameras on jobsites diligently record video throughout the day. This footage can be subsequently audited overnight using AI technology and time-lapse searches, enabling workers to monitor energized equipment, live loads, workers on ladders or lifts, and more.

These cameras can then compile data into comprehensive daily and weekly reports - complete with flagged videos - which are sent directly to frontline supervisors via tablet-based Power BI applications.

When reviewing these video clips, site managers can see that many of the captured incidents may have otherwise gone unreported. Because of this technology, it provides a valuable opportunity to learn, communicate, mentor, coach, and ultimately change behaviors. Sharing these videos with people on the jobsite can help workers understand unsafe behaviors. These videos act as powerful tools that allow supervisors to show workers how certain actions put themselves and others at risk; they effectively shift the conversation and help influence safer behavior.

Video intelligence provides an avenue for identifying behaviors that need improvement while also facilitating positive reinforcement. Moreover, it allows companies to spot unforeseen risk conditions such as improper ergonomics or inadequate ladder usage (such as maintaining three points of contact), offering further opportunities for mentoring.

This iterative process of data analysis sets the stage for predictive analytics, which means companies are better equipped than ever before to enhance safety measures continually.

Safety Post-Construction

The application of AI and robotics in construction paves the way for enhancements that last well beyond the project-completion phase. Their utility is not confined to just the building process; they also guarantee long-term benefits that contribute significantly to safety and operational efficiency.

By capitalizing on AI, robotics, and automation, construction companies are able to construct 'digital twins' of buildings - virtual models that mirror their physical counterparts. This digital replication allows workers to plan maintenance proactively and monitor a building's performance in real-time. For instance, AI algorithms can be employed to analyze data from various sensors integrated into a building's systems. These algorithms are adept at identifying anomalies or deviations from established safety benchmarks in this data.

These advanced technologies not only enhance safety standards during construction but also establish a foundation for safer, more efficient operations throughout the lifespan of our buildings. By emphasizing health and safety from the construction phase and extending it well into the future, workers can ensure each project’s long-term wellbeing.

Empowering Safety Through Innovation

The integration of AI, robotics, and advanced site camera systems presents enormous potential to improve safety outcomes for project teams. Leveraging AI allows for better data analysis which can inform safer work practices on jobsites. In turn, decisions based on accurate data lead to more effective risk-management strategies.

The implementation of these technologies requires workers to acquire new skills and knowledge. It’s important to invest in training programs that keep teams up to date and ensure workers and teams feel empowered to accurately and regularly use these technologies once introduced.

The integration of new technologies is also not a one-time event but rather an ongoing process that demands continuous improvement. Regular evaluations should be conducted to assess the effectiveness of these technologies and make necessary adjustments or improvements.

By aligning emerging technologies with safety initiatives, the industry can reinforce its dedication to creating safer jobsites, fostering a culture of responsibility, and delivering projects that uphold the highest standards of safety and quality.