It’s been said that the world places nearly a New York City amount of concrete every year. Within every cubic yard of this tonnage is the cement and the cloud of CO2 created in its production.

The acceptance of cements with additional limestone and higher percentages of supplemental cementitious materials (SCMs) in the mix has allowed time to prove the OPC alternatives as feasible options for concrete construction. While the production of clinker hasn’t reached net-zero yet, efforts at minimizing CO2 per cubic yard continue. Ecocem is one of the companies pulling one more lever.

Ecocem has been developing, manufacturing, and supplying low-carbon cement and construction solutions to the European market for over 20 years. They operate plants in France, the Netherlands, and Ireland with an annual production of over 2 million tons of low-carbon cement.

They’ve now moved across the pond and are looking to build a foundation here in the United States.

Announced in August 2025, Ecocem’s ACT I cement achieved certification for ASTM C1157. This certification affirmed the performance, durability, and reliability of ACT for use in the U.S. market. The milestone confirms that the product meets or exceeds the industry benchmarks for strength and durability, while reducing carbon emissions and energy use.

A ternary blended cement, while Ecocem has been active on ASTM C595 — the blended cement standard for the U.S. (the same standard that portland limestone cement falls under) — ACT isn’t covered by it yet.

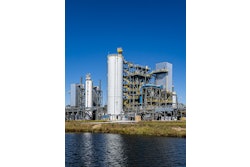

The Ecocem plant in Dunkirk.Ecocem

The Ecocem plant in Dunkirk.Ecocem

The certification announcement comes as Ecocem moves forward with its first North American project: a proposed Terminal and Milling Operation at the Port of Los Angeles. Still in the early stages of planning and review, the facility intends to establish a reliable, resilient supply chain for producing low-carbon, high-performance cement in California and support the state with the durable infrastructure required for long-term economic growth.

Ecocem’s technology was designed to significantly reduce CO2 emissions in the cement and construction industries. They report that their solution, known as ACT, can reduce the global carbon footprint of the traditional cement manufacturing process by more than half.

As Steve Bryan, managing director of Ecocem Americas, explains, California has a deficit in SCM materials. Ecocem chose California to build its North American footing to address this need. Due to sulfate conditions in the state’s soil and reactive aggregates, concrete producers need SCMs, since California has no coal-fired power plants or steel production from blast furnaces, there aren’t many options available.

Contractors in California aren’t alone. “They really don’t have anything except the natural pozzolans that have been there for 100 years…so, with its population and economic growth, there’s a need for SCMs in California and overall in the U.S.," he says. "We’re going to need and have the desire to lower clinker contents, roughly 50 percent more non-clinker materials by 2050."

The ASTM Certification

Historically, the basis of standards has been prescriptive, to have a certain strength, a certain chemical composition. Instead, people started thinking in terms of performance standards for ASTM C1157. They stepped away from thinking of how the material is made and toward performance and how it behaves in the way that cement needs to.

“It has the compressive strengths, the rheology, and the predictors of durability — all those tests are the same as conventional cements,” explains Bryan. “But they take off the restrictions in terms of chemistry and the materials of composition, etc. It’s a performance-based standard for cement.”

In short, it has allowed the industry to make concrete that performs the way it needs to.

“Anytime you can do that and look at performance, that just opens a door for innovation,” says Bryan. Ecocem is using that window to prove that their cement product can perform without having to meet the prescriptive standards such as C595 or C150.

“There’s a possibility that a new type of cement called type 1C,” he adds. This type would classify composite cements of three different materials, a minimum of 30 percent clinker and a maximum of 30 percent limestone.

Time is the proof here. Even with the certification, people will still need a portfolio of demonstration projects and the concrete’s performance over time. The company’s material has been utilized in Europe for a number of significant structures: Wembley Park outside of London, the Le Grand Paris Express, the Aviva Stadium in Dublin, and even the Olympic 2024 Athletes’ Village in Paris.

Inside an Ecocem ACT plant in Moerdijk, Netherlands. Ecocem

Inside an Ecocem ACT plant in Moerdijk, Netherlands. Ecocem

What is ACT

ACT is Ecocem’s low-carbon cement technology that was developed to reduce CO2 from cement manufacturing while delivering the necessary strength, durability, and workability required in concrete. According to their descriptions, ACT reduces cement emissions by cutting clinker content by up to 70 percent and replacing it with materials such as limestone and locally sourced SCMs. By optimizing the interaction and performance of SCMs and engineered mineral admixtures, ACT not only lowers clinker content but also enables much more efficient use of SCMs, delivering high-performance, low-carbon cement at scale.

The technology was designed to make a concrete that does not require significant modifications to existing cement and concrete production processes or change a contractor's standard practices and equipment.

Ecocem’s “bread and butter” is granulated blast furnace slag. It was their entry into the market, and where they continue to grow. They recently expanded their innovation capabilities with a new innovation center with an R&D department focused on how to use slag efficiently — the inspiration behind ACT technology.

In order to keep the workability of the concrete, they use locally available mineral admixtures to make the SCM and clinker more efficient and to achieve the rheology needed, and make the admixtures more efficient.

The Terminal

As of this writing, construction of the California terminal and milling operation has yet to break ground. Once up and running, the plant is anticipated to process 800,000 tons of raw material and is expected to produce around 775,000 tons of GGBFS annually — making an impact in the supply chain for the concrete producers and contractors in southern California.

Bryan says the need for cement alternatives has become a concern for Caltrans. There has been virtually none in the south, so much so that it’s not present in the larger projects like in the northern side of the state.

“[Caltrans] had a committee together to assess what can be done,” says Bryan. “They need these not just for decarbonization, but for technical reasons like the reactivity with the sulfate in the soils and the reactive aggregates, etc.”

The long-term, overarching goal is to help drive the industry toward composite cements and a lower clinker factor — part of this includes a goal of saving the global cement production and concrete industry 500 million tons of CO2 a year.

Construction on the terminal has not yet begun. Ecocem is in the early stages of collecting permits, and then they’ll need to return to the Board of Harbor Commissioners for final approval to build.