So much depends upon a structure’s foundation. This mostly unseen element can mean the difference between a long-lasting building and one that will need substantial repairs over its lifetime. As such, it’s important that concrete professionals take every step possible to ensure a foundation that can withstand all the forces of nature that act on a building. Doing so will increase their customer’s long-term satisfaction with their work and improve their reputation within the industry—both of which can unlock more business overall.

But other than following best practices for foundations, what can contractors do to improve the quality of foundations they pour? Choosing concrete that maximizes its potential is one step toward more resilient foundations. Structural lightweight concrete (SLC) made from expanded shale, clay or slate (ESCS) aggregate not only provides several benefits to make foundations more durable, but it also alleviates concerns about tensile strength associated with other lightweight concretes. The following will explore these qualities and how they can improve the quality of all concrete elements, including foundations.  The dead load was reduced by 25-30% using lightweight concrete in the floors of the Comcast Center.Courtesy of the Expanded, Shale, Clay and Slate Institute

The dead load was reduced by 25-30% using lightweight concrete in the floors of the Comcast Center.Courtesy of the Expanded, Shale, Clay and Slate Institute

Reduced Deadloads & Improved Thermal Resistance

SLC has a lower density than standard concrete, which can reduce the deadload of an entire structure. A lighter building will reduce pressures exerted on the soils beneath the foundation, thereby reducing the degree to which the ground below the structure will compress. This mitigates the tendency of foundation failure due to settling, since the soil will endure less pressure. Of course, the amount of deadload reduction depends on how much concrete is used throughout a building. However, given that SLC is typically 25-35% lighter than normal-weight concrete, it can contribute to a lighter structure even when used only in the floors and foundation.

Additionally, the coefficient of thermal expansion is lower and the thermal conductivity of SLC can be half that of normal-weight concrete. As a result, it reacts to temperature change more slowly, thereby lowering the risk of cracking caused by extreme differences in temperature. While these characteristics are often touted as contributing to more energy-efficient and fire-resistant structures, they also contribute to foundations that resist cracking due to temperature differences between internal and external temperatures because SLC more uniformly distributes the temperature-related stresses.

Both qualities improve the long-term resiliency of a foundation for longer-lasting structures. This can lead both to more satisfied building owners and potentially more business from word-of-mouth recommendations.

Reduced Potential For Early Age Shrinking & Minimized Permeability

In addition to SLC’s physical characteristics, the material also benefits foundation construction due to its compositional properties. Early age shrinkage and cracking can be the first steps toward a crumbling foundation. However, because SLC cures internally, it reduces the tendency of concrete to shrink and crack during curing. Essentially, the absorbed moisture within the ESCS aggregate is released as the cement hydrates, contributing to a more uniform curing process. It also strengthens the bond at the interface between two materials (aggregate particles and cementitious paste), furthering mitigating concrete’s tendency to crack.

The increased bond strength between lightweight aggregates and cementitious paste also reduces SLC’s permeability. As reported in a 2008 paper presented at the Concrete Bridge Conference, SLC can have an average chloride permeability rating of 989 coulombs, less than half of the code-driven limits for commercial and infrastructure projects. Generally, highly permeable concrete allows ingress of harmful chemicals, which can lead to the corrosion of steel rebar via chloride attack. This weakens the structural integrity of the concrete. For foundations, a less permeable concrete is more able to evade chloride and sulfate attack from the soil. It also contributes to foundations that more readily resist damage from freeze-thaw cycles, since there would be fewer chances for water to find its way into and widen micro-cracks.

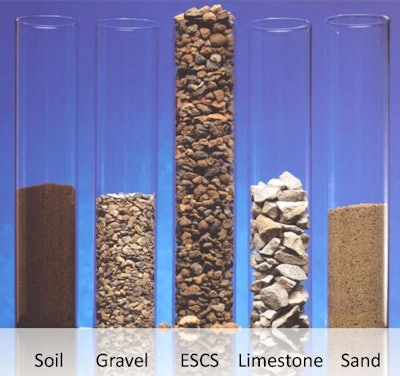

These benefits are both immediately noticeable and detectable over the course of a foundation’s service life—offering crucial proof points to the improved quality of concrete used.  A comparison of 1 lb. of lightweight concrete aggregate to other conventional options.Courtesy of the Expanded, Shale, Clay and Slate Institute

A comparison of 1 lb. of lightweight concrete aggregate to other conventional options.Courtesy of the Expanded, Shale, Clay and Slate Institute

Addressing Ductility Concerns With Improved Fracture Behavior

While the above qualities can help maximize the immediate and long-term potential of concrete foundations, it is important to note that SLC has a lower tensile strength than standard concretes. This can increase the likelihood of cracking when soils shift from settling, frost heave or other forms of movement. However, the similarity of the stiffness of the cementitious paste and the lightweight aggregate particle reduces stress concentrations within the concrete. This can be readily seen, as cracks in normal-weight concrete tend to go around the aggregate, while cracks in SLC often propagate through the lightweight aggregate. This “strain compatibility” reduces the tendency for SLC to crack under normal loading.

According to a 2003 paper by Frank Dehn, building materials and concrete construction professor and director of the Material Testing and Research Laboratory, SLC made with ESCS lightweight aggregate displays fracture behaviors somewhere between other SLCs and standard concretes. This translates to a ductility that is closer to that of normal-weight concrete, which can be improved further through the incorporation of fibers or steel reinforcements. Though these methods for improving the ductility can be used on all types of SLC, the SLC made with ESCS requires minimal adjustments, reducing any significant changes to the material’s performance capabilities.

By reducing the ductility differences between SLC and normal-weight concrete, ESCS lightweight aggregates help contractors pour more resilient foundations while offsetting a major concern some professionals have when considering types of concrete. As such, SLC made with ESCS can drastically improve the quality of concrete foundations, and high-quality foundations often require fewer repairs and maintenance through the years, potentially saving building owners money on the long-term cost of a project. Communicating these benefits during negotiations can improve the efficacy of a contractor’s bid (even when that bid includes higher material costs).

Lightweight concrete can reduce permeability for strong foundations. The foundation of a water tank in Denver.Courtesy of the Expanded, Shale, Clay and Slate Institute

Lightweight concrete can reduce permeability for strong foundations. The foundation of a water tank in Denver.Courtesy of the Expanded, Shale, Clay and Slate Institute

The Right Aggregate For Long-lasting Foundations

Pouring the most structurally sound foundations largely depends on following best practices for a given site and environment. That said, contractors can improve the immediate and long-term performance of their foundations by looking at the type of concrete they use. SLC mitigates the tendency of concrete to crack during curing and the material’s overall permeability. Further, it improves concrete’s thermal resilience for reduced strain from differences between internal and external temperatures, all while lessening the deadload a structure places on the soil.

These qualities sideline many issues that crack concrete, which improves a foundation’s long-term structural viability. When SLC is made with ESCS, it also increases the material’s ability to mitigate the damage a crack can cause. Contractors can use this information both to improve the concrete they pour and to increase the satisfaction of their customers.

About the Author

Jeffrey Speck is the General Manager of Marketing and Technical Sales at Arcosa Lightweight. Jeff has more than 30 years’ experience in the lightweight aggregate industry. He serves on the Expanded Shale, Clay and Slate Institute (ESCSI) Board of Directors and actively participates in numerous committees.

Article provided by the Expanded Shale, Clay and Slate Institute.