Different types of concrete wedge anchors are manufactured for use in different applications. The only differences between the types of concrete wedge anchors are the material that they are made from and the plating or coating that is used for improving the corrosive resistance of the steel.

- Carbon Steel – the carbon steel concrete wedge anchor comes with either zinc plating for indoor applications where moisture is not present or hot-dipped galvanized coating for outdoor applications where moisture may be present.

Rule of Thumb:

The larger the diameter, the better the holding value.

- Stainless Steel 303/304 – different manufacturers use either the 303 or 304 stainless steel for their concrete wedge anchors. They are used in applications where moisture is present or where the application is submerged in water.

- Stainless Steel 316 – the highest grade of stainless steel that concrete wedge anchors are made from and are for use in submerged applications and where some chemicals are present, such as chlorine in and around swimming pools.

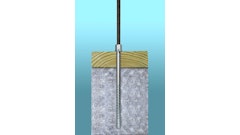

Concrete wedge anchors are made from a single bar of steel that is threaded on one end, and the other end is necked down with a permanently attached clip. They are packaged with the correct-sized nut and washer and come in nine different diameters ranging from 1/4 in. to 1-1/4 in. Each diameter of concrete wedge anchor is available in different lengths from 1-3/4 in. in the 1/4 in. diameter to 12-in. long in all diameters larger than 1/2 in.

Read about anchor bolt tolerances at ForConstructionPros.com/12281002.

The diameter of concrete wedge anchor to use for any particular application depends on the weight of the object being fastened, on the diameter of the hole size in the object being fastened, and on any specifications of diameter recommended by an engineer. The rule of thumb is that the larger the diameter than the better the holding values. Concrete Fastening Systems Inc. provides a table for holding values and technical specifications for wedge anchors online.

The length of concrete wedge anchor to use is based on the thickness of the material being fastened plus the embedment depth of the concrete wedge anchor into the concrete. Each diameter of a concrete wedge anchor has a minimum embedment depth that the anchor must be inserted into the concrete for it to obtain minimum holding values. Adding the minimum embedment of the diameter of concrete wedge anchor being used to the thickness of the material being fastened plus the thickness of the nut and washer will give the minimum length of concrete wedge anchor that should be used.

Minimum Embedment Depths by Diameter

| Wedge Anchor Diameter | Minimum Embedment |

| 3/8 in. | 1 1/2 in. |

| 1/2 in. | 2 1/4 in. |

| 5/8 in. | 2 3/4 in. |

| 3/4 in. | 3 1/4 in. |

| 7/8 in. | 3 7/8 in. |

| 1 in. | 4 1/2 in. |

| 1 1/4 in. | 5 1/2 in. |

Hole Diameter & Depth

The diameter of the hole to drill for a concrete wedge anchor is equal to the diameter of the concrete wedge anchor being installed. A 5/8” concrete wedge anchor requires a 5/8” hole to be drilled into the concrete.

The hole in the concrete needs to be drilled a minimum of 1/2” deeper than the concrete wedge anchor will penetrate into the concrete. This extra space is required to make sure that the concrete wedge anchor does not bottom out in the hole before reaching the intended embedment depth, and also allows for any dust that may be created during the installation to fall out of the way.

Concrete Wedge Anchor Installation

- With a hammer drill in the hammer mode and a carbide-tipped drill bit that meets ANSI standard B212.15 and is also the same diameter as the diameter of the concrete wedge anchor being installed, drill a hole in the concrete.

- Drill the depth of the hole a minimum of 1/2” deeper than concrete wedge anchor will penetrate, or 1/2” deeper than the minimum depth of embedment.

- Using a wire brush, compressed air or vacuum, clean the hole of all debris and dust.

- Thread the nut onto the threaded end of the concrete wedge anchor so that the top of the nut is flush with the top of the concrete wedge anchor. This will protect the threads from damage during installation.

- Insert concrete wedge anchor, clipped end first, into the predrilled hole in the concrete. If the concrete wedge anchor is being installed through a hole in a fixture, make sure that the hole diameter is larger than the diameter of the concrete wedge anchor being used.

- With a hammer, strike the nutted end of the concrete wedge anchor until a minimum of 6 threads is below the surface of the concrete or below the surface of the item being attached.

- Using your fingers, tighten the nut.

- Take a wrench and turn the nut clockwise 2 to 3 turns or until the proper torque values for the diameter of the wedge anchor being used are obtained.

About the author

Bob Carlisle has been president of Concrete Fastening Systems, Inc. for 29 years, and has been involved in the concrete anchor business since 1981.