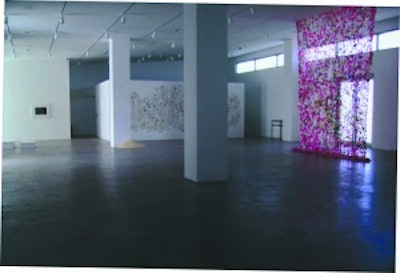

Often, concrete floors are pieces of art. But what happens when the floor is for an art gallery and should not be the focus of attention? CRS of Ft. Lauderdale Inc., Fort Lauderdale, Fla., completed a 28,000-square-foot job in November 2009 where this was the case.

CRS was asked to complete three concrete floors as well as the stairways for the de La Cruz Collection in the Miami Design District, says Glen Barrett of CRS. The owner wanted concrete floors with even coloring and no exposed aggregate so guests in the art gallery were looking at the art and not distracted by the floor. Barrett, who says CRS focuses on making concrete not "look" like concrete, had just the idea to create the floor the customer wanted.

Barrett suggested a faux finish on the floor which would result in even concrete with a slight mix of light and dark color. CRS used Rapid Set Cement from CTS Cement Manufacturing and was able to complete the job in seven weeks. "The Rapid Set gives the floor a mottled look with a uniform color," Barrett says.

Before applying the Rapid Set, a cleaning crew came in to sweep, sand and vacuum the existing concrete floor. To get the desired look, Barrett followed a three-step process with the Rapid Set Cement. He applied the first coat of Rapid Set Cement - the skim coat - using a hand trowel and circular motions. "You apply it with a circular application so you have no linear lines on the concrete," Barrett says. He then troweled water over the first coat to help harden the skim coat. Barrett followed with a second coat of the Rapid Set, which when dry hardens to 3,000 psi, he adds.

To seal the floor, Barrett applied a Zep water-based sealer. He chose water-based because, unlike a solvent-based sealer, it does not darken the color of the concrete. "We applied three coats of sealer to get a more uniform look," Barrett says. "Some areas of the floor were more porous than others so we needed three coats to even out the sealer and get a low sheen."

The application process had to be modified for the stairs because there was less room to work in. After applying the second coat of Rapid Set, Barrett sanded the stairs with 120 grit sandpaper to get the smooth surface.

For a job like this, troweling is key, Barrett says. It was important for the CRS crew to take its time and get the job done right the first time. The crew worked slowly to ensure no trowel lines were left behind. To eliminate any excess material on the floor CRS confronted the problem before even starting. Barrett and his crew used the "less is best" process for this job. Applying less material allowed him to create a smoother floor that was a work of art but not the focus of the gallery. And owner Rosa de La Cruz said, "The look was exactly what I wanted."