Today’s construction projects are more complicated than ever, and a project’s success relies heavily on its attention to detail and the coordination of various moving parts. With every small oversight or clash in the design process having a substantial impact on the overall schedule, it’s no wonder that over 80% of all construction projects run longer than anticipated. Reducing these delays is no easy feat, but with an accurate, constructible model, contractors everywhere are doing just that. By leveraging constructible building information model (BIM) data alongside field technologies like robotic total stations, 3D scanners, and mixed or augmented reality (AR), contractors are not only able to identify issues early but can improve the design and execution of the project in real time.

These tools are often used for quality assurance and quality control before and during the pouring of concrete. Contractors can put anchor bolts or embeds in place and then check them before they pour concrete. They can evaluate the flatness of the floor and measure the whole area quickly in a matter of seconds before the concrete sets. As concrete is poured, adjustments can be made on the fly using these tools to make sure everything is level and that the right amount of concrete is poured, which helps save money and eliminate waste, leading to greater sustainability.

Let’s take a closer look at how contractors are using these tools on the jobsite.

Construction Layout

New digital tools are helping to seamlessly integrate construction workflows and provide layout professionals with access to constructible 3D models created by designers and detailers along with all the corresponding metadata. This data-driven approach empowers layout professionals to move beyond manual processes and leverage technology advances to meet the demands of increasingly complex projects, all while working faster and with unprecedented accuracy.

Taking a natural step beyond the capabilities of the total stations of previous decades, a robotic total station reduces the opportunity for human error and frees up contractors and layout professionals for other, higher-priority work. Controlled remotely using a tablet or controller, one person can handle even the most complex layout tasks without needing to be a trained survey professional. In addition, advanced 3D models also provide powerful visualization options, such as photographic documentation and augmented reality-style overlays. The utility of these tools is enhanced by layout software solutions designed specifically for building contractors for true connectivity between the office and the field.

3D Scanning

Scanning technology has also evolved to a point where it is easy for professionals with little or no scanning expertise to scan a job site and produce a comprehensive multi-station view of the entire work area. 3D laser scanners can deliver dense point clouds with color images of the space. Recent innovations enable the work to be reviewed and produced right in the field on a tablet as each scan is collected. This data is also recorded in the system, making it easy for contractors to go back and review the scans and ensure greater accountability for their work.

Using robotic total stations and 3D scanners together, contractors can confirm and execute a design both in the pre-construction environment and during construction. Scanners can also be used to capture what is in the concrete before it is set, creating a digital record. This way, if someone wants to install a new pipe in the future, they will know where all the rebar and post-tension cables are and can easily avoid drilling in the wrong location.

Mixed & Augmented Reality

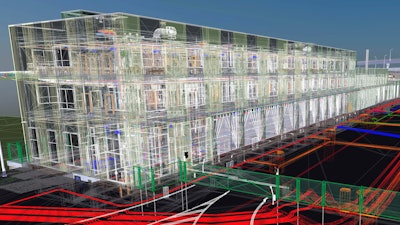

As immersive technologies like augmented reality and mixed reality (MR) continues to advance, many business leaders recognize the value of these tools as fundamental elements for visualizing complex data and supporting more information-rich experiences. A wide range of these types of extended reality solutions are providing real-world benefits to those in the concrete industry. Removing the constraints of 2D screens allows for improved quality project delivery through better collaboration and visualization. These technologies are now purpose-built to bring extended reality to the construction worksite and adapted to perform in rugged, safety-controlled industrial environments.

Augmented and mixed reality can enable new field-oriented workflows to leverage 3D content in daily work tasks to improve efficiency, productivity, and quality of work. For example, augmented reality can be used to automatically place models on site within centimeters of accuracy for positioning and measurement. Mixed reality can improve ROI by identifying potential clashes ahead of time, training new workers, and increasing collaboration between the office and the field.

With concrete, timing is critical, and contractors need to know that everything is in place for the concrete pour. Using these tools to check the model against the design allows them to make sure footings are in place, check leveling during the curing process, and make real-time adjustments before the concrete is set.

As technology in the construction industry continues to advance, integrating new software and hardware solutions can save concrete contractors both time and money. There is no better time to optimize projects and ensure success.

About the author

Bryan Williams is Portfolio Manager at Trimble.