In 2012 Jim Cuviello, owner of Cuviello Concrete (Stevensville, Md.) was asked to do an AIA presentation for an architect designing an elementary school and an owner who wanted to use polished concrete. Several weeks following the presentation Cuviello was asked to review the proposed plan, cast-in-place and polishing specification.

Through the design process the architect looked at the finished polished concrete floor in its entirety including the production of the substrate to be polished (the finished slab), the polishing process, protection from construction through maintenance training.

The project went out to bid in 2013 and Cuviello Concrete was awarded the work.

Challenges

The construction manager put the polishing work into the division three package. This was done in an attempt to keep everyone from pointing fingers for failures, it holds one company responsible. In theory this should work. The reality is the division three contractor didn’t understand polishing and by the time the polishing work was performed they had completed their work and were focused on other jobs.

Respecting the chain of communication is preferred, but a concrete polisher then has to convey information to the cast-in-place contractor who doesn’t understand which in turn, has to now be explained to the construction manager.

The cast-in-place contractor is also focused on other work and the polishing portion does not get the proper attention it needs from the division three contractor.

Communication when doing polished concrete projects is critical and communicating through another sub-contractor causes communication break down and problems.

Shortly after receiving the job, the first of several meetings were held to get all parties involved in the project to understand what responsibilities they had to ensure its success. The construction manager had to better understand the process overall. The cast-in-place contractor had to understand the finishing requirements. The architect and owner had to understand the limitations and what to expect from the processes.

Although the specifications were well written in terms of the process, the construction manager did not understand the time requirements for the polishing process. The cast-in-place contractor did not fully understand the time it was going to take to achieve the level of detail required for polishing. And the owners expectations were based on pictures. (No one shows pictures of bad work.)

The design was a mix of one color of integrally colored concrete with sand aggregate cuts surrounded by a different integral color with course aggregate cut accents. This presented challenges for the division three and polishing contractor. The division three contractor had to place the course aggregate accents higher than the areas being cut to a sand aggregate. This meant the course cut accents and sand aggregate cuts had to be placed and finished independently.

The polishing contractor then had to cut the accents level with the sand aggregate cut area. Mating two different degrees of cuts next to one another requires a lot of hand work so the two cuts remain and look independent of one another.

The mock-up phase

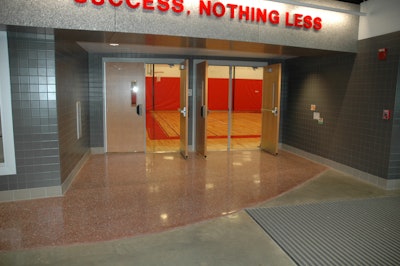

The time came to produce the mock-up which was to become part of the finished work. The mock-up was done in a back of the house corridor.

Although the architect knew polished concrete is not manufactured in a factory setting where everything is controlled, the construction manager did not. When the mock-up was done several meetings and phone calls were required to explain that perfection is not what polished concrete is, even though this was explained several times in previous meetings. The construction manager did not think the architect was going to accept the product. The construction manager was convinced to bring in the architect who looked at it and said “that’s great.”

A mock-up is one of the many steps in not only managing expectations of the owner/architect but also the general contractor or construction manager. As the sub-contractor, Cuviello will tell all the project participants what it is and the purpose it serves.

“The mock-up is used by the architect as a reference and general guide as to the appearance of the finished product,” Cuviello says. “It is also used to show the depth of cut, the aggregate exposure, clarity of the cut surface, color, natural variations and quality of workmanship.”

While valuable to the process, understanding the role a mock-up plays in a project is key to managing expectations.

“We say this because no two concrete pours are the same and will/may have differences,” he says. “Mock-ups can also be dangerous because it is easy to make small areas better than what an overall area may lend its self to because of the nature of finishing concrete.”

Pre-construction meeting

Cuviello says pre-construction meetings usually happen later than they should.

“The polished concrete portion of the project should be awarded to a contractor at the same time as the cast-in-place portion,” he explains. “A first meeting should happen early in construction and a second meeting before the pour.”

The first meeting is to allow the general contractor to understand how the polishing is coordinated in the schedule and time for the cast-in-place contractor to digest the information and make changes as needed.

The second meeting is a review and to tighten up information. Both meetings should be attended by the architect and owner so their expectations can start to be managed.

Managing expectations

Not managing the expectations of the owner/architect will ensure a contractor is set up for failure.

“If the owner/architect doesn’t understand what can and cannot be done within the time constraints and associated costs, the expectation is perfect,” he says. “But there’s more. Not just managing expectations once, but throughout the project and documenting how, when and what these expectations are is the difference between success and failure.”

Cuviello says if polished concrete contractors want to ensure success, site visits, photos of the ugly, site visits while the polishing process is taking place and making sure there is an understanding of the process will go a long way to success. Always remember to document the visits and remind the customer about what they are expecting to see.

Now bring in the principal. Throughout the project Cuviello managed every ones expectations including the “owner”. The owner in this case should have been considered the principal not the construction manager. The construction manager’s expectations were managed, he understood what polished concrete was and what to expect. The principal running the school, walked in thinking they were getting a product consistent like manufactured VCT. In the end because their expectations were not managed what could have been a cheerleader for polished concrete turned them into someone who is against polished concrete.