According to the Construction Financial Management Association, general contractors’ average pre-tax net profit is between 1.4 and 2.4%. But self-performing concrete contractors have an opportunity to surpass the often-slim margins that are too common in the construction business. Why? Because they own their equipment and control their labor. The mixers and polishers are theirs, for example. The formwork fabricators and finishers work for them. If these specialty contractors can run their projects efficiently and maximize the use of their assets, then they can deliver unmatchable financial returns.

How can such contractors optimize for efficiency? Now is the time to explore and adopt generative AI.

Put AI To Work

Tools like ChatGPT and Google Bard are getting significant attention in the popular press these days. And while they are new, businesses are already putting them to work in all sorts of interesting ways. Doctors, for example, are using generative AI to help them respond to the crushing influx of email inquiries they receive from patients and find the best way to communicate an alarming test result. Marketers are using these products to quickly draft blog posts, social media content, and even whitepapers. And lawyers are using generative AI to accelerate the discovery process, helping to craft the targeted questions that drive the opposition to yield critical information.

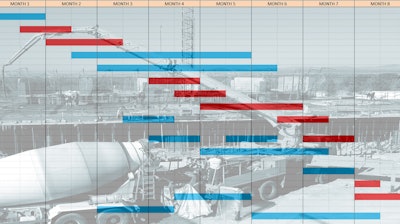

In the construction industry, one of the areas that has seen the greatest AI-powered innovation has been construction scheduling. Until recently, this was a specialty area that hadn’t seen new supporting technology introduced in decades. Traditionally, scheduling has been done using old-school tools such as Oracle P6 or Microsoft Project. These tools can be challenging to use, which means GCs – including those that self-perform concrete – have yet to have the luxury of creating and testing different construction options. Based on their many years of experience, seasoned schedulers usually create just a single project schedule. And if things change mid-project – as they often do – then the superintendents implementing those schedules work around the problems that have arisen as best they can.

ALICE Technologies

ALICE Technologies

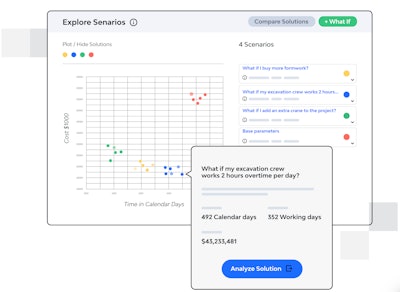

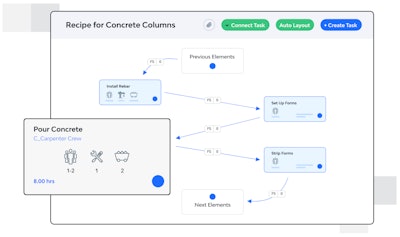

AI technology can now help contractors create and test various different construction schedules to find the most efficient way to build. With our software, ALICE users create their schedules within the platform, either from scratch or by incorporating information from prior P6 schedules. Tried and true, GCs can now use AI to create thousands of possible “variations on a theme” in an effort to discover ways to build that use people and material more efficiently, or that reduce risk. Through a process known as “construction optioneering,” they can then experiment with the schedule options they create to test what happens if they adjust certain variables. For example, if they were to use quick drying concrete vs. traditional concrete, how would this change of material impact schedule duration? How would using reusable formwork affect time and cost? Experimenting with options in this way would enable users to make data-driven decisions about exactly how they’ll build.

Generative Construction Scheduling

ALICE Technologies

ALICE Technologies

The ability to create and optimize schedules like this enables a GC to create a construction schedule that makes the best use of resources at acceptable levels of cost and risk. In doing so, it increases GCs’ profitability. It sounds remarkable – almost magical.

ALICE Technologies

ALICE Technologies

Where’s the catch?

The biggest challenge to putting such technology to work is its novelty. Traditional schedulers have sometimes used the same tools for decades and are comfortable doing what they know. Working with AI- based construction scheduling tools would require them to learn new software and adapt to new ways of thinking about the scheduling discipline. There can be a resistance to such a change, but the rewards for investing in change can be big. At the individual level, schedulers end up spending less time on drudgery and more time on evaluating interesting, strategic options. At the corporate level, enlisting generative AI can save companies millions of dollars on a single project by driving increased efficiency and avoiding the penalties and litigation that can come from missing commitments.

Today's modern tools provide a great opportunity to test for yourself and embrace it. You might just be stunned by how this new technology can help make the most of your resources on your next major construction project.