Article originally published on Noria.com.

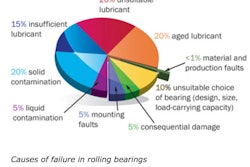

It is widely accepted that oil contamination is one of the major causes of component failure. When practicing proactive maintenance, it therefore makes sense to give oil cleanliness a high priority. By maintaining a high level of oil cleanliness, effects such as machinery failure, resultant downtime and expensive repair costs can be kept to a minimum.

There are many factors to consider when cleaning up your act. The first and most important place to start is at the source: the new oil. Oil could be contaminated when it leaves the refinery, during transportation or during the transfer to the end-user's or vendor's tanks. But more often than not, it is the manner in which the oil is stored by the user that results in new oil contamination.

(read the entire article, "How to Avoid Particulate Contamination," at Noria.com...)