Cracking is a natural, expected, and accepted behavior of concrete. However, cracks may affect the appearance, function, durability, service life, or more seriously, the structural integrity of the concrete. For these reasons, designers, concrete producers, and contractors are always trying to control or minimize the amount and severity of concrete cracking. However, crack-free concrete is seldom achievable, especially for standard unreinforced or reinforced concrete.

Basically, concrete cracks. That’s a fact.

For some projects, the specifications require cracks in concrete to be repaired and may specify a crack repair procedure or may simply require cracks to be repaired as directed by the engineer. Regardless of what is required by the specifications, cracks should be investigated before designing or performing repairs, especially for elevated structures. Otherwise, repairs may not address the root cause of cracks resulting in poorly repaired cracks that fail prematurely or repairs that may not restore the as-designed condition of the structure. More importantly, a proper investigation can determine if a crack is the first sign of serious trouble indicating the load-carrying capacity of the structure may be jeopardized by either a design, detailing, or construction error.

Here are some recommendations for troubleshooting concrete cracks prior to designing or performing repairs.

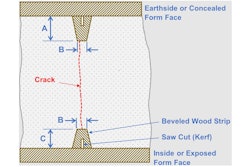

The Fundamental Cause of Cracking

There are many types of cracks related to different causes but the shared cracking mechanism for all common cracks is tension. The tensile capacity of concrete is limited for both plastic or hardened concrete. Concrete is not a ductile material; it will not stretch when subjected to tensile stresses. When the tensile stresses exceed the tensile capacity of the concrete (about 10% of the compressive strength), concrete cracks. Of course, the tensile capacity increases as freshly placed concrete hardens but while plastic and at early ages, concrete has little tensile capacity so it is very vulnerable to cracking.

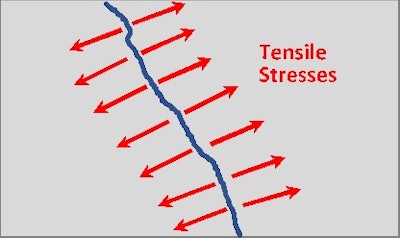

Figure 1. Red arrows shown perpendicular to the crack simulate the tensile stresses that created the crack. Determining what caused the tensile stresses is the key to determining what caused the crack and assigning a label such as plastic-shrinkage, thermal, or drying-shrinkage crack, etc.Kim Basham

Figure 1. Red arrows shown perpendicular to the crack simulate the tensile stresses that created the crack. Determining what caused the tensile stresses is the key to determining what caused the crack and assigning a label such as plastic-shrinkage, thermal, or drying-shrinkage crack, etc.Kim Basham

Typically, cracks are categized as “before hardening” while the concrete is still plastic and “after hardening” or after the concrete has hardened. Because tensile capacity increases as concrete hardens and gains strength, a third category called “early age” exists. This category refers to the time period after hardening but prior to the concrete gaining full strength. Many cracks occur when early-age concrete is subjected to tensile stresses, especially concrete volume changes associated with restrained thermal contraction (cooling) or concrete drying shrinkage.

For slabs-on-ground, restraints include the base material and reinforcing if installed, and adjacent foundations and walls if not isolated from the slab with isolation joints. For walls and elevated slabs, connecting concrete elements act as restraints that prevent volume changes of the concrete from occurring. Restraints lock the concrete in place so that volume changes of the concrete (i.e., thermal and drying shrinkage) cannot occur resulting in tensile stresses within the concrete.

Crack Investigations

Ideally, a crack investigation should always start with a site visit and a detailed visual inspection. At a minimum, do the following during the site visit:

- Create a crack map showing the locations and characteristics of the cracks. Also, show other important elements such as joints, openings, penetrations, and restraints such as foundations, walls, columns, etc.

- Measure and record crack widths and lengths. For slabs-on-ground, measure contraction joint spacings and sawcut depths.

- Take lots of photographs.

If possible, obtain and review the construction drawings and specifications including the reinforcement details and concrete cover to assist with the visual inspection and to better understand the possible causes of the cracks and the designed crack control provisions. Obtain and review the concrete mix design, batch tickets, and any placing and concrete reports that are available. For slabs-on-grade, try to obtain the sawcut timing for the contraction joints. Also, obtain concrete curing information and review the site conditions including weather during and after concrete placement. Obtain the time when cracks first appeared. Documentation should include sufficient information so others can fully understand the nature and severity of the cracking without visiting the project.

