On a Friday night at 5:20 pm, Warfel Construction president, Matthew Hartzler, was looking at project photos when he saw a retaining wall that gave him pause. The cut behind it didn’t look safe, so he contacted Conlan Swope, VP of operations, to let him know. The conversation turned to whether or not there was a better way to use these kinds of photos to improve safety. After all, it’s not very efficient for the company president to manually identify safety hazards in site photos.

Warfel was growing. From a $58 million company in 2009, it had consistently risen to revenues greater than $225 million. Technology had become a big part of executing the company’s slogan: “Clients for Life.” If they were going to be the go-to contractor for any developer they’d worked for, the company’s leaders knew they would need the best in emerging technologies to understand what was going on at the job level, and need to use that data to drive costs down and productive quality up. One of the rare ways to accomplish both of those goals at once, and meet their obligation to people doing the work, is to improve site safety.

Hartzler’s Friday night call to Conlan came in 2019. He’d been browsing project photos on Warfel’s recently implemented Procore project management system. Procore replaced a lot of fragmented point solutions that didn’t communicate with each other. It eliminated the app log-in hopscotch and redundant data entry.

“The icing on the cake was all the integration possibilities with Procore,” says Phil Weaver, Warfel’s senior director of IT. “It integrated with our existing ERP, Viewpoint, and hundreds of other platforms, like Smartvid.io.”

Way more value from existing data

Warfel’s project people were capturing a lot of photos using Procore’s Photos tool for the company’s standard operating procedure for progress and milestone documentation. StructionSite – another application with an established Procore integration – is a project imaging platform that enhanced Warfel’s progress documentation, and its safety effort. StructionSite allows a user to locate themself on project drawings in Procore, then take a 360 photo easily with the StructionSite camera. The image is automatically tagged with Procore’s time- and plan- specific data for that location on the job.

“Smartvid.io sees that photo in Procore and ingests it into its AI (artificial intelligence) engine. There was no additional process needed from our end-user standpoint,” Weaver explains. “With those photos accessible to Smartvid.io from Procore, we’re able to start leveraging some of the advanced AI features of Smartvid.io.”

Implementing Smartvid.io was, in Weaver’s words, “easy-peasy.”

“Smartvid.io plugged right into Procore. We began exporting projects from Procore to Smarvid.io on a Friday, and Monday morning, all 45 projects were synced up and ready to go.”

With the Smartvid.io Safety Monitoring solution that Warfel deployed, the AI works like a virtual safety manager that automatically detects safety hazards in photos the contractor’s people store in Procore (Smartvid.io says it’s simple to connect its software to any repository, including Box, Egnyte, Oxblue and many others). The AI, which Smartvid.io has named “Vinnie,” can identify phases of work and risks captured in the images, which became the key to Warfel using so much more of the data those progress images capture.

For example, Vinnie analyzes a photo taken by a Warfel engineers to document work in place. In the image, an electrician stands near the top rung of a stepladder, working above the ceiling grid. Vinnie tags the image to report the risk with the person working at height in the room. The single risk is not Warfel’s primary concern (they’re not using Vinnie to spot safety violations to write up) but the frequency of this kind of risk is.

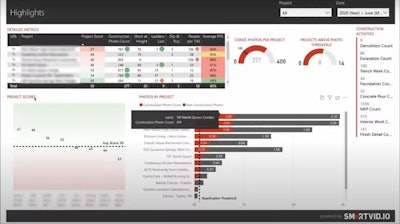

Vinnie aggregates a database of observations tagged by keywords, project, phase of work, subcontractor and other criteria. Warfel uses Microsoft Power BI to create dashboards and a safety risk assessment report from Vinnie’s data that provides the firm with cross-project benchmarking for leading risk indicators, such as workers at height, ladders by type and slip, trip and fall hazards.

Vinnie’s ability to identify context adds important nuance to their understanding of the hazards it detects. For instance, it may not be as big of a deal if workers aren’t wearing some PPE elements while doing some interior work, but it’s generally a very big deal during demolition.

Used to improve, not punish

“The information allows us to look at trends, identify particular risk areas, and benchmark ourselves in terms of performance against other contractors all across the country,” says Swope. “Over time, is this a consistent issue that we’re having in this phase of work, or with this contractor on this project?

“If you’re looking for a source to police safety or slap hands on a project, Smartvid.io can be used for that. But you’re obviously looking at lagging indicators already. What we wanted to do with safety analytics is figure out how we can make people better.

“Risk is everywhere around us. It’s not going away 100%, but how do we continue to mitigate that, and look at it as a continuous improvement process? What we did when we brought SmartVid on board, is tie together what they were seeing in the field with the prequal process. We’re evaluating subs from past project performance, safety, quality and financially.

“We wanted to look specifically at the safety measures and safety scoring for subcontractors,” Swope explains. “What caused certain subs to be more of a risk for us on projects? And on the other side of it, what made subs that were continually getting high scores on safety so safe on projects?

“We’ve used that trending information – especially during COVID – to help us educate, coach, come along side subs that were struggling, and help implement some new measures, new practices, new guidelines to improve upon safety scores that we were seeing with some of those higher-risk contractors.”

This approach yielded results in weeks. The Warfel crew started working this way with two subcontractors that consistently scored at the bottom of their safety scale.

“They were what we call ‘high-risk subs,’” says Swope. Over the last two months we’ve seen them move into a medium-risk category. Which might not seem like a drastic change, but anytime you can take somebody who was performing at a 3 and move them to a 6, that’s a big change in their risk to a project and to employees going home safely at the end of the day. That’s a huge win, and a great example of using the data to close the loop and drive behavior. Not nailing people – using the data to improve behavior.”

The AI data makes conversations with subcontractors productive because it can accurately measure the safety value of specific jobsite conditions, so there’s little question that what Warfel is suggesting will, in fact, produce the results both parties want.

For example, Warfel saw that when Vinnie identified a foreman present on site — foremen wear a different-color hardhat — the safety risk of that site was eight times less than sites without a foreman.

“That’s a huge reduction in risk, and we wanted to extend it to all of our sites,” says Swope. “So we worked with our underperforming subcontractors to find a way to get a foreman there, and as a result we saw multiple of our highest risk subcontractors move into the medium-risk category. That’s a big big change that makes a big difference, and we would have never noticed it without Smartvid.io.”

AI keeps jobs working through COVID

Vinnie adapted to the coronavirus, with Smartvid.io developing its ability to identify COVID-19 safety hazards such as “people in group” (people standing less than 6 ft. apart or congregating in groups of ten or more) and “no face mask.” These capabilities were vital to Warfel’s ability to continue working, especially during the initial government shutdowns early in the pandemic.

To keep jobsites open, Warfel had to present county authorities with its COVID-19 safety procedures and demonstrate that workers were complying. Using AI analysis of photos taken through its standard job-progress procedures, Warfel is able to monitor how well each jobsite is complying without adding personnel on-site to observe, which would increase both costs and viral transmission risk.

“We were the only job allowed to operate in one of Pennsylvania’s largest counties because we could validate our adherence to COVID-19 safety guidelines with Vinnie’s analytics,” says Swope. “That kept a lot of people working – both our own employees and a large number of subcontractors. We took great pride in that.”