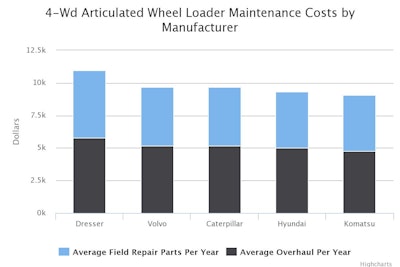

Data analysis by the publisher of the equipment Rental Rate Blue Book and resale-value Green Guide, EquipmentWatch, suggests the average annual cost for field repair parts across all manufacturers and sizes of 4WD articulated wheel loaders is $3,391, while the average yearly overhaul cost is $3,888.

Dresser takes the top spot as the most expensive loaders to maintain, and is the only made with a combined annual maintenance cost (overhaul and field repair) averaging more than $10,000. Dresser also takes the top spots for average annual field repair parts – 53% higher than the average across all manufacturers – and the highest average overhaul costs per year, 49% higher than the industry average.

Caterpillar ranks second with combined average annual loader maintenance costs of $9,692. Both field repair parts costs and overall costs are 33% more than the industry average.

Volvo follows closely behind Caterpillar with average combined yearly maintenance cost of $9,683. Volvo loaders’ field repair parts and annual overhaul costs are both 33% above the average.

EquipmentWatch analysis ranks Hyundai’s loaders the fourth most expensive to maintain, costing $9,342 on average each year. Field repair parts and overhaul costs are 28% and 29% above the average, respectively.

Komatsu loaders are the fifth most expensive to maintain, costing just over $9,000 on average for field repair and overhaul. Field repair parts and overhaul costs are 26% and 23% more than industry averages.

The EquipmentWatch analysis was created from ownership and operating-cost data collected from equipment owners and manufacturers over the past 50 years and used in calculating Rental Rate Blue Book rates. The data reflects a wide range of size classes, with models from 100 hp to greater than 500 hp. This analysis confirmed that data for each manufacturer covered the same span of sizes classes. Field repair parts include anything short of a major component overhaul or replacement. Overhaul costs include anything necessary to keep a machine functional throughout its economic life (rebuilding engines, transmissions, and other major components). Data includes models that were discontinued as long as 30 years ago, and models that are still being produced today.

Go to EquipmentWatch Intelligence

![Hcm Ax Landcros Dual Branded Logo[25]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/11/hcmaxlandcros-dual-branded-logo25.Qhg3vUCjoK.jpg?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)