Crack Maps

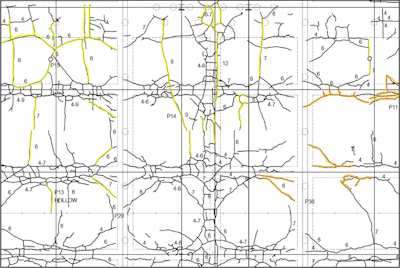

Figure 2. Example of a crack map showing crack widths in mils. Highlighted cracks (yellow and orange) indicate two levels of crack edge spalling. Not show is the crack inventory that summarized crack widths, lengths and amount of crack edge spalling per gird squares for the floor.Kim Basham

Figure 2. Example of a crack map showing crack widths in mils. Highlighted cracks (yellow and orange) indicate two levels of crack edge spalling. Not show is the crack inventory that summarized crack widths, lengths and amount of crack edge spalling per gird squares for the floor.Kim Basham

Crack maps should contain sufficient information so a detailed crack inventory can be created for the purpose of designing and estimating the cost of repairs. For example, a crack inventory can categorize and list cracks according to widths, depths, locations, cracks with and without edge spalling, or other characteristics for the purpose of assigning different repair materials and procedures for each category of crack. Be sure the crack map inventory has sufficient information to accurately estimate repair costs or for repair contractors to bid on the work. Figure 2 shows an example of a crack map for a structural slab supported by beams/girders and piles.

Photo 1. To use a crack compactor card, place on crack and algin line that matches the crack width, and read line width.Kim Basham

Photo 1. To use a crack compactor card, place on crack and algin line that matches the crack width, and read line width.Kim Basham

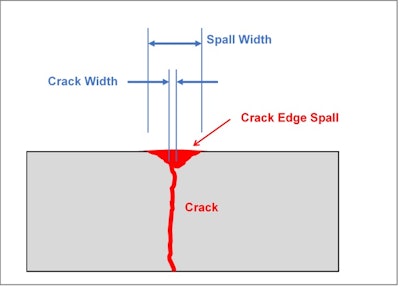

Crack Widths

Figure 3. Be sure to measure crack widths and not spall widths unless measuring both.Kim Basham

Figure 3. Be sure to measure crack widths and not spall widths unless measuring both.Kim Basham

Active or Dormant?

Determining whether cracks are active or dormant is critical for designing a crack repair, or more specifically, selecting an appropriate repair material and procedure. Active or live cracks are moving cracks or cracks that are likely to grow in width and perhaps length or open/close with changing concrete temperatures. Dormant or stable cracks are unlikely to grow in width or open/close with changing concrete temperatures. Active cracks should be repaired or sealed with flexible repair materials to accommodate future crack movements. Whereas, dormant cracks can be repaired with either flexible or rigid repair materials.

Photo 2. Using either screws or epoxy, mount the two-piece calibrated crack monitor on the concrete over the crack. The red crosshairs on the clear piece move relative to the grid on the white piece graphically showing the direction and amount of movement.Kim Basham

Photo 2. Using either screws or epoxy, mount the two-piece calibrated crack monitor on the concrete over the crack. The red crosshairs on the clear piece move relative to the grid on the white piece graphically showing the direction and amount of movement.Kim Basham

Photo 3. Digital gauges can be used to measure crack width opening and closing due to a heavy wheel load.Kim Basham

Photo 3. Digital gauges can be used to measure crack width opening and closing due to a heavy wheel load.Kim Basham

Reinforced?

Depending on type and amount, typical concrete reinforcing including steel rebars, steel fibers, and macro-synthetic fibers can control crack width movements so cracks can be considered as dormant with regards to designing a crack repair procedure. It is important to determine the type and amount of reinforcing crossing through cracks during the investigation. If needed, a rebar locator can be used to verify the presence and location of steel reinforcing.

Type of Cracks

There are two basic types of concrete cracks: intrinsic or non-structural and structural. Intrinsic are naturally occurring cracks that are related to concrete as a material such as plastic settlement and shrinkage, freezing of freshly placed concrete, crazing, thermal and drying shrinkage, seasonal temperature changes, corrosion of reinforcement, and alkali-aggregate reactions. Whereas, structural cracks are typically associated with overloads from either construction or service loads. These cracks typically require an engineer’s involvement to determine if the load carrying capacity of the structure has been jeopardized and to determine what type of repair or strengthening is required to ensure the structural integrity and safety of the structure.

Adobe Stock Images | By phatthanit

Adobe Stock Images | By phatthanit

Repairing Cracks

After determining the root and possibly, secondary causes of cracks, an appropriate crack repair material and procedure can be selected and/or performed. Part 2 of this article, addresses crack repairs and how to design or select the proper materials and procedures. Procedures addressed include: clean and fill, rout and seal/fill, epoxy and polyurethane injections, autogenous healing, and no repair. Yes, that’s correct… no repair. Look for Part 2 soon.