These days, when a construction company, especially small construction company, provides a bid for concrete walls or foundation walls they typically receive PDF's (portable document format) instead of plans to bid from. However, some contractors are hesitant to use PDF’s because information is often incomplete. But most end up using them to calculate the amount of concrete, steel reinforcement, and other related materials, add an amount for labor, forms, and profit and submit their price. If they are awarded the project, office staff constructs shop drawings, start planning for the construction, do layout work, and set up cost-accounting procedures. In this process, a lot of time and effort goes into estimating, planning, doing layout work, and managing concrete placements—some of it being redundant. So with this in mind the Trimble Corporation based in Santa Clara, California, decided to build onto their Tekla software (software that uniquely serves the concrete industry) to provide concrete contractors with easy-to-use software that plans for and manages all aspects of the forming and concrete placement process. Their one-of-a-kind product is useful for both small and large companies—from residential foundations to large commercial projects.

Using Constructible BIM

The concept of Building Information Modeling (BIM) goes back to the 1970s but the technology didn’t become useful for managing building projects until the early 2000s when the technology was developed better and contractors began to use it.

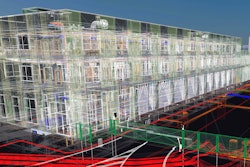

BIM makes it possible for contractors to create three dimensional digital images of their work, accurately plan for the materials they need, and collaborate with other team members throughout the life of the project. For many this happens when estimates for new work are being created. It speeds up the estimating process and facilitates the next steps in the beginning construction process; material orders, planning, doing layout work, scheduling with other trades, cost accounting, and many other features. Companies that use BIM are able to eliminate many repetitive tasks and be more productive. Also, it’s very easy to create points and send them as digital files to robotic total stations for laying out points and elevations for the structure being built. Digital files sent to robotic total stations can also be used to direct site excavation and grade preparation machines. BIM is now a part of the construction mainstream.

Constructible BIM for Formwork

From the beginning Tekla software focused on the concrete construction industry so a logical next step for them was to design software that added forming technology to their established BIM product. Andy Dickey, the cast-in-place concrete business development manager for Trimble’s structures division says they wanted the new formwork offering to be useable for big and small contractors—software that they could easily use themselves. They wanted it simple enough for contractors to quickly build their own 3D models and digitally lay out formwork with the same forming system they planned to use for the project. For small contractors, the owner is typically the one who learns how to use the software and for larger companies it’s their estimators, project engineers, or project managers who do the work. Dickey says contractors also save money using BIM software by eliminating many repetitive tasks.

In the process of construction, Tekla software takes you through several steps. The first step is typically the construction of a 3D model during the estimating phase of a project to determine areas, volumes, and lineal amounts of the materials needed for bidding the job. When the job is contracted the next step is to add the forming system chosen for the work. The software provides considerable automation to help make this step easy.

Part of the new formwork offering includes a “formwork warehouse,” where information about each recognized manufactures’ forming systems, along with some generic systems are represented. “At present we have both Peri’s and Doka’s forming systems (two of the largest forming manufactures businesses in the world) cataloged in the system, as well as a couple generic ones,” Dickey says. “Eventually we will have almost all form manufacturers products stored.” To automatically place forms for your project, you select the forming system you are using and swipe it along the digital wall or foundation wall model you created for your bid. The software provides you with a 3D view showing the forms assembled in place as they should be laid out. Work crews can use this as a shop drawing; easily sent to iPads or jobsite tablets so they can see how the forms should be assembled. If you prefer traditional formwork drawings, Tekla software can be used to automatically produce a 2D formwork drawing set too.

All forming systems include ties and bracing systems so there is common logic for the software to use. This made it easy for Tekla to automate the placement of formwork in BIM drawings. For example, when you select the form manufacturer and the forming system you are using for your project the software automatically places pins and clamps wherever you wish. It also installs braces and brackets where they should be located for the proposed wall. Dickey adds that if you change your concrete placing locations or placing schedule, brace and bracket locations may be easily changed to accommodate these changes.

Working with the program

John Sadosky, owner of A&J Concrete, Las Vegas, Nevada, specializes in commercial concrete work and occasional high-end residential. He said they started using Tekla software about three years ago to model concrete and rebar for their projects. He thinks the software is amazing and keeps getting better in terms of functionality. When they are working on estimates they create models to determine material quantities. “Having the model makes it easy to communicate with the architect and engineer for a project when we have questions or need clarification,” he says.

When they develop a model for estimating purposes they bring it to a certain point. Later, when they are contracted for the work they add to the model without redoing anything. They go on to use the model for setting points with total robotic stations, locate mistakes before construction starts, planning concrete placements, and monitoring work.

Sadosky says there are four people in his company that use the software, including himself.

Who the software is intended for

If you are a residential foundation contractor and you frequently encounter projects in hilly areas where there are frequent elevation changes for footings and forms, Tekla’s new wall forming software can be very helpful and save you a lot of planning time. Foundation contractors who specialize in custom home construction will benefit also.

For many commercial projects contractors often rely on their forming manufacturer to provide them with form layout drawings for their project. But there can be time delays when manufacturers get backed up with requests from many contractors all wanting information at the same time. This serves as an added incentive for contractors to learn how to use the software and do their own digital layouts.

If a project is large enough to include different concrete mix designs for portions of a structure, this software allows you to manage the project by mix design also. This is made possible with Trimble’s patented concrete placing, planning and management technology.

Getting started

Unwillingness to learn new technology, especially digital technology, is perhaps what slows down growth the most in the construction industry. Bigger companies try to minimize this unwillingness by hiring students fresh out of college who are trained to use it in school or by hiring professionals who already know the technology. However, smaller companies often don’t have that ability, they must provide opportunities for existing staff to be trained and coached. Recognizing this, Dickey says they offer a range of training opportunities that include class training, on-site learning, and on-line training. Companies can also pay a yearly fee for phone access to a “help desk” to assist staff when they need it. The software can either be purchased or rented.

The video below provides a quick way to visualize how the new software works: