Throughout the last five years the surface preparation industry has been steadily growing. More and more contractors and manufacturers are entering the field. This means a multitude of information about how to perform various applications is available. Conflicting information can make it difficult to identify the correct application method, and trial and error on a customer’s floor can be costly.

One of the main services a surface preparation contractor performs regularly is restoring an older concrete floor. Normally these floors have been covered with another surface such as tile, carpet, paint or epoxy. If the material and old adhesive are not removed properly, the final floor can be affected with less than ideal results. There are several steps that need to be taken to ensure the materials are removed properly to create the ideal base.

Step 1. Selecting The Right Grinder

If a machine is too large, too small, too powerful or under powered it can affect the operator and the floor. To select the right grinder, there are several considerations that need to be made.  Contractors can remove a thick residue from a concrete surface with the right grinder and diamond combination.

Contractors can remove a thick residue from a concrete surface with the right grinder and diamond combination.

Jobsite size. The size of the floor will help determine what size of grinder to use. If the floor is small, such as a garage or home basement, a small single disc grinder is sufficient. If the floor is a department store, warehouse or other large area, a large multiple-disc grinder is more efficient.

Power available. Knowing what type of power is available at the job site or whether a generator will be needed is another important factor. Grinding machines come in 115-volt single-phase, 220-volt single-phase, 240-volt three-phase and 480-volt three-phase power.

Most single-phase machines can be powered by a residential or industrial building’s outlet. This makes set up and tear down easy because an alternate source of power is not needed. A three-phase machine is generally more powerful and uses power more efficiently than a single-phase machine. However, three-phase machines might have to be powered by a generator if the project is not in a specialized facility that has 480-volt three-phase power in house.

Final floor. Taking into consideration the final surface is key to selecting the right grinder.

Single disc, or head, grinders are the perfect tool for removing an old surface covering in anticipation of a new covering or treatment. Their high RPMs remove tough coverings, such as glue, paint, older concrete, leveling compound and even epoxy easily. After grinding, the surface is level, free from debris and is just rough enough to bond with new floor coverings.

The single disc grinders might also be able to polish, but might not be the best choice for polishing. The single-speed and high RPMs can wear out the diamond tooling quickly and the single head might also leave heavy scratches.

Multiple disc, or planetary machines, with multiple heads and variable speed are much better for polishing. In a planetary machine, the satellite head spins and the planetary drum spins. These separate actions give the operator more control and ultimately help refine the scratch pattern from step to step. This ensures a smooth, consistent surface.

Grinder size. The weight of the machine also plays into how it grinds. The heavier the machine, the more it will grind. The weight enables the machine to keep the diamond tools in contact with the material to be removed or the concrete, enabling it to grind more efficiently.

Vacuum system. It is also important to select a vacuum system for the grinder. Containing dust and debris is critical to maintain a safe and environmentally friendly work site. The dust created by grinding can be potentially hazardous if inhaled for a long period of time. The use of a vacuum system that efficiently filters (99.9% @ 1 micron) fine particles protects operators and the surrounding environment. A wet/dry vacuum is ideal if a combination of wet and dry grinding methods will be used.

Step 2. Selecting The Right Diamond Tools

A rule of thumb to keep in mind is: Hard concrete floors and coverings (such as epoxy), need a softer bonded metal tool. A harder bonded metal tool is used on soft concrete floors and abrasive coverings.

Every diamond manufacturer has recommendation charts to help contractors determine which diamond tools to use to remove various floor coverings. Once the correct diamond tools have been determined, there is a proper way to set up the diamonds to ensure they work efficiently.  Grinding glue off a concrete floor.

Grinding glue off a concrete floor.

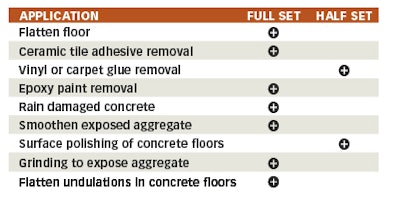

Grinding disc set-up. Since grinding discs can hold a number of diamonds, it is essential to know the differences between using a half set or a full set.

A half set of diamonds means diamond tools are placed at three alternating positions on the diamond holder disc. When the diamonds are set-up as a half set, they tend to follow the surface of the floor. It is similar to a tripod for a camera, which can be placed on an uneven surface and still find stable footing. A half set puts more weight per square inch on the diamond tooling, making it grind more aggressively on hard floors. It does not completely flatten the floor.

With a full set, diamond tools are placed at each of six positions on the diamond holder disc. The full set of diamonds is used when a flat floor is desired. It grinds the high areas and misses the low spots, resulting in a smooth surface with no undulations.

In addition to metal bonded diamonds, a PCD (polycrystalline diamond) scraping tool might be necessary to remove heavy coatings. It is not recommended to use a PCD scraping tool directly on a concrete surface. If a PCD is required, an operator should start with the PCD tool, remove around 75 percent of the material and then use diamond tools to remove the remaining material.  Table 1. Know when to use a half set or full set of grinding discs.

Table 1. Know when to use a half set or full set of grinding discs.

Step 3. Grinding Process

Now that a grinder and diamonds have been chosen, it is time to start grinding. Concrete grinding is the simplest and most efficient method for leveling and restoring a concrete floor. While the grinder removes coatings, it creates the perfect base for a new floor covering.

Material can be removed by either using a dry grinding or wet grinding method. While both methods have the same end result, there are a few differences in the process:

Dry

- Production rates will be slower on harder materials than wet grinding

- Softer bond segments are required in order to encourage even segment wear

- Scratches from diamond grit will not be as deep when compared to wet grinding

- More heat is generated by the diamond segment

- Cleaner work environment

Wet

- Production rates will be higher than when dry grinding

- Diamond segments will wear faster due to the presence of abrasive slurry

- Scratches from diamond grit will be deeper

- Longer clean up time

Which method to choose is a personal preference. When either dry or wet grinding, start with a coarse grit diamond tool and progressively work down to fine grit tools — depending on the desired specification. Changing the size of the diamond grit to a smaller particle/grit size gradually removes scratches in the concrete and creates a fine scratch pattern. This creates a good bonding surface for a new floor covering.

After the grinding process has been completed, the final result is a good base for either a polished floor or another surface. Ending with the perfect base floor means the next step(s) will be finished more efficiently. Taking the time to think through the process and plan accordingly will make the project more efficient, easier and the customer will be happier in the long run.