The value of seal coating asphalt to preserve it and improve its aesthetic appeal are easy to understand, and one day in 1998, this simple value equation hit one young man hard, leading to a lifelong career as a paving entrepreneur and a national business footprint.

“I was 18 years old and getting ready to get done with high school,” William “Nick” Yoss said. “I was at Home Depot and saw the seal coat display, went across the street to Staples and had business cards made. Now, we have seal coating work all over the country for Home Depot, Walmart and Menards. We always subbed out pavement up until 2020, but we could not get subs with COVID-19 happening. So, we jumped into paving the same way we did the sealcoating.”

Today, Yoss is president and founder of a group of Synergy Pavement Group, a family of companies that employs 32 and delivers asphalt paving, repair and maintenance from locations in South Beloit on the Wisconsin-Illinois border and Lake Placide, Fla. Synergy Asphalt performs paving and Asphalt Maintenance Systems performs asphalt repair, maintenance and line striping.

The company tends to keep its South Beloit and Lake Plaza operations separate.

“We used to move capacity around between the two offices,” Yoss said. “It did not work very well.

Every time we get a large project, we would send a couple people down. Between the distractions that Florida may offer a northerner in the winter and time spent away from family, the arrangement did not stick. Separate crews and equipment pools deliver the full spectrum of Synergy Asphalt Group’s service offering from each office.

“We strive to be the best in pavement maintenance and asphalt paving,” Yoss said. “Today, we do everything in house—no sub work for concrete milling or pavement overlays.”

A Paving Contractor Software Stack

Scaling a company in a constrained labor market means there is one glaring top priority for Yoss.

“The biggest technology we are waiting for right now are robot employees.” Yoss quipped. That may be feasible for some disciplines with emerging technologies like robotic paving stripe pre-lining. But Spectrum Pavement Group is well past the whiteboard-and-Excel stage in the construction technology maturity curve.

The company uses multiple different software-as-a-service (SaaS) business applications to streamline its back-office processes including Clockshark, a timesheet management and capture application that caters to small and middle market businesses. This gives Yoss visibility and control over hourly time clocks for employees and crews.

Workers and supervisors in the field access Clockshark on a mobile device to log time. Supervisors can clock in and out for an entire crew or switch them from one account to the other if they do not have individual accounts. Meanwhile, back-office users or administrators use a desktop browser application to set up these accounts, collect data for accurate payroll and track and manage employees and crews. The software banks time transactions for later upload if there is no internet connection, making it ideal for a contractor working on linear assets between towns and cell towers. A combination of geofencing in Clockshark that records where employees are as they clock in and out on projects and internet protocol (IP)-based two-way radios help Yoss track where his crews and equipment are located at a given time.

Check out our IronPros Clockshark Product Snapshot Video

Synergy Pavement Group also uses a paving industry-specific enterprise resource planning (ERP) application from PavementSoft, a software company that actually shares ownership and personnel with a national paving contractor—Manassas, Va.-based Brothers Paving and Concrete. Shawn Boyce serves as secretary of PavementSoft and chief revenue officer for Brothers.

“We have designed and built out PavementSoft really to meet our own needs,” Boyce said. “That is what we use to run our field, for our crews and sales--everything runs through PavementSoft.”

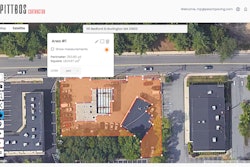

PavementSoft can be considered ERP because it gives contractors a single, digital workflow for the full value lifecycle from lead to bid to project and crew management to invoicing—from quote to cash. The supports more accurate estimating by exposing actuals. It also delivers control and the ability to modify invoices before they go out. There are integrations with both Quickbooks Desktop and Quickbooks Online. An integration with Netsuite is coming, according to Boyce. There is also a Docusign integration to support proposal submissions.

Contractors can license portions of or the entire application—PavementSoft does have an internal timeclock, for instance but a ClockShark user like Synergy Pavement Group does not need to use it.

“Our clock manager is pretty good—it does include geofencing,” Boyce said. “There are some other that are a little bit better because they do more. But ours clocks all of the employees in when they get to the job, logs them out when they leave and rolls up into Payroll reports. ClockShark and a couple others do a little bit more.”

“You can be on the job taking photos of progress, upload job pictures, generate and fill work orders, do time tracking and cost tracking,” Boyce said. “The foreman can see all the work orders and all the pictures. At the end of the day, they run a job report that shows paving cost, materials used and hours for each member of the crew, along with a profit and loss statement.”

