Traditional steering wheel and lever controls can be fit with switches to put control of grade technology at your fingertips.

Traditional steering wheel and lever controls can be fit with switches to put control of grade technology at your fingertips.

A ground-up redesign of the cabs enhance visibility by eliminating the C-pillars in the back corners. The rear ROPS support was centered on the back wall of the cab, directly behind the operator.

The traditional lever and steering wheel controls are familiar, mounted in a flat-front cab (necessary to accommodate the controls). The control console adjusts to operator preference. The option to integrate automatic grade-control switches and buttons on the levers puts technology control within easy reach.

Back-of-cab C-pillar is gone from Cat graders, opening up view to the tandems.

Back-of-cab C-pillar is gone from Cat graders, opening up view to the tandems.

Joystick controls reduce hand and arm movement up to 78%. Technology options are integrated into the joysticks for seamless operation. Auto-Articulation automatically articulates the frame when the operator steers with joysticks. The angled-front cab used with joystick control improves the operator's view to the blade.

View machine information and control Cat GRADE technology on the 10-in. color monitor or touchscreen monitor.

Caterpillar says you can save up to 20% in circle-adjustment labor costs with conveniently located wear inserts and the top-adjust drawbar circle option.

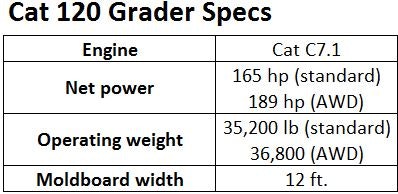

- The Cat C7.1 engine, working in ECO mode, uses up to 15% less fuel

- All-wheel drive option: 145 to 189 net hp range

- Standard tandem drive: 139 to 165 net hp range

- All-wheel-drive offers front-wheel-only creep mode for precise grading

- Seat upgrades: air suspension, heated and cooled, air-adjusted side bolsters

- Cartridge-style filtration and extended intervals saves up to 15% in maintenance costs

- Extended engine oil, hydraulic, fuel and transmission filter service intervals