The challenge:

Effectively communicating and collaborating with several stakeholders during the construction of a 1.2-million-square-foot University of Chicago Hospital pavilion

The players:

W.E. O'Neil Construction

Gilbane Company

Rafael Viñoly Architects

The process:

Chicago-based general contractors W. E. O’Neil Construction and joint venture partners Gilbane Company wanted to more effectively collaborate with the project’s owners, design team, engineers and subcontractors on the construction of University of Chicago Hospital’s $700-million, 1.2-million-square-foot New Hospital Pavilion. The contractors decided to use a web-based and mobile Latista platform to automate their paper-based field processes. The software solution combined tablet PCs in the field with an online web server to help all stakeholders work together on resolving quality issues quickly and reduce cumbersome paperwork and communications.

"Since it’s a hospital, a paper set of drawings is more than 12 inches thick, and the amount of mechanical, electrical and plumbing progress information we share is astronomical,” said O’Neil Project Manager Brad Mayer. “When we first started, we were writing issues by hand, copying them and filing with photos. Our first 250 issues from foundation, underground MEPs and sitework filled seven binders.”

A paper QA/QC process was slow and error-prone because information was difficult to back up and not available in real time. “We couldn’t do searches, so we’d have to go through each binder in order to find previous issues,” Mayer said. Long delays between deficiency lists and reports meant that the turnaround of issue identification, correction and confirmation might last weeks; and members of the project and design teams were sometimes working with outdated information.

Creating individual inspection reports took significant time as well, said Don Brown, construction manager with Rafael Viñoly Architects. “We’d take our cameras and a piece of paper into the field and conduct an inspection. Afterward, we’d type everything up, upload the pictures to the computer and attach them to the report. The contractor would then start the corrections process. Creating the report used to take us an ungodly amount of time.”

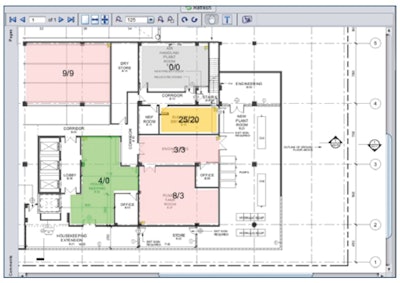

To reduce the burden of paper processes and improve collaboration between the design team, owners and subcontractors, W. E. O’Neil had the joint-venture project team standardize on Latista for inspections, notifications and reports. Tablet PCs connected to a web server gave inspectors field access to online project drawings, documents and spec-books. Digital inspection forms allowed users to assign issues to contractors, attach pictures and schedule email notifications.

Faster communication cycles also mean that the project team and subcontractors could work with up-to-date information, improving quality and reducing the need for rework. “If there are deficiencies or inspections, the subcontractors get notices nightly,” says Mayer. “We don’t have to print notifications or walk the site with the foremen.” More than 30 project and design team members and 150 subcontractors use Latista regularly to access the QA/QC rolling completion list and punchlist.

By insisting that issues are illustrated with photos before and after correction, the project and design teams improve subcontractor management with collaboration and efficiency. “Each non-conformance has a photo of why it was wrong, and the subcontractors upload photos of their correction,” says Brown. “This saves us the time of going back to the jobsite.”

“Being able to keep our notes, photos, JPGs, PDFs all in one place, that’s great," Mayer said. "Our report creation time has decreased, even though our issues have gotten more complicated.” In fact, by replacing the original paper system with a digital solution, the project has conservatively eliminated the need for 28 three-ring binders and hours of back-office work. Mayer also estimated that the team is saving cost and time equal to two full-time engineers during the project.

For Brown, the best part is not having to create or manage any reports on paper. “We’re able to keep everything in one system, and when we’re finished with an inspection in the field, we don’t have to go back to the office to do anything. Before, we might spend two to four hours making a report; with Latista it’s zero.”