Kojo has announced the launch of Kojo Prefab (prefabrication). Kojo Prefab helps contractors by connecting their prefab shop to the rest of their business.

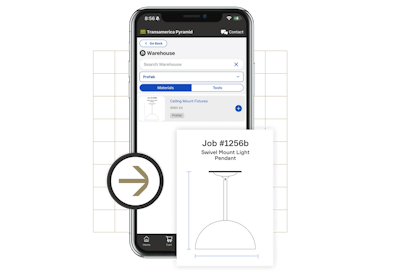

Field teams can now order prefab assemblies from the prefab shop and track the status on Kojo’s mobile app.

“As our prefab shop grew, we turned sharpie drawings into digital PDFs, but no one was using them, and they were impossible to maintain,” said Danny Blankenship, a prefab manager at United Electric. “Kojo’s Prefab not only digitizes, but the goal is for our teams to use Kojo to communicate what prefab materials are available, create POs and track deliveries - just like ordering a pizza.”

“Prefab is at the top of contractors' minds as they struggle with siloed teams and analog processes,” said Maria Davidson, CEO and founder of Kojo. “They’re increasing investments in prefabrication shops because they see the efficiency, quality control and long-term savings that come with building offsite instead of on job sites. Kojo Prefab also provides insight into how prefab directly impacts job costing.”

With this solution, Kojo Prefab customers can leverage field and prefab collaboration. Field teams can order prefab materials directly from the Kojo mobile app and track status until delivery. Prefab teams can also upload custom images and communicate production updates across teams in a flexible and customizable way without limitations.

Kojo

Kojo

Prefab is now available as part of Kojo’s expanded suite of features, which also include Procurement, Inventory Management, Tool Tracking and Accounts Payable, depending on the customer's needs.