Digital transformation has been a key area of investment for businesses over the past decade and is expected to only continue. Even with the pandemic wreaking havoc on business spending worldwide, overall digital transformation spending was still forecasted to increase by 10% in 2020.

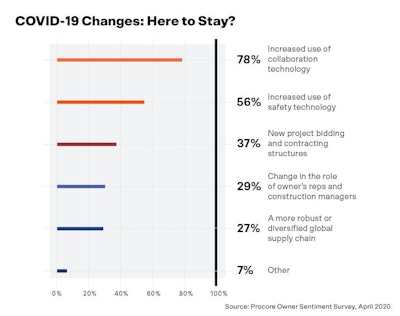

The construction industry has lagged behind other industries in this respect, being notoriously reliant on outdated technology and operating in deeply entrenched business silos. Despite this, there is still progress. The pandemic forced companies to innovate, and construction businesses that introduced safety and communication technologies are highly likely to keep them once the pandemic is over. It’s clear technology will continue to play a major role in transforming safety, communications and operations.

Procore

Procore

How the Pandemic Increased the Need for Efficiency

Prior to COVID-19, construction companies were experiencing high demand and increasing revenues, despite their slow adoption of new technologies and a lack of digital maturity. Once the pandemic hit, this changed rapidly. The construction industry lost a total of $60.9 billion in GDP in the U.S. alone, with an estimated reduction to 6.5 million jobs, down from 7.64 million since February 2020.

Furthermore, inefficient on-site workflows that relied on paper trails and outdated communication methods became even more difficult to work with once social distancing measures were implemented. As a result, businesses have been forced to look for digital solutions that can unlock new operational efficiencies and enable service delivery with reduced manpower.

Why are Construction Companies Struggling to Innovate?

The need for digitization in construction has been made clear by the pandemic and by other industries that have successfully overcome their operational challenges through the introduction of digital products and services. Construction companies, however, often work on projects with extremely different requirements. The processes and systems that are in place for one project have to be coordinated with a variety of contractors, subcontractors, suppliers, and business divisions. These projects are often one-offs and are rarely replicated. Consequently, business leaders who might be enthusiastic about digital transformation might be unsure how to go about achieving it.

3 Reasons Construction Companies Need to Digitally Transform Now

The gap between field and office workers is growing

Construction operations have always been broken down into individually operating business divisions, and slower collaboration between divisions has caused a significant increase in lead time. The enforced necessity of remote work has only made communication between teams a greater challenge.

Between offices, remote workers, contractors and suppliers, any on-site observations made regarding material quality, for instance, have to go through several communication channels before new materials can be procured. This communication chain can cause great confusion, delay delivery time and create animosity between contractors and employees.

The introduction of a unified communication channel allows construction teams to increase collaboration, aligning the different stakeholders on the requirements and schedules of each project. A digital solution also allows communication to occur in real time. Many on-site employees still use physical paper forms to take notes while inspecting the site and communicating the information on the form can take time. An integrated communications platform keeps everyone up to date and reduces the time it takes for key information to cross business divisions.

Productivity and effectiveness are key to delivering results

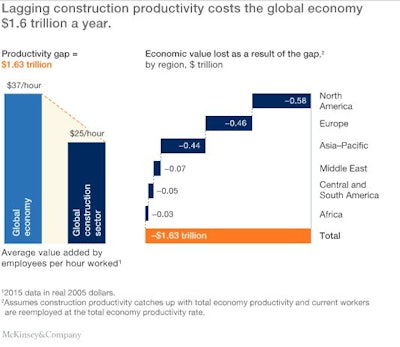

Construction businesses tend to be entrenched in outdated processes that limit productivity. McKinsey reported that productivity growth in the construction industry has increased a mere 1% a year over the last 20 years. This lags behind counterparts in other industries, who are increasing productivity at almost three times the rate. This inefficiency is estimated to cost the global economy $1.6 trillion a year.

With the demand for construction services increasing rapidly and the construction workforce aging to a large extent, efficiency and improved productivity can be the difference between an overwhelmed workforce and a satisfied clientele. McKinsey found that firms that introduced digital systems for procurement, supply-chain management, better on-site operations and increased automation had improved productivity 50% over firms that relied on analog solutions.

Through the use of technologies such as AI, IoT and VR, construction businesses can modernize each stage of their operations from planning to execution. This reduces the amount of time spent revising designs, seeking approvals and calculating the resources needed for any changes in the project.

There is an increased focus on health and safety

The pandemic has caused many people to pay more attention to health and safety standards in all types of workplaces. For construction businesses, this focus on safety and health is not new. Despite its efforts, according to the U.S. Bureau of Labor Statistics, the construction industry has one of the highest fatality rates, with 9.5 fatalities per 100,000 full-time equivalent workers. Construction companies are under pressure to minimize construction accidents by improving on-site safety and protection guidelines, and provide improved support to workers who need it.

The introduction of technologies such as exoskeletons, AR glasses and wearable monitoring devices has made achieving higher safety standards possible. When technology works in tandem with production, it can increase on-site safety standards by reducing human error and improving response in case of an adverse event. When this technology is integrated, business leaders also have a holistic view of their operation and can identify potential safety problems early.

Businesses and industries that transformed themselves early have displayed the benefits of adopting modern applications and systems. Technology has made improving safety standards, appealing to a new generation of workers and increasing operational efficiency, more achievable than ever before. Construction companies must transform and now is the time.