Being involved in the decorative concrete business for over 25 years, I've learned some very important lessons - as well as some costly ones - that have resulted in many sleepless nights. Early on, a good percentage of these miscellaneous mishaps and blood-shot-eyed nights could have been avoided had we implemented a good sample program from project to project. Samples can be one of the most important considerations on your job for a variety of reasons, such as letting your client know what he or she can expect texturally, how the color looks, and whether the sealer is too glossy or not shiny enough, just to name a few.

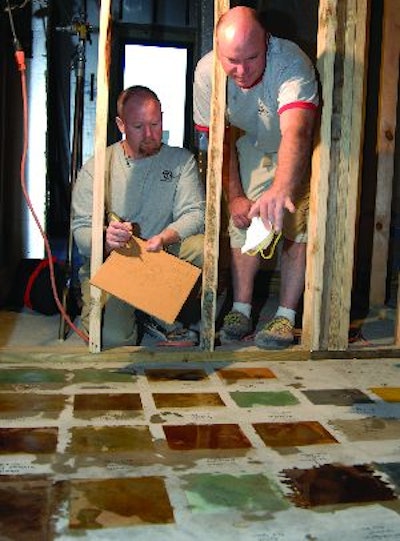

While working in the theme parks in Orlando back in the early 1990s, it was not uncommon for us to pour 10 to 20 cu. yds. of concrete samples a week so the Disney architects could hone in on the desired color and texture. In addition, the samples demonstrated the skill of the workers almost as if the pre-performance was being judged. It also established a standard to refer back to throughout the duration of the project, which leads me to a very important point - when producing your jobsite samples, it is imperative to fabricate a sample that will best represent jobsite conditions, especially in a commercial setting.

If you make your sample pristine and fit for an art gallery, this will be expected throughout the entire project, which is next to impossible to achieve. Remember, you are working with concrete, an imperfect product, which has many different performance unknowns that are never the same from load to load. You're also working in an imperfect environment with wind, rain, sun and hopefully not snow! To prove the importance of sampling, on a past high-end, 5,000-sq.-ft. project we really wanted due to the historical significance, not to mention it was in our hometown, the competition had submitted a 2-ft. by 2-ft. homely little sample. We poured a 10-ft. by 10-ft. sample at the owner's expense with the agreement that if we were awarded the contract, we would deduct the cost of producing the sample off of the overall contract. The end result of the sample was we were awarded the contract at $10 per sq. ft.

Although there are manufacturers that provide their customers with color charts depicting stain colors, color hardener or release colors, remember these are laminated pieces of paper. They should only be used as a starting reference for the clients to narrow down their color selection. Also, be careful when submitting small concrete samples produced by the manufacturer since they are cast in laboratory conditions and can sometimes give a false representation of what the actual color or texture would look like over a large area. These types of samples, however, are great for architects to keep in their libraries as a reference.

Residential sampling

So you're not stamping or staining huge commercial projects but rather small residential jobs. Do yourself a favor and do not skip this important aspect of your project. When staining, if possible, always sample the actual concrete you are proposing to stain. This may take place underneath a stairway, a hallway closet, or a room that you know will be carpeted or tiled. Sampling in this fashion allows your client to view the actual concrete and of equal importance, it demonstrates to you how the substrate is reacting. If sampling on the concrete is not an option, here are a couple valuable tips you can use to create your own samples for submittal reasons or for simply practicing your techniques on:

- Purchase bagged concrete mix (Sakrete 5000) and add an additional 30 to 40 lbs. sand and 30 to 40 lbs. cement. You now have a decent concrete mix that, depending on how you finish it, will provide a sample resembling ready-mixed concrete.

- Molds can be as simple as taking a $3 Teflon pan and coating it with some liquid release as a bond breaker and then filling it flush with concrete, screeding level and finishing it to the desired smoothness. This is a great way to create samples since they are lightweight. You can also use melamine or laminate to cast on, framing up the sides roughly 1 to 11/2-in. thick. The nice thing about this method is both the cast side down and the top portion can be used.

- If the project requires a cement-based overlay, a very cost effective way of creating your sample is purchasing 3-in. by 5-in. tile backer board, which comes in different thicknesses typically ranging between ¼ in. and ½ in. Follow the overlay manufacturer's technical guidelines for priming (if required) and mixing and then skim the tile board. Once complete, you can cut the sample board into smaller pieces and use them as sales tools, distributing them to you prospective clients.

Charge for samples

A word of caution, sampling can become time consuming and costly. A recent high-end project proved this point when clients wanted us to recreate a simulated river through the middle of their home.

After many excursions to their property (fuel prices are sky high), taking pictures of the property's stream and coming up with just the right formula, we ended up not getting the project because the client had no clue as to what a project like this would cost despite pricing it what we thought was fair. Shame on us for letting our passionate side rule!

Don't be ashamed to charge for your samples. Possibly offer the first and second sample at no charge with each additional sample costing $500 (of course depending on the size). One of two things will happen - either the customer will stop nickel and diming you with sample after sample, or they will take their project seriously and gladly pay the additional charge realizing the importance of the final selection.

Good luck with all of your projects and do yourself a favor - if you're not currently sampling on your projects, you may want to consider starting for peace of mind and a good night's sleep!

Bob Harris is the founder and president of the Decorative Concrete Institute, Temple, Ga., which provides hands-on training in architectural concrete. He has personally placed or supervised the placement of more than 3 million sq. ft. of decorative concrete and is the author of a best-selling series of decorative concrete books and DVDs. For more information, call (877) DCI-8080 or visit www.decorativeconcreteinstitute.com.