Photos in PavementSoft can be attached to a variety of different documents ranging from invoices to estimates or internal work orders. During work-in-progress, the application automates weather alerts that affect schedule.

PavementSoft has about 400 customers across the United States and Canada, and takes on a limited number of new customers each year, positioning the software subscription like a selective fraternity or sorority.

“We are very selective,” Boyce said. “They need to be willing and able to change their philosophy about how they do things. Sometimes, the customers don’t want to do that. We start each year by taking about 100 names of companies that want to join. We pick the best 30. Then, we watch everyone’s sales improve immensely because of how quickly they can process estimates and capture cost.”

Integrated CRM and estimating can help contractors increase revenue by letting them pursue more projects without a corresponding increase in time or effort. Invoices with photos help document completion and the software even collects a net promoter score (NPS) survey to help find, fulfill and bill the next customer.

Synergy Pavement Group has a progressive technology footprint for a small contractor, but Yoss says the software is no silver bullet.

“You are not going to see a return on it right away, and you have to get everyone using it,” Yoss said.

“But PavementSoft is very simple to use. When you get your call in regarding new business, you can enter info into the application and send out an email estimate in less than five minutes. We do our maps right in the application, our coding for pricing and descriptions are all in PavementSoft. We also get the ability to update a bid with a nice map and send it to customer as a Docusign file. Once it is sent back, we can do work order off of that. As long as there are no change orders, it is one click of a button to invoice it off of the estimate.”

In projects that do involve change orders, they are hand written in the field but use a similar workflow to the estimate if they originate in the back office.

“In the field, we have tried to equip our crews with tablets,” Yoss said. “But they don’t get plugged in and charged, or they get dropped.”

Paving Equipment Technology

Synergy Pavement group is not involved in the scale of civil work that would make 3D asphalt paving, milling or compaction attractive.

“We have something similar to that on our grading and milling machines, but not on the actual paving machines,” Yoss said.

Synergy Pavement Group relies for milling on the Bomag 1330, giving them access to a number of productivity technologies including the BOMAG TELEMATIC app that:

- Monitors fuel consumption

- Tracks operating hours against duty cycle-based maintenance activities

- Captures and exposes location

- Prevents theft by triggering alerts when the equipment moves outside of a defined geomap

The company also runs LeeBoy pavers, Dynapac rollers, Case skid loaders and Sealmaster seal coating equipment. Actual autonomous equipment—those “robotic workers” Yoss mentioned, are high on his list.

“We’ve got to see more automation in our line of work,” Yoss mentioned. “Nobody wants to work out in the heat or do anything difficult. The older guys that have done it are retiring. A lot of our stuff already has some automation—BOMAG is looking to have a self-manned roller.”

@smuki - adobe.stock.com

@smuki - adobe.stock.com

Drones in Pavement Contracting

A modern contractor should be as much a technologist as a tradesperson, able to identify and use technologies to deliver value. Yoss’s credentials as this type of practical construction technologist become even more apparent given his group’s early use of drone technology.

“We were one of the early ones to start using drones and including maps with estimates,” Yoss said.

The company has relied mostly on unmanned aerial vehicles (UAVs) from DJI.

“Our first drone was through them—was a very large drone,” Yoss said. “Then we got the Mavic—which was about the size of a VHS tape, then the Mavic Mini. We could carry it anywhere, but the video footage was not very good. Most of what we use the drone footage for is really just for marketing purposes. With Pavement Soft’s program, we can get a picture of the site by satellite. But if we have a larger project where you can’t get good image off of Google Earth, we use the drone.”

Drone-related technology Yoss wants to explore next include smaller drones that can launch from a truck bed or can hover or follow another object. Less interesting is advanced drone photogrammetry software that unites the drone images with a geographic information system (GIS) or building information model or use machine vision to process photogrammetry into progress reporting.

“The progress reporting would be kind of cool,” Yoss said. “We could follow crew and use that to inform people. But we don’t do a lot where we are on the job for three weeks at a time and need to deliver those progress updates.”

Evolving Customer Expectations

Technology is a pivotal tool for Synergy Paving Group from an operational perspective, but also helps Yoss and his team meet customer expectations that are more and more demanding.

“I am seeing more of that since COVID started rather than just a change over time,” Yoss said. “Customers want things done right now—and want it done to a standard that may be difficult. Someone may sign that Docusign agreement for the work and expect you will be on the site a couple days later.”

![Patcher4 4edited[66]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2022/10/patcher4_4edited_66_.63602ddb9e727.png?auto=format%2Ccompress&fit=crop&h=167&q=70&rect=0%2C123%2C1920%2C1080&w=250)