Early experiments with graphene predicted that it could increase the strength of concrete by up to 40%.

3D concrete printing definitely makes the list of developing technologies that are changing the world of construction. Its promise of reducing construction costs, construction time, and construction waste has inspired many builders to explore it as an alternative to traditional concrete block and poured concrete processes.

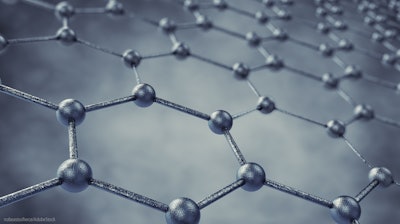

One of the latest developments in 3D concrete printing involves using graphene to reinforce concrete. While tests on the effectiveness of graphene are ongoing, testing to date has shown that graphene is very effective in improving the mechanical properties and durability of printed concrete.

The Basics of 3D Concrete Printing

3D printing, regardless of the material being printed, begins by creating a 3D model of an object within a computer. Software then directs a 3D printer to extrude a filament material in a pattern that is used to create the model in the real world.

With 3D concrete printing, the printer is guided by a computer to extrude concrete in the shape of walls, stairs, or other structures that normally would involve the laying of concrete blocks or the creation and filling of concrete forms. The process can be used to prefabricate components of a building that are transported to a site for installation or it can be brought on-site to construct walls and other components in their intended location.

By utilizing a gantry system or crane-like robotic arm and a concrete pump, a computer can guide a 3D printing head to build the interior and exterior walls of a house or other building, extruding concrete in ribbon-like trails that track with the design detailed in a blueprint or 3D model.

Using Graphene to Strengthen Printed Concrete

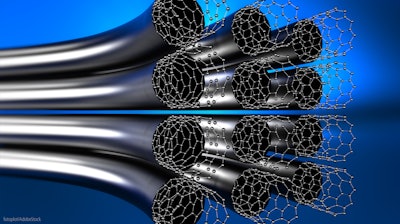

Because the process for 3D printing of concrete does not involve concrete forms, normal means of reinforcement like rebar and wire mesh cannot be used. While experimentation has involved including steel fibers in the concrete mix as well as placing steel screws in freshly printed molds, graphene is proving to be one of the more promising additives for printed concrete in terms of boosting strength.

Research on utilizing graphene in concrete was published in the "Advanced Functional Materials" journal, April 2018. With 3D concrete printing the latest to apply this concept, are there any real-world applications out there?Adobe Stock Images | by fotoplot

Research on utilizing graphene in concrete was published in the "Advanced Functional Materials" journal, April 2018. With 3D concrete printing the latest to apply this concept, are there any real-world applications out there?Adobe Stock Images | by fotoplot

Graphene has been used as an additive for a variety of 3D printing filaments, increasing the strength, stiffness, and toughness of the filament surface. When added to concrete, it has been shown to dramatically increase strength while adding other desirable benefits.

Early experiments with graphene predicted that it could increase the strength of concrete by up to 40%. Follow-up studies reveal a 146% increase in the compressive strength of concrete with the addition of graphene, as well as a 79.5% increase in flexural strength and a decrease in water permeability of almost 400%.

In addition to the benefits realized in terms of added strength and durability, the use of graphene reinforced 3D printing also greatly reduces the environmental impacts of construction projects involving concrete. The cement industry is one of the world’s leading producers of greenhouse gases, responsible for 8% of global CO2 emissions. By eliminating the need for some heavy materials and allowing for concrete to be fabricated on-site, the 3D printing of concrete reduces the need for delivery vehicles and cranes, greatly reducing a project’s carbon footprint.

In general, 3D printed concrete allows construction to happen at a faster pace with less work and less waste. As a result, it opens doors to bring the stability of concrete construction to communities where its cost has made a higher quality of housing unattainable. With the added benefits realized by adding graphene to the mix, 3D printed concrete promises to empower a revolution in safe, reliable, and affordable housing.

About the author

Fourth generation mason Matt DiBara mixed his first bag of concrete at age 9 and went on to spend most of his childhood learning the trade, eventually placing second in the national SkillsUSA masonry competition. After graduating from the University of Massachusetts with a degree in Construction Management and Environmental Design, Matt took over his family's construction business and relocated to Los Angeles. DiBara Masonry is the leading masonry and concrete company in the county, working on some of the most prestigious and well known celebrity homes in the city. Matt is also the host of The Undercover Contractor podcast and author of The Undercover Contractor.

![Strux Macrofibers 58c9b97fd4aaf[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/08/strux-macrofibers58c9b97fd4aaf1.cNEEIfY9kp.png?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)